Scent throw and burn time are two critical factors to consider in candle making, as they directly impact the overall experience and satisfaction. Scent throw refers to how well a candle disperses fragrance in a room, with hot throw indicating scent released when burning and cold throw referring to the fragrance when unlit. Balancing scent throw with burn time ensures candles provide a lasting aroma without sacrificing the longevity of the burn, often requiring careful selection of wax types, fragrance oils, and wick size.

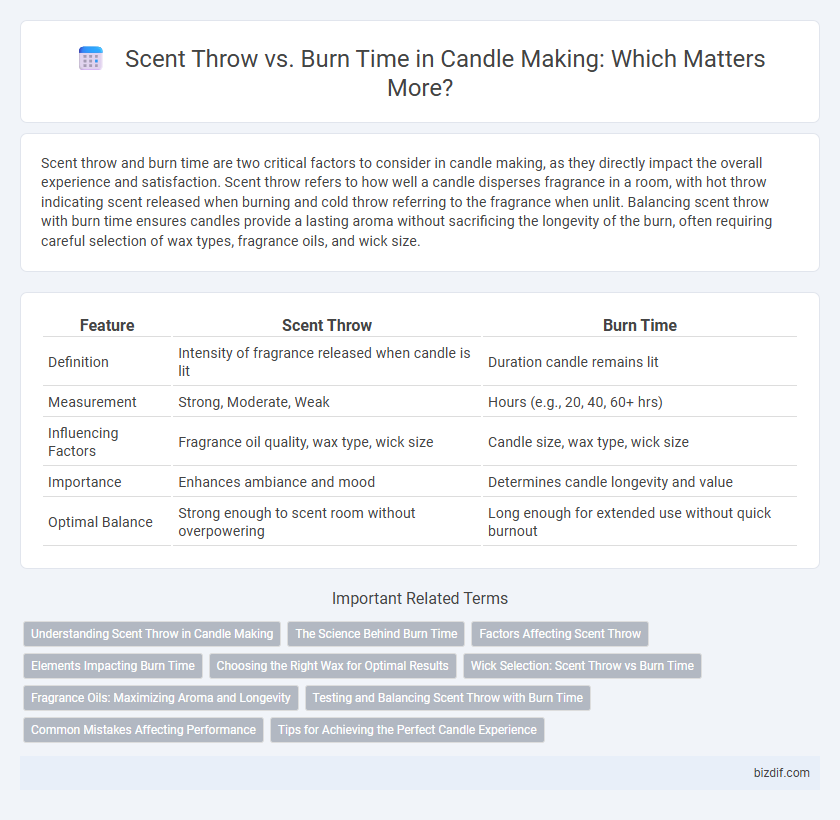

Table of Comparison

| Feature | Scent Throw | Burn Time |

|---|---|---|

| Definition | Intensity of fragrance released when candle is lit | Duration candle remains lit |

| Measurement | Strong, Moderate, Weak | Hours (e.g., 20, 40, 60+ hrs) |

| Influencing Factors | Fragrance oil quality, wax type, wick size | Candle size, wax type, wick size |

| Importance | Enhances ambiance and mood | Determines candle longevity and value |

| Optimal Balance | Strong enough to scent room without overpowering | Long enough for extended use without quick burnout |

Understanding Scent Throw in Candle Making

Scent throw in candle making refers to the ability of a candle to disperse fragrance throughout a room, which depends on factors like wax type, fragrance oil load, and wick size. Optimal scent throw requires balancing fragrance concentration and consistent burn temperature to maximize aroma diffusion without sacrificing burn time. Understanding these elements helps crafters create candles that emit a strong scent while maintaining an efficient and long-lasting burn.

The Science Behind Burn Time

Burn time in candle making depends heavily on the type of wax, wick size, and candle diameter, as these factors influence the rate of fuel consumption. Scent throw, the ability of a candle to disperse fragrance, often competes with burn time because higher fragrance load can alter wax melting characteristics and wick performance. Understanding the science behind burn time involves analyzing how heat transfer within the wax pool affects both fragrance diffusion and combustion efficiency, ultimately balancing scent intensity with longevity.

Factors Affecting Scent Throw

Scent throw in candle making is influenced by wax type, fragrance oil load, and wick size, which collectively impact how well the scent disperses in the environment. The melting temperature of wax affects the wax pool size, directly altering scent release, while fragrance oils with higher flash points tend to provide longer-lasting aromas. Proper wick selection ensures optimal combustion, maximizing scent diffusion without reducing overall burn time.

Elements Impacting Burn Time

Burn time in candle making is influenced by factors such as wax type, wick size, and fragrance load, with natural soy wax offering longer burns compared to paraffin. Scent throw depends largely on the fragrance oil concentration and how evenly it disperses during burning, which can be affected by wick selection and ambient temperature. Balancing scent throw and burn time requires optimizing these elements to ensure a consistent, long-lasting fragrance experience without compromising burn efficiency.

Choosing the Right Wax for Optimal Results

Choosing the right wax critically influences both scent throw and burn time in candle making. Soy wax offers a strong cold and hot scent throw while maintaining longer burn times, making it ideal for scented candles. Paraffin wax delivers intense fragrance release but burns faster, whereas beeswax burns slow with subtle aroma, balancing longevity and scent intensity.

Wick Selection: Scent Throw vs Burn Time

Wick selection plays a crucial role in balancing scent throw and burn time in candle making, as the right wick size ensures optimal wax melting and fragrance release without causing excessive soot or rapid burning. Using a wick that is too large may enhance scent throw but shortens burn time due to faster wax consumption, while a smaller wick extends burn time but may result in a weaker fragrance output. Choosing the appropriate wick type and size for the specific wax and fragrance load maximizes both scent diffusion and candle longevity.

Fragrance Oils: Maximizing Aroma and Longevity

Fragrance oils in candle making are carefully selected to optimize scent throw and extend burn time, ensuring a rich aromatic experience. High-quality fragrance oils with proper concentration enhance the candle's ability to emit strong, lasting scents without compromising burn duration. Balancing oil type and wick size is crucial for maximizing both fragrance diffusion and candle longevity.

Testing and Balancing Scent Throw with Burn Time

Testing scent throw involves measuring the fragrance intensity both cold and hot to ensure optimal aroma release throughout the candle's lifespan. Balancing scent throw with burn time requires adjusting fragrance load and wax formulation to maintain consistent scent diffusion without compromising the candle's duration. Precise testing protocols help achieve an ideal harmony between strong fragrance impact and extended burn time for the best user experience.

Common Mistakes Affecting Performance

Common mistakes affecting candle performance include using low-quality fragrance oils that weaken scent throw and choosing wick sizes that burn too quickly, reducing burn time. Overloading candles with fragrance oils can lead to poor scent diffusion and uneven burning, while insufficient curing time often results in muted aromas and shorter flames. Proper balance of high-quality oils, correct wick sizing, and adequate curing ensures optimal scent throw and extended burn time in candle making.

Tips for Achieving the Perfect Candle Experience

Maximizing scent throw while maintaining an optimal burn time involves selecting high-quality fragrance oils with strong cold and hot throw characteristics and using the correct wick size to ensure even melting. Using a soy or paraffin wax blend can balance scent diffusion and burn duration, while maintaining the recommended fragrance load of 6-10% ensures the candle retains fragrance without compromising burn stability. Proper curing time of 1-2 weeks enhances scent throw, and trimming wicks to 1/4 inch before each burn prevents excessive soot and extends burn life.

Scent throw vs Burn time Infographic

bizdif.com

bizdif.com