Traditional molds for candle making offer a classic craftsmanship feel and are often made from durable materials like metal or silicone, providing consistent shapes and smooth finishes. 3D printed molds enable intricate, customizable designs with rapid prototyping, allowing for unique, detailed candle patterns that are difficult to achieve by traditional means. While traditional molds excel in replicability and durability, 3D printed molds push creative boundaries and reduce production time for bespoke candle projects.

Table of Comparison

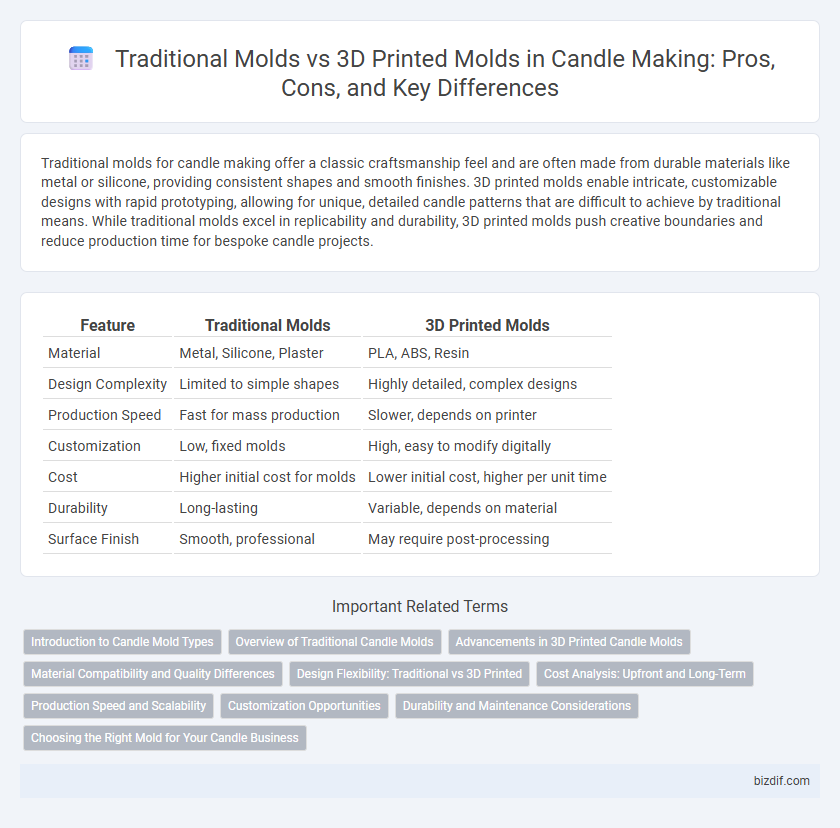

| Feature | Traditional Molds | 3D Printed Molds |

|---|---|---|

| Material | Metal, Silicone, Plaster | PLA, ABS, Resin |

| Design Complexity | Limited to simple shapes | Highly detailed, complex designs |

| Production Speed | Fast for mass production | Slower, depends on printer |

| Customization | Low, fixed molds | High, easy to modify digitally |

| Cost | Higher initial cost for molds | Lower initial cost, higher per unit time |

| Durability | Long-lasting | Variable, depends on material |

| Surface Finish | Smooth, professional | May require post-processing |

Introduction to Candle Mold Types

Traditional candle molds, typically made from metal or silicone, provide durability and reuse, producing consistent shapes for classic candle designs. 3D printed molds offer customization and intricate detail, enabling unique and complex candle forms not possible with conventional molds. The choice between traditional and 3D printed molds depends on production needs, design complexity, and desired finish quality.

Overview of Traditional Candle Molds

Traditional candle molds are typically made from materials such as metal, silicone, or plaster, known for their durability and ability to produce detailed shapes. These molds rely on established techniques that enable consistent cooling and solidification, which are essential for maintaining the candle's structure and surface texture. The craftsmanship involved in traditional molds often results in unique, artisanal candles valued for their classic appearance and handmade quality.

Advancements in 3D Printed Candle Molds

3D printed candle molds offer unprecedented precision and customization compared to traditional molds, enabling intricate designs and rapid prototyping that enhance creative possibilities in candle making. Advanced 3D printing materials provide flexibility, durability, and heat resistance, ensuring molds withstand wax temperatures without deformation or damage. This technology reduces production time and costs while allowing for easy adjustments to mold complexity, making it ideal for both artisanal and commercial candle manufacturers.

Material Compatibility and Quality Differences

Traditional molds for candle making are typically crafted from silicone or metal, offering excellent heat resistance and durability, ensuring consistent candle shapes and smooth surfaces. In contrast, 3D printed molds made from PLA or resin provide customizable designs but may have limitations in heat tolerance and surface finish, potentially resulting in minor imperfections or shorter lifespan. Material compatibility with different wax types, such as soy or paraffin, often favors traditional molds for optimal quality and longevity in candle production.

Design Flexibility: Traditional vs 3D Printed

Traditional molds offer limited design flexibility, often restricted to basic shapes and patterns due to manufacturing constraints. 3D printed molds enable intricate, custom designs with high precision and complexity, allowing candle makers to experiment with unique textures and detailed features. This advanced flexibility accelerates prototyping and personalized production, transforming creative possibilities in candle making.

Cost Analysis: Upfront and Long-Term

Traditional candle molds require lower initial investment costs, often made from affordable materials like aluminum or silicone, making them accessible for small-scale producers. In contrast, 3D printed molds involve higher upfront expenses due to equipment and design software but offer significant long-term savings through customization, rapid prototyping, and reduced material waste. Over time, 3D printing can lower production costs for complex or small-batch candles by minimizing labor and enabling on-demand manufacturing.

Production Speed and Scalability

Traditional candle molds, typically made from metal or silicone, offer consistent shapes but require longer cooling times, limiting production speed. In contrast, 3D printed molds enable rapid prototyping and customization while supporting faster iteration cycles, enhancing scalability for mass production. The ability of 3D printing to quickly adjust mold designs reduces downtime and increases overall manufacturing efficiency in candle making.

Customization Opportunities

Traditional molds offer limited customization, often restricted to standard shapes and sizes, which can constrain creativity in candle making. 3D printed molds enable intricate, highly personalized designs, allowing artisans to experiment with unique shapes, textures, and complex patterns that are difficult to achieve with conventional methods. This advanced level of customization enhances product differentiation and meets specific customer preferences effectively.

Durability and Maintenance Considerations

Traditional candle molds, typically made from metals like aluminum or steel, offer exceptional durability and withstand repeated heat exposure without deforming, making them ideal for long-term use. In contrast, 3D printed molds, often produced from PLA or resin materials, can degrade faster under high temperatures and may require more frequent replacement or careful temperature control during candle making. Maintenance for traditional molds involves simple cleaning and occasional polishing to prevent rust, whereas 3D printed molds demand delicate handling to avoid surface damage and may need specialized cleaning techniques to preserve mold integrity.

Choosing the Right Mold for Your Candle Business

When choosing the right mold for your candle business, consider that traditional molds offer proven durability and classic designs ideal for bulk production, while 3D printed molds provide customizable shapes and intricate details tailored to niche markets. Traditional molds typically use materials like silicone or metal, ensuring long-lasting use and consistent results, whereas 3D printed molds allow rapid prototyping and faster adaptation to design trends. Evaluating factors such as production volume, design complexity, and cost efficiency will help determine whether traditional or 3D printed molds best align with your candle business goals.

Traditional molds vs 3D printed molds Infographic

bizdif.com

bizdif.com