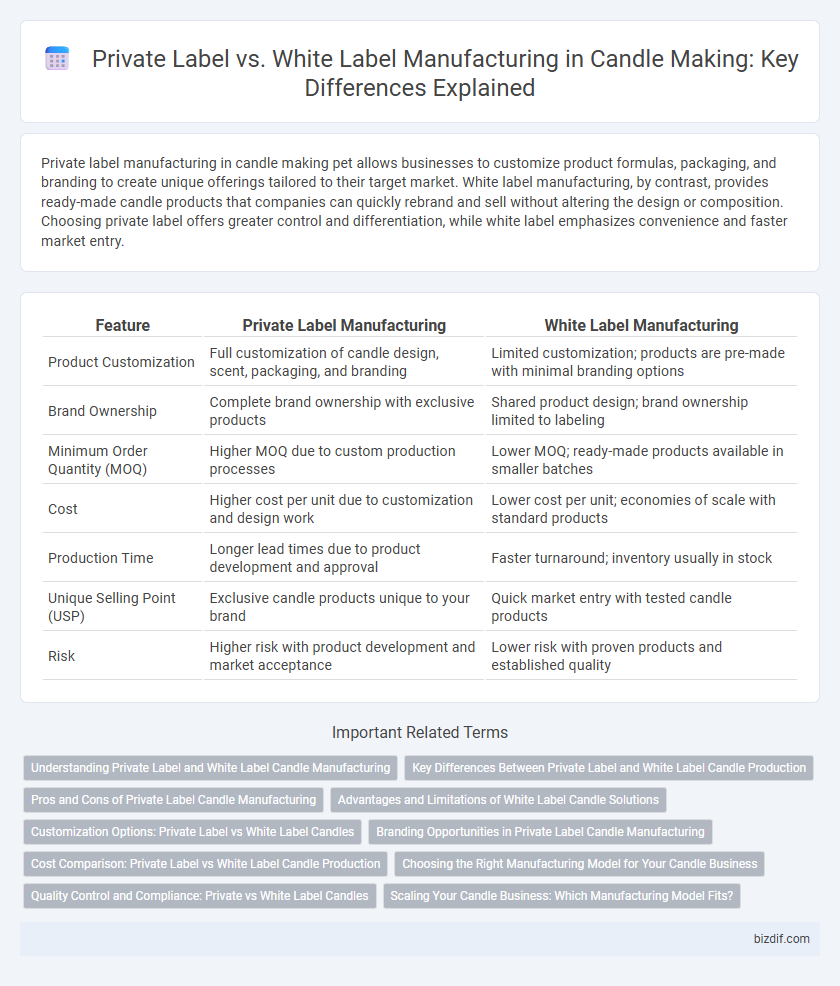

Private label manufacturing in candle making pet allows businesses to customize product formulas, packaging, and branding to create unique offerings tailored to their target market. White label manufacturing, by contrast, provides ready-made candle products that companies can quickly rebrand and sell without altering the design or composition. Choosing private label offers greater control and differentiation, while white label emphasizes convenience and faster market entry.

Table of Comparison

| Feature | Private Label Manufacturing | White Label Manufacturing |

|---|---|---|

| Product Customization | Full customization of candle design, scent, packaging, and branding | Limited customization; products are pre-made with minimal branding options |

| Brand Ownership | Complete brand ownership with exclusive products | Shared product design; brand ownership limited to labeling |

| Minimum Order Quantity (MOQ) | Higher MOQ due to custom production processes | Lower MOQ; ready-made products available in smaller batches |

| Cost | Higher cost per unit due to customization and design work | Lower cost per unit; economies of scale with standard products |

| Production Time | Longer lead times due to product development and approval | Faster turnaround; inventory usually in stock |

| Unique Selling Point (USP) | Exclusive candle products unique to your brand | Quick market entry with tested candle products |

| Risk | Higher risk with product development and market acceptance | Lower risk with proven products and established quality |

Understanding Private Label and White Label Candle Manufacturing

Private label candle manufacturing involves creating custom-designed candles specifically tailored to a retailer's brand, allowing unique scents, packaging, and branding elements that differentiate the product in the market. White label candle manufacturing offers pre-made, generic candle products that retailers can brand and sell under their own label with minimal customization, providing a faster time-to-market solution. Private label gives greater control over product innovation and exclusivity, while white label emphasizes convenience and scalability in candle production.

Key Differences Between Private Label and White Label Candle Production

Private label candle manufacturing involves creating custom-designed candles tailored to a specific brand's unique specifications, enabling full control over product features, packaging, and branding. White label candle production offers pre-made, generic candle products that companies can rebrand with their own labels, providing a quicker and more cost-effective market entry. Key differences include the level of customization, production control, and branding exclusivity, with private label allowing bespoke creations and white label focusing on standard products with minimal modification.

Pros and Cons of Private Label Candle Manufacturing

Private label candle manufacturing offers businesses the advantage of full customization in fragrance, design, and packaging, allowing for unique brand identity and differentiation in the market. However, it requires higher initial investment and longer production lead times compared to white label options, which can be a barrier for startups or small-scale entrepreneurs. The control over product quality and exclusivity in private label manufacturing often results in higher profit margins despite the increased complexity in supply chain management.

Advantages and Limitations of White Label Candle Solutions

White label candle manufacturing offers businesses the advantage of quick market entry with pre-designed, tested products, reducing development time and initial costs. Limitations include limited customization options and potential brand differentiation challenges, as the same products may be available to multiple retailers. This approach benefits those prioritizing efficiency and cost-effectiveness over unique product development.

Customization Options: Private Label vs White Label Candles

Private label candle manufacturing offers extensive customization options, including unique scents, personalized packaging, and exclusive branding tailored to a client's specifications. White label candles, however, come pre-made with limited customization, typically only allowing minor changes such as label adjustments. Choosing private label manufacturing provides more control over product differentiation and brand identity in the competitive candle market.

Branding Opportunities in Private Label Candle Manufacturing

Private label candle manufacturing offers extensive branding opportunities, allowing businesses to customize product designs, scents, and packaging to reflect their unique brand identity. This approach enables companies to differentiate their candles in a competitive market, fostering strong customer loyalty through personalized branding elements. Unlike white label manufacturing, private label solutions empower brands to control every detail, enhancing market presence and perceived value.

Cost Comparison: Private Label vs White Label Candle Production

Private label candle manufacturing typically incurs higher costs due to customized formulations, branding, and packaging tailored to the client's specifications. White label candle production benefits from economies of scale, offering lower prices as manufacturers produce pre-made, generic candles sold under various brand names. Choosing between private label and white label manufacturing depends heavily on budget constraints and the desired level of product differentiation in candle making.

Choosing the Right Manufacturing Model for Your Candle Business

Private label manufacturing allows candle brands to customize scents, packaging, and formulations, offering unique products that reflect their brand identity. White label manufacturing provides ready-made candle products that are rebranded with minimal customization, enabling faster market entry and lower startup costs. Selecting the right model depends on your business goals, budget, and desired level of product differentiation in the competitive candle market.

Quality Control and Compliance: Private vs White Label Candles

Private label candle manufacturing offers rigorous quality control and customization tailored to specific brand standards, ensuring compliance with safety regulations and certifications such as ASTM F2417 and CPSIA. White label candles, produced in bulk for multiple brands, often follow general quality protocols but may lack the personalized inspection processes that address unique requirements. Choosing private label manufacturing provides greater assurance in meeting regulatory demands and maintaining consistent product quality across batches.

Scaling Your Candle Business: Which Manufacturing Model Fits?

Private label manufacturing offers candle businesses the advantage of custom product formulation and branding, enabling greater differentiation and control as the company scales. White label manufacturing provides ready-made candle products that can be quickly branded and sold, ideal for rapid market entry with lower upfront costs. Choosing between private and white label manufacturing depends on your growth strategy, desired product uniqueness, and investment capacity for scaling your candle business.

Private label manufacturing vs White label manufacturing Infographic

bizdif.com

bizdif.com