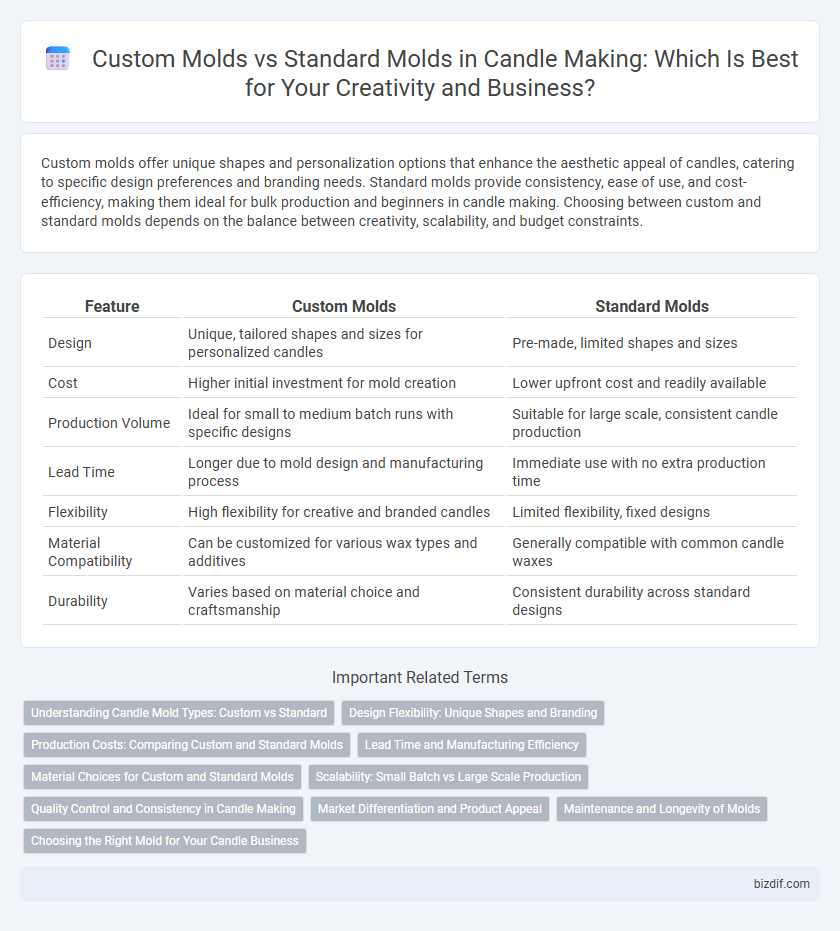

Custom molds offer unique shapes and personalization options that enhance the aesthetic appeal of candles, catering to specific design preferences and branding needs. Standard molds provide consistency, ease of use, and cost-efficiency, making them ideal for bulk production and beginners in candle making. Choosing between custom and standard molds depends on the balance between creativity, scalability, and budget constraints.

Table of Comparison

| Feature | Custom Molds | Standard Molds |

|---|---|---|

| Design | Unique, tailored shapes and sizes for personalized candles | Pre-made, limited shapes and sizes |

| Cost | Higher initial investment for mold creation | Lower upfront cost and readily available |

| Production Volume | Ideal for small to medium batch runs with specific designs | Suitable for large scale, consistent candle production |

| Lead Time | Longer due to mold design and manufacturing process | Immediate use with no extra production time |

| Flexibility | High flexibility for creative and branded candles | Limited flexibility, fixed designs |

| Material Compatibility | Can be customized for various wax types and additives | Generally compatible with common candle waxes |

| Durability | Varies based on material choice and craftsmanship | Consistent durability across standard designs |

Understanding Candle Mold Types: Custom vs Standard

Custom candle molds offer unique designs tailored to specific shapes, sizes, and intricate details, enhancing brand identity and product differentiation. Standard molds provide consistent dimensions and faster production times, ideal for bulk candle manufacturing with reliable quality. Selecting between custom and standard molds depends on balancing creativity with cost-efficiency and production volume in candle making.

Design Flexibility: Unique Shapes and Branding

Custom molds offer unparalleled design flexibility, allowing candle makers to create unique shapes that reflect specific branding and artistic vision. Unlike standard molds, which limit designs to pre-made forms, custom molds enable intricate details and personalized logos that enhance product differentiation in competitive markets. This tailored approach supports brand identity development and attracts niche customers seeking distinctive, handcrafted candles.

Production Costs: Comparing Custom and Standard Molds

Custom molds typically involve higher initial production costs due to design and tooling expenses but offer long-term savings with unique shapes and brand differentiation. Standard molds have lower upfront costs and faster turnaround times, making them cost-effective for mass production and simple candle designs. Choosing between custom and standard molds depends on balancing budget constraints with desired product customization and market positioning.

Lead Time and Manufacturing Efficiency

Custom molds significantly extend lead time due to design, prototyping, and testing phases, typically adding several weeks compared to standard molds. Standard molds streamline manufacturing efficiency by enabling repetitive use without modification, reducing setup time and improving production speed. Choosing custom molds is ideal for unique candle designs requiring differentiation, whereas standard molds optimize mass production timelines and resource allocation.

Material Choices for Custom and Standard Molds

Custom candle molds often utilize high-quality silicone for its flexibility and heat resistance, enabling intricate designs and easy demolding. Standard candle molds are typically made from durable materials like metal or hard plastic, offering consistent shapes but limited design variation. The choice between silicone custom molds and rigid standard molds significantly impacts candle detail, production speed, and mold lifespan.

Scalability: Small Batch vs Large Scale Production

Custom molds offer unparalleled flexibility for small batch candle making, allowing artisans to experiment with unique designs and intricate details tailored to niche markets. Standard molds enhance scalability in large scale production by streamlining the manufacturing process, reducing cycle times, and ensuring consistency across high volume outputs. Choosing between custom and standard molds depends on balancing creativity with operational efficiency to meet production goals.

Quality Control and Consistency in Candle Making

Custom molds in candle making offer superior quality control by allowing precise adjustment of size, shape, and detail, ensuring each candle meets specific design standards. Standard molds provide consistent outputs suitable for mass production but may lack the nuanced finish achievable with custom molds. Investing in custom molds enhances consistency and quality, especially for artisanal or branded candles requiring unique features and uniformity.

Market Differentiation and Product Appeal

Custom molds in candle making offer unique shapes and intricate designs that enhance market differentiation by attracting niche customer segments seeking personalized products. Standard molds provide consistency and cost efficiency, appealing to mass-market consumers focused on affordability and uniformity. Leveraging custom molds elevates product appeal through exclusive aesthetics, while standard molds support scalability and fast production turnaround.

Maintenance and Longevity of Molds

Custom molds in candle making often require more meticulous maintenance due to their unique shapes and materials, which can affect their longevity if not properly cared for. Standard molds, typically made from durable materials like silicone or metal, offer easier cleaning and consistent heat resistance, extending their lifespan with minimal upkeep. Proper storage and routine inspection for cracks or residue build-up are essential practices to maximize the durability of both custom and standard candle molds.

Choosing the Right Mold for Your Candle Business

Selecting the right mold is crucial for candle making, as custom molds offer unique shapes that can elevate product differentiation and brand identity, while standard molds provide cost-effective solutions with consistent sizes and easy availability. Custom molds require higher upfront investment and longer production times but allow for tailored designs that attract niche markets, whereas standard molds support bulk production and faster turnover. Evaluating your target market, production scale, and budget will help determine whether custom or standard molds best align with your candle business goals.

Custom molds vs Standard molds Infographic

bizdif.com

bizdif.com