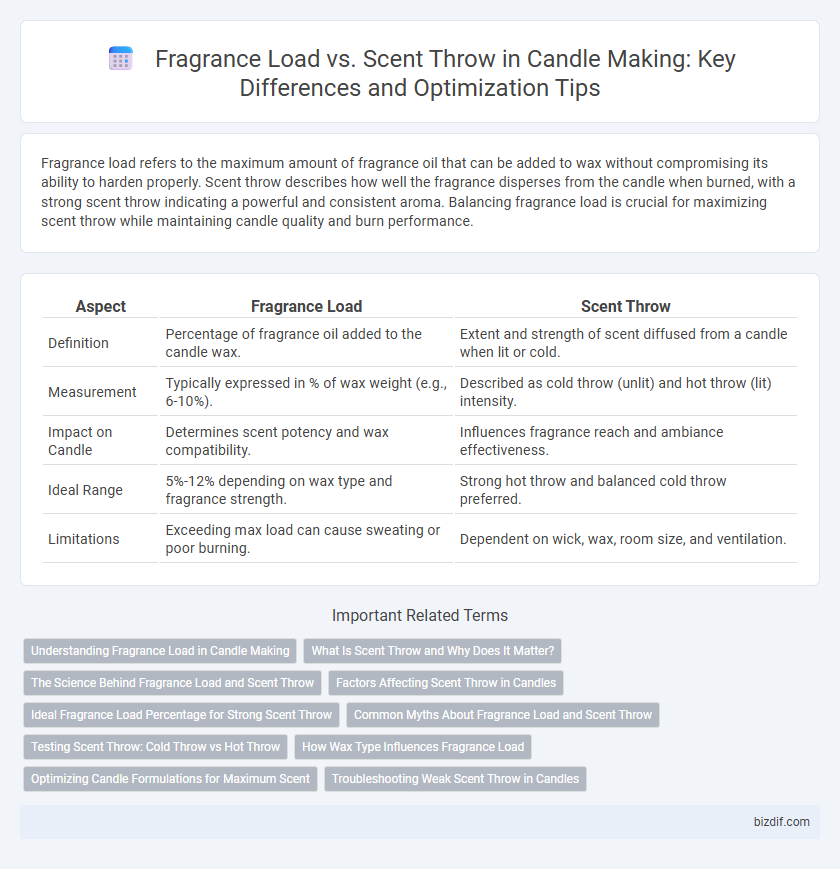

Fragrance load refers to the maximum amount of fragrance oil that can be added to wax without compromising its ability to harden properly. Scent throw describes how well the fragrance disperses from the candle when burned, with a strong scent throw indicating a powerful and consistent aroma. Balancing fragrance load is crucial for maximizing scent throw while maintaining candle quality and burn performance.

Table of Comparison

| Aspect | Fragrance Load | Scent Throw |

|---|---|---|

| Definition | Percentage of fragrance oil added to the candle wax. | Extent and strength of scent diffused from a candle when lit or cold. |

| Measurement | Typically expressed in % of wax weight (e.g., 6-10%). | Described as cold throw (unlit) and hot throw (lit) intensity. |

| Impact on Candle | Determines scent potency and wax compatibility. | Influences fragrance reach and ambiance effectiveness. |

| Ideal Range | 5%-12% depending on wax type and fragrance strength. | Strong hot throw and balanced cold throw preferred. |

| Limitations | Exceeding max load can cause sweating or poor burning. | Dependent on wick, wax, room size, and ventilation. |

Understanding Fragrance Load in Candle Making

Fragrance load in candle making refers to the maximum amount of fragrance oil that wax can hold without compromising the candle's performance or safety. Properly balancing fragrance load ensures an optimal scent throw, where the scent disperses effectively both when the candle is unlit (cold throw) and burning (hot throw). Exceeding recommended fragrance load can lead to issues like poor burning, excessive smoke, or fragrance oil seepage.

What Is Scent Throw and Why Does It Matter?

Scent throw refers to the ability of a candle to disperse fragrance throughout a room, significantly influenced by the fragrance load--the percentage of fragrance oil added to the wax. A higher fragrance load typically results in a stronger scent throw, enhancing the candle's aroma diffusion both when unlit (cold throw) and burning (hot throw). Optimizing scent throw is essential for candle makers to ensure customer satisfaction by delivering a consistent and appealing fragrance experience.

The Science Behind Fragrance Load and Scent Throw

Fragrance load refers to the percentage of fragrance oil added to the wax, directly impacting the scent throw, which is how well the fragrance disperses when the candle is lit. Optimal fragrance load varies by wax type, typically ranging from 6% to 12%, balancing scent intensity without quality degradation or poor burn performance. The interaction between fragrance oil chemistry and wax composition influences evaporation rate and scent diffusion, critical factors in achieving a strong cold and hot scent throw.

Factors Affecting Scent Throw in Candles

Fragrance load in candle making determines the concentration of fragrance oils mixed into the wax, directly influencing the scent throw, which is the candle's ability to disperse aroma when burned. Factors affecting scent throw include the type of wax used, with soy and paraffin offering different scent retention and release properties, the quality and concentration of fragrance oils, and the wick size, which controls the heat and burn rate. Proper curing time also enhances scent throw by allowing the fragrance oils to bind fully with the wax, ensuring a stronger and longer-lasting aroma.

Ideal Fragrance Load Percentage for Strong Scent Throw

Ideal fragrance load in candle making typically ranges from 6% to 10%, balancing strong scent throw without compromising wax quality. Exceeding this percentage may lead to poor burning performance or fragrance oil sweating, while lower loads can result in weak scent diffusion. Optimizing fragrance load ensures maximum scent throw during cold and hot conditions, enhancing overall candle experience.

Common Myths About Fragrance Load and Scent Throw

Many beginners mistakenly believe higher fragrance load always guarantees stronger scent throw, but exceeding the wax's recommended fragrance load can cause poor scent dispersal or candle defects. Optimal fragrance load varies by wax type, commonly ranging between 6% and 10%, ensuring a balanced burn and effective scent release. Properly curing candles also plays a crucial role in maximizing scent throw regardless of fragrance load.

Testing Scent Throw: Cold Throw vs Hot Throw

Fragrance load refers to the percentage of fragrance oils added to candle wax, directly impacting the scent throw, which measures how well a candle disperses fragrance. Testing scent throw involves evaluating both cold throw, the fragrance emitted when the candle is unlit, and hot throw, the scent released when the candle is burning. Optimizing fragrance load is essential for maximizing strong cold and hot throws without compromising the wax's burning quality or causing scent fading.

How Wax Type Influences Fragrance Load

Different wax types impact fragrance load capacity, directly affecting the scent throw of candles. Soy wax typically holds fragrance oils up to 10-12%, offering a clean, moderate scent throw, while paraffin wax allows higher fragrance loads, often reaching 10-15%, resulting in a stronger scent emission. Beeswax has a lower fragrance load capacity, usually under 6%, which limits its scent throw but offers a natural, subtle aroma.

Optimizing Candle Formulations for Maximum Scent

Optimizing candle formulations for maximum scent involves balancing fragrance load with scent throw to enhance both cold and hot scent release without compromising wax stability. Typical fragrance load ranges from 6% to 10%, where exceeding this can cause poor wax cure and scent diffusion issues. Selecting high-quality fragrance oils with strong olfactory properties ensures a robust scent throw, maximizing fragrance dispersion during candle burning.

Troubleshooting Weak Scent Throw in Candles

Fragrance load directly impacts scent throw, with typical candle waxes accommodating 6-10% fragrance oil for optimal aroma diffusion. Weak scent throw often results from low fragrance concentration, improper curing time, or incompatible wax and fragrance combinations. Increasing fragrance load cautiously and ensuring adequate curing can enhance the scent throw without compromising candle burn quality.

Fragrance load vs Scent throw Infographic

bizdif.com

bizdif.com