Tunneling in candle making occurs when a narrow, deep burn channel forms, reducing the candle's overall wax consumption and scent throw. Achieving a full melt pool ensures the entire surface melts evenly, maximizing fragrance release and preventing wasted wax along the edges. Proper wick size and wax type are crucial to avoid tunneling and maintain an efficient, consistent burn.

Table of Comparison

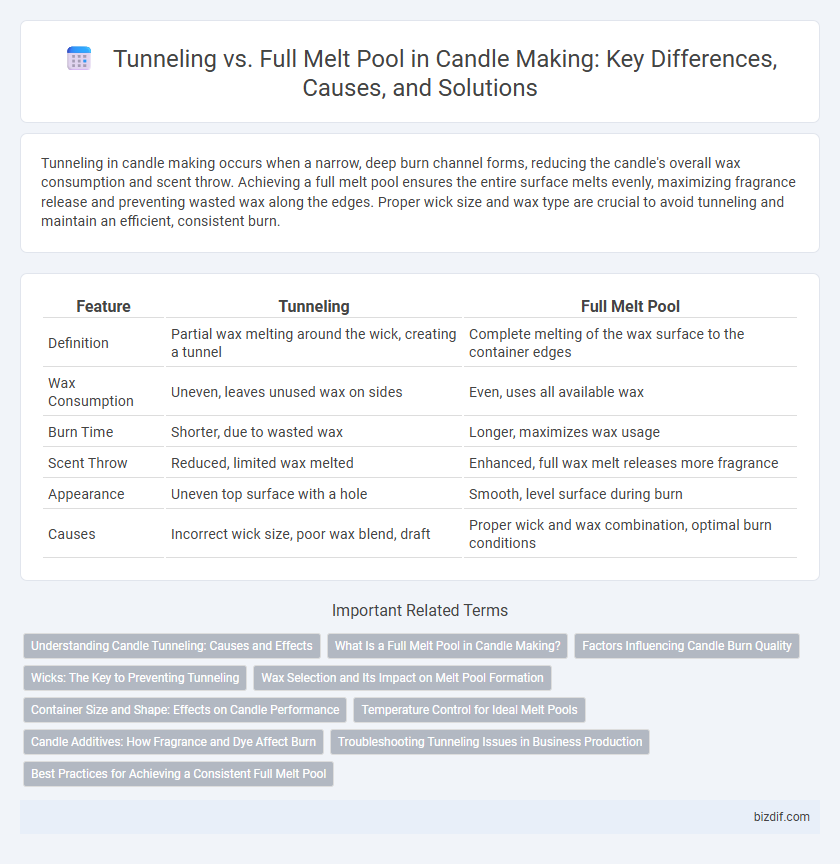

| Feature | Tunneling | Full Melt Pool |

|---|---|---|

| Definition | Partial wax melting around the wick, creating a tunnel | Complete melting of the wax surface to the container edges |

| Wax Consumption | Uneven, leaves unused wax on sides | Even, uses all available wax |

| Burn Time | Shorter, due to wasted wax | Longer, maximizes wax usage |

| Scent Throw | Reduced, limited wax melted | Enhanced, full wax melt releases more fragrance |

| Appearance | Uneven top surface with a hole | Smooth, level surface during burn |

| Causes | Incorrect wick size, poor wax blend, draft | Proper wick and wax combination, optimal burn conditions |

Understanding Candle Tunneling: Causes and Effects

Candle tunneling occurs when only the center of the wax melts during burning, leaving unmelted wax around the edges that wastes material and shortens burn time. Causes include using a wick that is too small, improper wax type, or inadequate initial burn time to establish a full melt pool. Understanding these factors is essential to preventing tunneling and achieving a full melt pool, which ensures even burning, optimal scent throw, and maximum candle lifespan.

What Is a Full Melt Pool in Candle Making?

A full melt pool in candle making occurs when the entire surface of the wax melts evenly, allowing the candle to burn cleanly and release its scent effectively. Unlike tunneling, where only a narrow channel melts around the wick, a full melt pool maximizes fragrance throw and prevents wax waste by ensuring complete surface liquefaction. Achieving a full melt pool depends on factors such as wick size, wax type, and container dimensions.

Factors Influencing Candle Burn Quality

Candle burn quality is significantly influenced by achieving a full melt pool rather than experiencing tunneling, which occurs when only the wax around the wick melts. Factors such as wick size, wax type, fragrance load, and container diameter directly affect melt pool formation and ensure an even burn. Proper wick trimming and optimal room temperature also contribute to preventing tunneling and promoting consistent, clean burn performance.

Wicks: The Key to Preventing Tunneling

Wicks play a crucial role in preventing tunneling by ensuring an even and full melt pool across the candle surface. Selecting the appropriate wick size and material optimizes heat distribution, promoting consistent wax melting and eliminating wasted wax around the edges. Proper wick maintenance and trimming further support a steady flame, reducing the risk of tunneling and enhancing overall candle performance.

Wax Selection and Its Impact on Melt Pool Formation

Choosing the right wax blend is crucial for controlling melt pool behavior in candle making, as different wax types like soy, paraffin, or beeswax have distinct melting points and viscosities. Soy wax, for example, often creates a full melt pool due to its lower melting point and slower solidification, promoting even burn and scent throw. In contrast, paraffin wax tends to tunnel if the formulation or wick size is incorrect, as it melts unevenly, which underscores the importance of matching wax properties with wick and fragrance load for optimal melt pool development.

Container Size and Shape: Effects on Candle Performance

Container size and shape significantly influence candle performance by impacting tunneling and full melt pool formation. Larger, wider containers promote full melt pools by allowing the wax to melt evenly across the surface, preventing tunneling where only the center melts. Conversely, narrow or tall containers often restrict heat distribution, increasing the risk of tunneling and reducing burn time efficiency.

Temperature Control for Ideal Melt Pools

Achieving an ideal melt pool in candle making relies heavily on precise temperature control to prevent tunneling and ensure a full melt pool. Maintaining wax at the optimal pouring temperature, typically between 130degF and 150degF, promotes even melting and consistent burning. Monitoring wick size and candle diameter alongside wax temperature stabilizes combustion, minimizing tunneling and maximizing melt pool coverage.

Candle Additives: How Fragrance and Dye Affect Burn

Fragrance oils and dyes in candle additives significantly influence the burn characteristics by affecting the melt pool's size and consistency, with improper ratios leading to tunneling or incomplete melting. Fragrance load above 10% can hinder wick performance, causing uneven combustion and smaller melt pools, while excessive dye concentration can thicken wax, limiting heat transfer and promoting tunneling. Optimizing additive levels ensures a full melt pool, enhancing scent throw and creating a cleaner, more efficient burn.

Troubleshooting Tunneling Issues in Business Production

Tunneling in candle making occurs when the wick burns down the center too quickly, leaving unmelted wax around the edges, which reduces the candle's overall burn time and waste product. Troubleshooting tunneling issues involves selecting the correct wick size, adjusting fragrance load, and ensuring an even pour temperature and container size to promote a full melt pool that reaches the candle's edges each burn. Consistently achieving a full melt pool enhances customer satisfaction by delivering optimal fragrance throw and longer-lasting candles in business production.

Best Practices for Achieving a Consistent Full Melt Pool

Achieving a consistent full melt pool in candle making requires maintaining an appropriate wick size to ensure even heat distribution, preventing tunneling where wax melts unevenly and leaves unmelted wax along the container walls. Using high-quality, properly blended wax formulations and controlling the pouring temperature can enhance the wax's melting behavior and wick performance. Monitoring burn times and trimming the wick regularly promotes an optimal burn pool size, ensuring complete wax consumption and maximizing fragrance throw.

Tunneling vs Full melt pool Infographic

bizdif.com

bizdif.com