Dye chips offer precise color control and are easy to measure for consistent candle coloring, making them ideal for small batches or craft projects. Liquid dyes blend quickly and evenly into molten wax, providing vibrant and intense hues suitable for large-scale candle production. Both dye forms are compatible with various wax types, but selection depends on convenience, color intensity, and project scale.

Table of Comparison

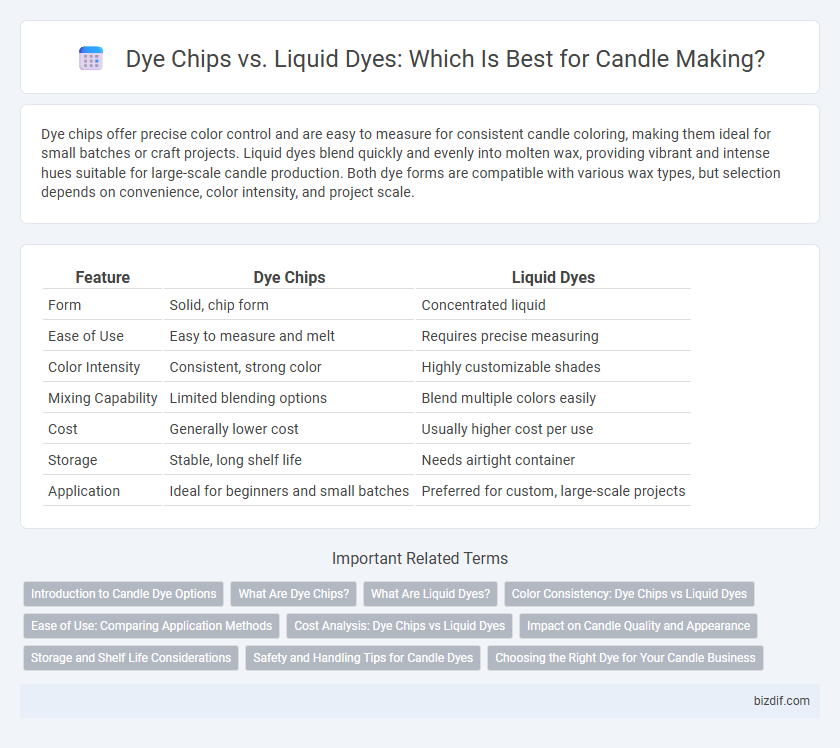

| Feature | Dye Chips | Liquid Dyes |

|---|---|---|

| Form | Solid, chip form | Concentrated liquid |

| Ease of Use | Easy to measure and melt | Requires precise measuring |

| Color Intensity | Consistent, strong color | Highly customizable shades |

| Mixing Capability | Limited blending options | Blend multiple colors easily |

| Cost | Generally lower cost | Usually higher cost per use |

| Storage | Stable, long shelf life | Needs airtight container |

| Application | Ideal for beginners and small batches | Preferred for custom, large-scale projects |

Introduction to Candle Dye Options

Candle dye options include dye chips and liquid dyes, each offering unique benefits for coloring wax. Dye chips provide concentrated, vibrant hues and precise color control, melting evenly for consistent distribution in candles. Liquid dyes, dissolved directly into melted wax, enable quick mixing and smooth color blending, ideal for achieving subtle shades or layering effects.

What Are Dye Chips?

Dye chips are solid, concentrated colorants specifically designed for candle making, offering consistent and vibrant hues when melted into wax. Unlike liquid dyes that require careful measurement, dye chips provide ease of use with minimal waste, as they can be portioned precisely for each batch. Their formulation ensures excellent color retention and compatibility with various wax types, making them a preferred choice for hobbyists and professional candle makers alike.

What Are Liquid Dyes?

Liquid dyes are concentrated, color-rich solutions designed specifically for candle making to provide consistent and vibrant hues. They blend easily into melted wax, ensuring even color distribution without altering the candle's texture or burning properties. Unlike dye chips that require melting and blending, liquid dyes offer precise color control and are ideal for achieving smooth, uniform finishes in both paraffin and soy wax candles.

Color Consistency: Dye Chips vs Liquid Dyes

Dye chips offer superior color consistency due to their solid, pre-measured form that ensures uniform melting and blending throughout the wax. Liquid dyes, while convenient, can vary in saturation depending on the amount added and the temperature of the wax, potentially leading to uneven coloring. For artisans seeking reliable repeatability in their candles' hues, dye chips provide a more stable and predictable coloring solution.

Ease of Use: Comparing Application Methods

Dye chips offer a straightforward melting process where the chips dissolve uniformly in melted wax, ensuring consistent color distribution without additional measuring. Liquid dyes require precise dosing with droppers or pipettes to avoid oversaturation, demanding more careful handling for accurate color intensity. Both options allow customization, but dye chips simplify application by eliminating extra tools and reducing the risk of uneven coloring.

Cost Analysis: Dye Chips vs Liquid Dyes

Dye chips generally offer a lower cost per pound compared to liquid dyes, making them more economical for large-scale candle production. Liquid dyes provide better color control and easier blending but often come at a higher price point and may require more precise measurement tools. Considering material costs and production efficiency, dye chips tend to be the preferred choice for cost-conscious candle makers.

Impact on Candle Quality and Appearance

Dye chips provide consistent and vibrant color intensity by evenly distributing pigments throughout the wax, resulting in a polished, opaque finish ideal for pillar and container candles. Liquid dyes offer greater color customization and easier blending, producing translucent, luminous hues that enhance gel and soy wax candles' aesthetic appeal. The choice between dye chips and liquid dyes significantly influences the candle's visual quality and burn characteristics, as liquid dyes can sometimes affect scent throw while dye chips maintain wax integrity.

Storage and Shelf Life Considerations

Dye chips offer longer shelf life and more stable storage conditions, as they are less prone to degradation caused by heat or light exposure compared to liquid dyes. Liquid dyes typically require airtight containers and cool, dark storage to prevent evaporation and color fading, often lasting significantly shorter than dye chips. Proper storage of dye materials maximizes their effectiveness in candle making by maintaining vibrant, consistent colors over time.

Safety and Handling Tips for Candle Dyes

Dye chips offer safer handling due to their solid form, reducing the risk of spills and skin contact compared to liquid dyes, which can be more hazardous and require careful measurement to avoid staining. Use gloves and protective eyewear when working with both types to prevent irritation, and ensure proper ventilation to avoid inhaling fumes, especially with liquid dyes. Store dyes in tightly sealed containers away from heat and direct sunlight to maintain their stability and prevent accidental exposure.

Choosing the Right Dye for Your Candle Business

Selecting the ideal dye for your candle business depends on factors such as ease of blending, color intensity, and consistency. Dye chips provide vibrant, uniform colors and are favored for their simplicity and longer shelf life, while liquid dyes offer versatility and smoother integration into wax, ideal for custom color mixing. Evaluating your production process and desired aesthetic will guide you in choosing between the reliable saturation of dye chips and the flexible blending capabilities of liquid dyes.

Dye chips vs Liquid dyes Infographic

bizdif.com

bizdif.com