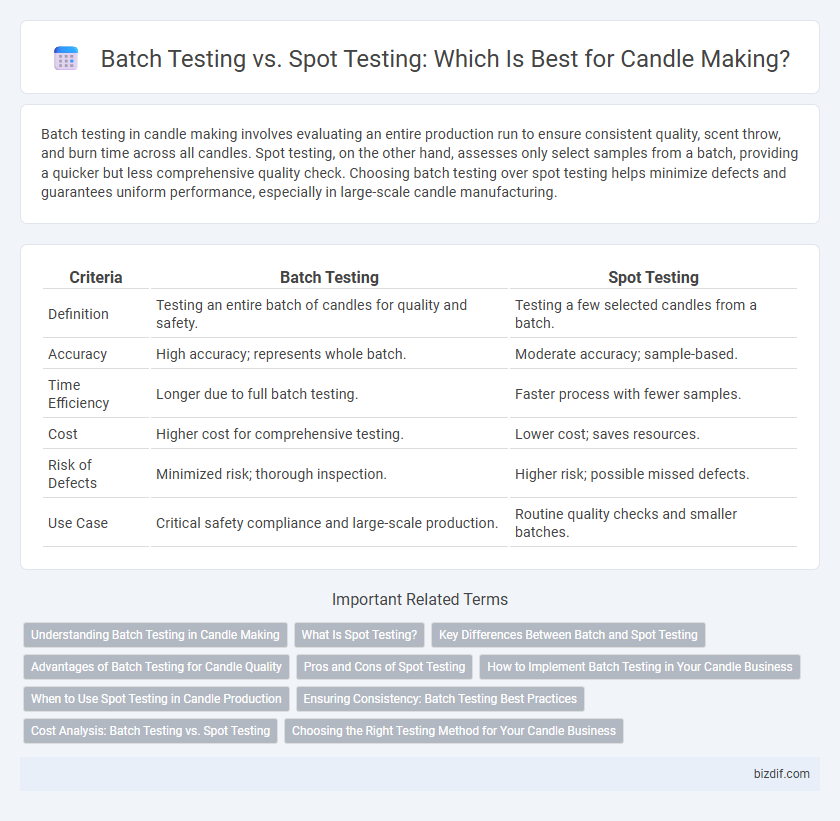

Batch testing in candle making involves evaluating an entire production run to ensure consistent quality, scent throw, and burn time across all candles. Spot testing, on the other hand, assesses only select samples from a batch, providing a quicker but less comprehensive quality check. Choosing batch testing over spot testing helps minimize defects and guarantees uniform performance, especially in large-scale candle manufacturing.

Table of Comparison

| Criteria | Batch Testing | Spot Testing |

|---|---|---|

| Definition | Testing an entire batch of candles for quality and safety. | Testing a few selected candles from a batch. |

| Accuracy | High accuracy; represents whole batch. | Moderate accuracy; sample-based. |

| Time Efficiency | Longer due to full batch testing. | Faster process with fewer samples. |

| Cost | Higher cost for comprehensive testing. | Lower cost; saves resources. |

| Risk of Defects | Minimized risk; thorough inspection. | Higher risk; possible missed defects. |

| Use Case | Critical safety compliance and large-scale production. | Routine quality checks and smaller batches. |

Understanding Batch Testing in Candle Making

Batch testing in candle making involves evaluating a complete production run to ensure uniform quality, fragrance consistency, and burn performance across all candles in the batch. This comprehensive method identifies potential issues related to wax formulation, wick selection, and fragrance load before the products reach consumers. Batch testing provides reliable data for quality control, reducing variability and enhancing product reliability in commercial candle production.

What Is Spot Testing?

Spot testing in candle making involves evaluating a small sample from a single batch to quickly assess fragrance throw, wick performance, and burn quality. This targeted approach helps identify potential issues in scent diffusion, soot production, or wick size without testing the entire batch, saving time and resources. Spot testing is essential for fine-tuning formulas and ensuring consistent candle quality before full-scale production.

Key Differences Between Batch and Spot Testing

Batch testing in candle making involves evaluating a complete production run to ensure consistent quality across all candles, whereas spot testing examines only a small sample from the batch. Batch testing provides comprehensive data on factors like scent throw, burn time, and wax quality, while spot testing offers quicker, less detailed insights predominantly used for immediate quality checks. The key difference lies in the scope and thoroughness, with batch testing ensuring overall batch uniformity and spot testing focusing on faster, targeted quality assessments.

Advantages of Batch Testing for Candle Quality

Batch testing ensures consistent candle quality by evaluating an entire production run, reducing variability and improving reliability. This method identifies defects or inconsistencies across the batch, enhancing safety and performance standards. It also streamlines quality control, minimizing waste and optimizing resource allocation during candle manufacturing.

Pros and Cons of Spot Testing

Spot testing in candle making allows for quick assessment of fragrance throw, color, and burn quality on a smaller scale, saving time and materials compared to batch testing. However, it may not fully represent the consistency or performance of an entire batch, potentially leading to variations in the final product. Spot testing is ideal for initial evaluations, but larger batch tests provide more reliable data for production consistency.

How to Implement Batch Testing in Your Candle Business

Implement batch testing in your candle business by producing a specific number of candles under identical conditions and evaluating key quality factors such as burn time, scent throw, and wick performance across the entire batch. Carefully document variations and batch-specific results to identify consistency and uncover any formulation or process issues. Employ standardized testing protocols and maintain detailed production logs to ensure reproducibility and continuous product improvement.

When to Use Spot Testing in Candle Production

Spot testing in candle production is essential when assessing specific qualities such as fragrance throw or wick performance in limited samples before committing to large batches. It is ideal for quick evaluations during formula adjustments or ingredient substitutions to ensure consistent product quality. Spot testing helps identify potential issues early, reducing waste and optimizing production efficiency.

Ensuring Consistency: Batch Testing Best Practices

Batch testing in candle making ensures consistent fragrance, color, and burn quality by evaluating entire production batches rather than isolated samples. This method identifies variations in wax composition, wick placement, and curing time, enhancing overall product reliability. Implementing standardized protocols and detailed record-keeping during batch testing optimizes quality control and customer satisfaction.

Cost Analysis: Batch Testing vs. Spot Testing

Batch testing in candle making involves evaluating an entire production batch, leading to higher upfront costs but reducing the risk of widespread defects and costly returns. Spot testing, on the other hand, targets random samples, lowering initial expenses but increasing the possibility of undetected quality issues that may result in greater long-term costs. Efficient cost analysis balances the expense of comprehensive batch testing against the risk and potential financial impact associated with spot testing's limited scope.

Choosing the Right Testing Method for Your Candle Business

Batch testing ensures consistent fragrance load and burn quality by analyzing entire production batches, making it ideal for businesses prioritizing uniformity and customer satisfaction. Spot testing evaluates individual candles, offering speedy feedback for small-scale or custom orders where variation is expected. Selecting the right method depends on production volume, desired quality control rigor, and the need for efficiency in your candle making business.

Batch testing vs Spot testing Infographic

bizdif.com

bizdif.com