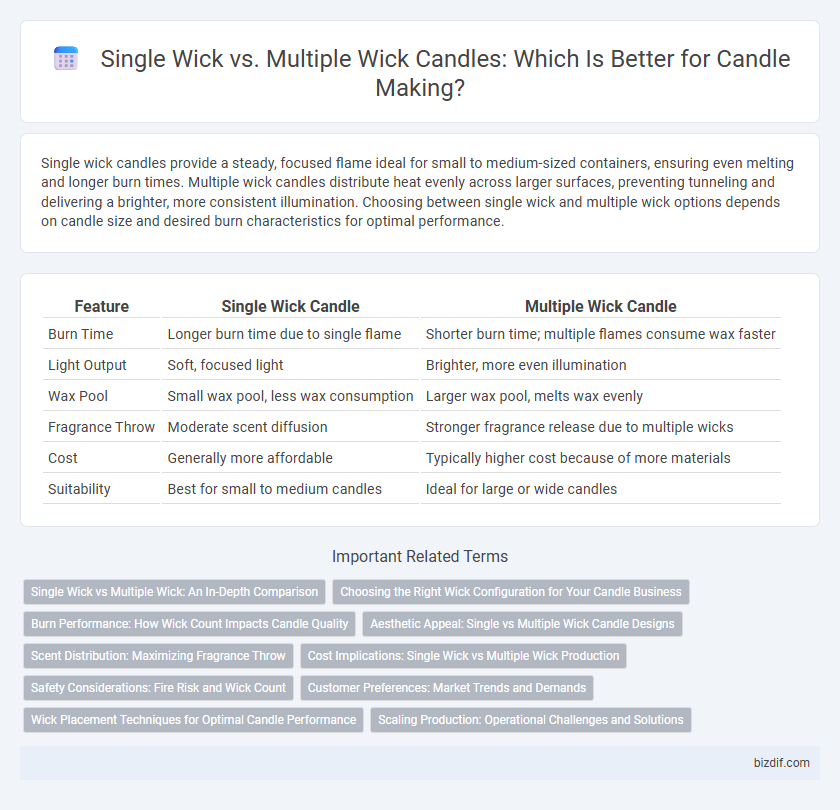

Single wick candles provide a steady, focused flame ideal for small to medium-sized containers, ensuring even melting and longer burn times. Multiple wick candles distribute heat evenly across larger surfaces, preventing tunneling and delivering a brighter, more consistent illumination. Choosing between single wick and multiple wick options depends on candle size and desired burn characteristics for optimal performance.

Table of Comparison

| Feature | Single Wick Candle | Multiple Wick Candle |

|---|---|---|

| Burn Time | Longer burn time due to single flame | Shorter burn time; multiple flames consume wax faster |

| Light Output | Soft, focused light | Brighter, more even illumination |

| Wax Pool | Small wax pool, less wax consumption | Larger wax pool, melts wax evenly |

| Fragrance Throw | Moderate scent diffusion | Stronger fragrance release due to multiple wicks |

| Cost | Generally more affordable | Typically higher cost because of more materials |

| Suitability | Best for small to medium candles | Ideal for large or wide candles |

Single Wick vs Multiple Wick: An In-Depth Comparison

Single wick candles provide a steady, controlled burn ideal for small to medium-sized containers, offering simplicity and longer burn time per ounce of wax. Multiple wick candles create a more intense, even melt pool, reducing tunneling and enhancing fragrance throw in larger or wider vessels. Choosing between single and multiple wicks depends on candle diameter, desired burn characteristics, and optimal scent dispersion.

Choosing the Right Wick Configuration for Your Candle Business

Selecting the right wick configuration is essential for optimizing burn time, fragrance throw, and customer satisfaction in candle making. Single wick candles suit smaller containers and produce a steady, consistent flame, while multiple wick candles are ideal for larger vessels to ensure even melting and better scent distribution. Evaluating container size, wax type, and intended candle use helps candle businesses improve performance and market appeal through effective wick choices.

Burn Performance: How Wick Count Impacts Candle Quality

Single wick candles typically offer a slower, more controlled burn ideal for smaller containers, ensuring a consistent melt pool and minimizing tunneling. Multiple wick candles provide a stronger, more even heat distribution across larger surfaces, preventing uneven burning and wax pooling. Wick count directly influences burn quality by balancing flame size, heat output, and wax consumption for optimal candle performance.

Aesthetic Appeal: Single vs Multiple Wick Candle Designs

Single wick candles offer a classic, minimalist aesthetic that emphasizes simplicity and elegance, making them ideal for smaller spaces or subtle ambiance. Multiple wick candles provide a dynamic visual appeal with evenly distributed flames, creating a dramatic and luxurious centerpiece in larger areas. The choice between single and multiple wick designs significantly influences the mood and style of candle decor.

Scent Distribution: Maximizing Fragrance Throw

Single wick candles typically provide a concentrated scent throw that is ideal for smaller spaces, as the single flame heats the wax evenly, releasing fragrance gradually. Multiple wick candles generate more heat and larger melt pools, maximizing scent distribution across larger areas by dispersing fragrance more rapidly and uniformly. The choice between single and multiple wicks directly impacts the intensity and reach of the candle's fragrance, influencing user experience in various room sizes.

Cost Implications: Single Wick vs Multiple Wick Production

Single wick candles generally incur lower production costs due to minimal wick material and simpler pouring processes, reducing labor and materials. Multiple wick candles require additional wick supplies and more complex molds or containers, increasing both raw materials and manufacturing time. Economies of scale and market pricing should also be considered when evaluating cost effectiveness for single versus multiple wick candle production.

Safety Considerations: Fire Risk and Wick Count

Single wick candles generally present a lower fire risk due to concentrated heat and a smaller flame, reducing the likelihood of accidental ignition. Multiple wick candles, while providing even burning and stronger scent throw, can increase fire hazards as more flames and higher heat output raise the potential for wax splattering and faster container overheating. Proper container choice and regular wick trimming are essential safety measures to manage fire risk regardless of wick count.

Customer Preferences: Market Trends and Demands

Single wick candles dominate consumer preference for their clean, consistent burn and aesthetic simplicity, favored in both home decor and gift markets. Multiple wick candles gain traction in larger spaces, delivering increased fragrance throw and brighter illumination, appealing to customers seeking enhanced ambiance. Market trends indicate rising demand for multi wick options in luxury and artisanal candle segments, driven by increased consumer interest in sensory experience and interior design impact.

Wick Placement Techniques for Optimal Candle Performance

Strategic wick placement significantly impacts candle performance, where single wick candles offer a concentrated flame ideal for smaller containers, ensuring even wax melt and consistent scent release. Multiple wick designs, arranged symmetrically for balanced heat distribution, prevent tunneling in larger or wider candles, enhancing burn efficiency and maximizing fragrance diffusion. Precise spacing of wicks, typically 1 to 1.5 inches apart, is crucial to avoid excessive soot while promoting optimal flame size and stable combustion.

Scaling Production: Operational Challenges and Solutions

Scaling production in candle making with single wicks faces limitations in burn time and fragrance diffusion, leading to slower output and inconsistent quality. Multiple wick candles increase production complexity, requiring precise wick placement and specialized molds to ensure even combustion and prevent tunneling. Implementing automated wick setting machines and quality control protocols can mitigate operational challenges and enhance efficiency in large-scale manufacturing.

Single Wick vs Multiple Wick Infographic

bizdif.com

bizdif.com