Cold throw refers to the scent a candle emits when it is unlit, revealing the fragrance's strength and quality without heat. Hot throw describes the aroma released as the candle burns, offering a fuller and more intense scent experience due to the melting wax dispersing fragrance oils. Understanding the differences between cold throw versus hot throw is essential for selecting the right fragrances and wax types in candle making to ensure optimal scent performance.

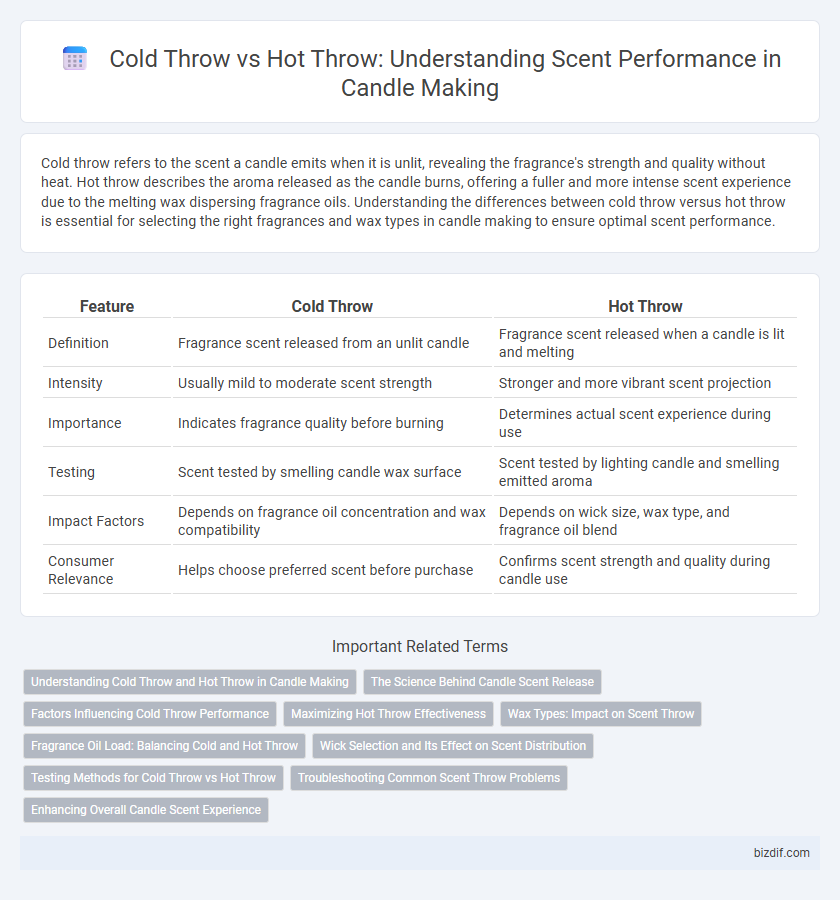

Table of Comparison

| Feature | Cold Throw | Hot Throw |

|---|---|---|

| Definition | Fragrance scent released from an unlit candle | Fragrance scent released when a candle is lit and melting |

| Intensity | Usually mild to moderate scent strength | Stronger and more vibrant scent projection |

| Importance | Indicates fragrance quality before burning | Determines actual scent experience during use |

| Testing | Scent tested by smelling candle wax surface | Scent tested by lighting candle and smelling emitted aroma |

| Impact Factors | Depends on fragrance oil concentration and wax compatibility | Depends on wick size, wax type, and fragrance oil blend |

| Consumer Relevance | Helps choose preferred scent before purchase | Confirms scent strength and quality during candle use |

Understanding Cold Throw and Hot Throw in Candle Making

Cold throw refers to the scent a candle emits when it is unlit, revealing the fragrance's strength and clarity in its solid state, which is crucial for evaluating candle quality before burning. Hot throw describes the aroma released when the candle is lit, intensifying the fragrance and dispersing it throughout the room, significantly impacting the overall sensory experience. Understanding the differences between cold throw and hot throw helps candle makers optimize fragrance load and wick selection to achieve the desired scent performance.

The Science Behind Candle Scent Release

Candle scent release varies significantly between cold throw and hot throw due to temperature-driven molecular diffusion rates. Cold throw refers to the fragrance emitted from an unlit candle, where scent molecules slowly evaporate at room temperature, resulting in a subtle aroma. Hot throw occurs when the candle is burning, as heat increases the volatility of fragrance oils, intensifying scent dispersion and enabling a stronger olfactory experience.

Factors Influencing Cold Throw Performance

Cold throw performance in candle making is influenced by the type and concentration of fragrance oils, wax composition, and curing time. Natural waxes like soy typically exhibit stronger cold throws, while synthetic additives may enhance scent release. Proper curing allows the wax to fully absorb the fragrance, optimizing the cold throw intensity before lighting.

Maximizing Hot Throw Effectiveness

Maximizing hot throw effectiveness in candle making involves selecting high-quality fragrance oils with a high flash point and proper curing times to ensure optimal scent release when the candle is lit. Using the correct wax type and maintaining the ideal wick size improve fragrance diffusion, enhancing the hot throw without sacrificing burn quality. Avoid overheating the wax to retain fragrance integrity and achieve a stronger, long-lasting aroma.

Wax Types: Impact on Scent Throw

Different wax types significantly influence the cold throw and hot throw in candle making, with soy wax generally providing a strong cold throw due to its excellent fragrance retention, while paraffin wax excels in hot throw thanks to its higher melting point that releases scent more effectively when heated. Beeswax often shows a subtle cold throw but a warm, natural aroma during hot throw, attracting those who prefer milder scents. Understanding the interaction between wax types and fragrance oils is essential for optimizing scent diffusion and creating candles with desired aromatic intensity.

Fragrance Oil Load: Balancing Cold and Hot Throw

Fragrance oil load plays a crucial role in balancing cold throw and hot throw in candle making, as an optimal percentage ensures both scent strength when unlit and when burning. Typically, fragrance oil loads range from 6% to 10%, with higher loads enhancing hot throw but risking scent suppression or wax issues that reduce cold throw effectiveness. Achieving the right balance involves testing oil percentages specific to wax type and fragrance characteristics to maximize olfactory impact at room temperature and during combustion.

Wick Selection and Its Effect on Scent Distribution

Wick selection in candle making significantly influences both cold throw and hot throw scent distribution, as an appropriately sized wick ensures optimal wax melt pool and fragrance release. A wick that is too small may restrict the hot throw by producing an insufficient melt pool, while a wick too large can cause excessive soot and uneven scent diffusion. Understanding the wick's burn characteristics and its compatibility with the wax and fragrance load enhances the balance between cold and hot throw performance, maximizing aromatic impact.

Testing Methods for Cold Throw vs Hot Throw

Testing methods for cold throw in candle making involve evaluating the scent strength of the candle when unlit by placing the candle in a closed room or scent jar to assess fragrance diffusion at room temperature. Hot throw testing requires lighting the candle, allowing the wax to melt and release fragrance, and measuring scent intensity and distribution during burning with tools such as scent sniff jars or sensory panels. Accurate evaluation of both cold and hot throw helps optimize fragrance load and wax formulation to achieve desired scent performance in finished candles.

Troubleshooting Common Scent Throw Problems

Cold throw in candle making refers to the scent released when the candle is unlit, which may be weak if the wax-to-fragrance ratio is incorrect or the fragrance oil is not well blended. Hot throw measures the scent emitted when the candle is burning, often impacted by factors such as wick size, fragrance load, and wax temperature during pouring. Troubleshooting common scent throw problems involves adjusting fragrance load between 6-10%, selecting an appropriate wick to ensure proper burn, and curing candles for 1 to 2 weeks to enhance both cold and hot throw intensity.

Enhancing Overall Candle Scent Experience

Cold throw refers to the fragrance released by a candle when it is unlit, providing an initial scent preview, while hot throw is the aroma emitted during burning, intensifying the fragrance experience. Maximizing hot throw involves selecting high-quality fragrance oils and optimal wax blends to ensure a strong, even scent distribution throughout the room. Understanding the balance between cold and hot throw is essential for creating candles that offer a consistent and immersive olfactory experience.

Cold throw vs Hot throw Infographic

bizdif.com

bizdif.com