Selecting the appropriate wick size is crucial for achieving an even burn and preventing tunneling in candle making. Wick material influences the flame's stability and burn rate, with options like cotton, wood, or hemp offering different burn characteristics and aesthetic effects. Properly balancing wick size and material ensures optimal combustion, scent throw, and safety in handmade candles.

Table of Comparison

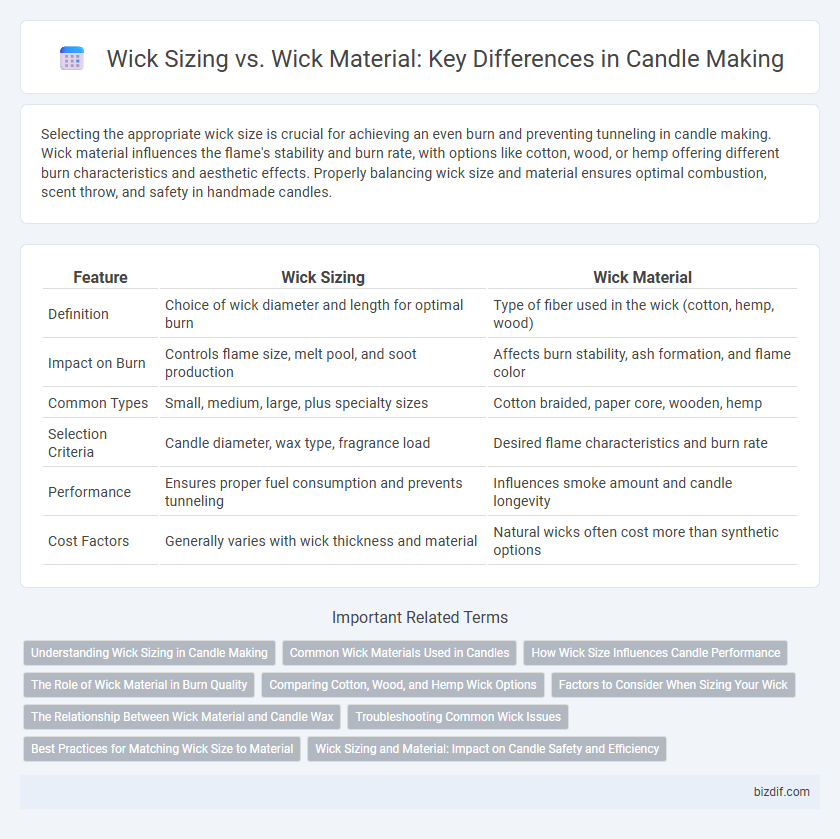

| Feature | Wick Sizing | Wick Material |

|---|---|---|

| Definition | Choice of wick diameter and length for optimal burn | Type of fiber used in the wick (cotton, hemp, wood) |

| Impact on Burn | Controls flame size, melt pool, and soot production | Affects burn stability, ash formation, and flame color |

| Common Types | Small, medium, large, plus specialty sizes | Cotton braided, paper core, wooden, hemp |

| Selection Criteria | Candle diameter, wax type, fragrance load | Desired flame characteristics and burn rate |

| Performance | Ensures proper fuel consumption and prevents tunneling | Influences smoke amount and candle longevity |

| Cost Factors | Generally varies with wick thickness and material | Natural wicks often cost more than synthetic options |

Understanding Wick Sizing in Candle Making

Wick sizing in candle making is crucial to ensure proper flame size and combustion, as an incorrectly sized wick can cause poor candle performance or safety hazards. Wick material, such as cotton, wood, or hemp, influences burn rate and flame stability, but selecting the right wick size is essential to balance fuel delivery and oxygen supply. Proper wick sizing depends on candle diameter, wax type, and fragrance load, making it vital to test different sizes for optimal burn quality.

Common Wick Materials Used in Candles

Common wick materials used in candles include cotton, wood, hemp, and paper-core, each affecting the wick sizing and burning performance differently. Cotton wicks are popular for their clean burn and flexibility in sizing, while wood wicks provide a distinctive crackling sound but require precise sizing to prevent tunneling. Selection of wick material directly influences the candle's flame stability, scent throw, and overall burn time, making proper wick sizing crucial for achieving optimal candle performance.

How Wick Size Influences Candle Performance

Wick size directly impacts candle performance by controlling the flame height, melt pool depth, and overall burn efficiency, ensuring optimal wax consumption and scent throw. Choosing the correct wick size prevents issues like excessive soot production, tunneling, or uneven burning, which can degrade candle quality and safety. The wick material must complement the wick size to maintain a stable flame and consistent burn time tailored to the candle's diameter and wax type.

The Role of Wick Material in Burn Quality

Wick material plays a crucial role in burn quality by influencing the rate of wax consumption and the consistency of the flame, with common materials including cotton, wood, and hemp, each offering distinct burning characteristics. Proper wick sizing depends on the wick material's absorption capacity and rigidity, where a thicker or denser material requires adjustments to prevent larger flames or soot production. Selecting suitable wick material optimizes combustion efficiency, reduces tunneling, and enhances the overall scent throw and candle lifespan.

Comparing Cotton, Wood, and Hemp Wick Options

Cotton wicks offer consistent burn and easy trimming, ideal for most candle types, while wood wicks provide a unique crackling sound and a wide flame but require precise sizing to prevent tunneling or excessive smoke. Hemp wicks, known for their durability and natural carbonization, burn longer and are excellent for beeswax candles but may need careful trimming to avoid uneven burning. Selecting the right wick size depends on the candle diameter and wax type, with cotton generally forgiving in sizing, wood wicks requiring exact measurement, and hemp wicks benefiting from slightly larger sizes to maintain optimal flame stability.

Factors to Consider When Sizing Your Wick

Choosing the right wick size depends primarily on the wax type, candle diameter, and fragrance load to ensure an optimal burn. Wick material, such as cotton, wood, or hemp, influences heat distribution and burn rate, affecting how the wick size interacts with the candle's composition. Correctly matching wick size to material and candle characteristics prevents issues like tunneling, excessive soot, or incomplete combustion, enhancing the candle's performance and safety.

The Relationship Between Wick Material and Candle Wax

Wick material significantly influences the burning characteristics and efficiency of a candle wick, directly impacting the optimal wick size needed for different wax types such as soy, beeswax, or paraffin. Natural cotton wicks absorb wax differently than wood or hemp wicks, affecting flame size, burn rate, and soot production, which must be matched precisely to the wax's melt point and viscosity for a clean, consistent burn. Selecting the correct wick material tailored to the wax formulation ensures balanced heat distribution, minimizing tunneling and maximizing scent throw.

Troubleshooting Common Wick Issues

Selecting the correct wick size relative to the wick material is crucial for optimal candle performance, as an undersized wick can cause tunneling or weak flames, while an oversized wick may produce excessive smoke or soot. Cotton wicks generally require a moderate diameter to ensure steady combustion, whereas wooden wicks often need a wider gauge to maintain a consistent burn and avoid extinguishing prematurely. Troubleshooting common wick issues involves adjusting the wick size or switching wick materials to balance flame height, prevent flickering, and achieve even wax melt pools.

Best Practices for Matching Wick Size to Material

Selecting the correct wick size based on wick material is crucial for optimal candle performance, as thicker cotton or wooden wicks require specific diameters to ensure consistent burning and prevent tunneling. Cotton wicks need to be matched to the candle's wax type and fragrance load, with larger wicks for soy wax due to its density, while wooden wicks often demand broader sizing to maintain a steady flame. Testing various wick sizes within the same material category helps identify the best match, ensuring clean combustion and maximizing fragrance throw for high-quality candles.

Wick Sizing and Material: Impact on Candle Safety and Efficiency

Selecting the appropriate wick size and material is crucial for candle safety and burning efficiency, as an undersized wick can cause tunneling and excessive soot, while an oversized wick increases the risk of a large, uncontrollable flame. Cotton, wood, and hemp are common wick materials, each influencing the burn rate and scent throw due to their distinct combustion properties. Properly matched wick size and material ensure even melting of wax, reduce the likelihood of carbon buildup, and optimize the candle's overall performance.

Wick sizing vs Wick material Infographic

bizdif.com

bizdif.com