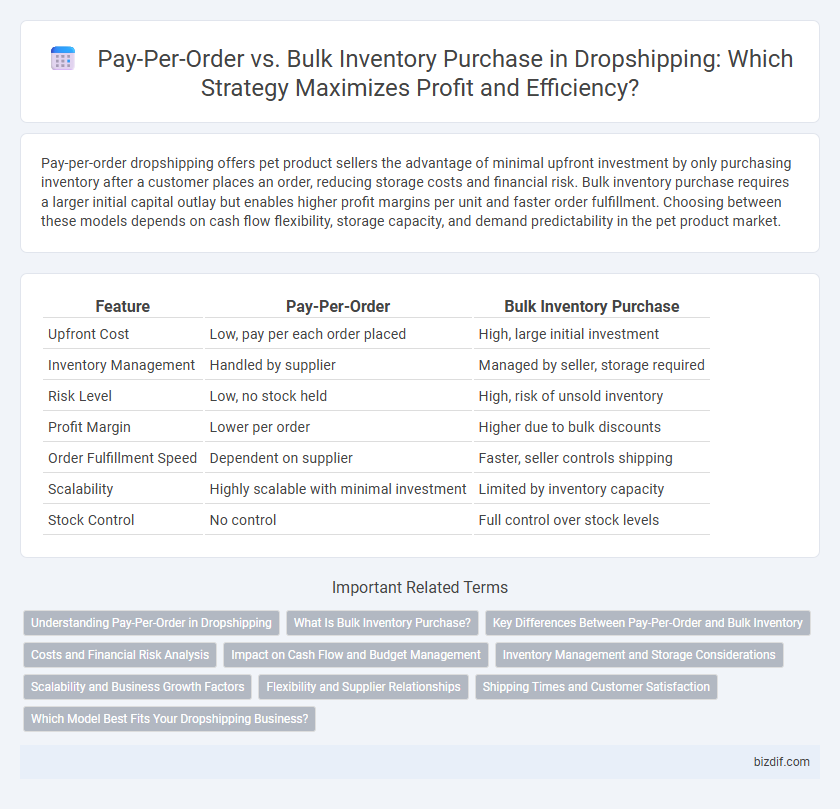

Pay-per-order dropshipping offers pet product sellers the advantage of minimal upfront investment by only purchasing inventory after a customer places an order, reducing storage costs and financial risk. Bulk inventory purchase requires a larger initial capital outlay but enables higher profit margins per unit and faster order fulfillment. Choosing between these models depends on cash flow flexibility, storage capacity, and demand predictability in the pet product market.

Table of Comparison

| Feature | Pay-Per-Order | Bulk Inventory Purchase |

|---|---|---|

| Upfront Cost | Low, pay per each order placed | High, large initial investment |

| Inventory Management | Handled by supplier | Managed by seller, storage required |

| Risk Level | Low, no stock held | High, risk of unsold inventory |

| Profit Margin | Lower per order | Higher due to bulk discounts |

| Order Fulfillment Speed | Dependent on supplier | Faster, seller controls shipping |

| Scalability | Highly scalable with minimal investment | Limited by inventory capacity |

| Stock Control | No control | Full control over stock levels |

Understanding Pay-Per-Order in Dropshipping

Pay-Per-Order in dropshipping allows sellers to list products without upfront inventory costs, paying suppliers only after a customer places an order. This model minimizes financial risk and eliminates the need for warehousing, making it ideal for entrepreneurs with limited capital. Key advantages include flexible product offerings and streamlined order management, supporting scalability in competitive e-commerce markets.

What Is Bulk Inventory Purchase?

Bulk inventory purchase involves buying large quantities of products upfront from suppliers to store and manage inventory independently. This method contrasts with pay-per-order models by requiring significant capital investment and warehouse space but allows for greater control over stock levels and potentially higher profit margins. Businesses using bulk purchasing must efficiently forecast demand and handle logistics to avoid overstock or stockouts.

Key Differences Between Pay-Per-Order and Bulk Inventory

Pay-per-order dropshipping enables sellers to fulfill customer orders without holding inventory, reducing upfront costs and minimizing financial risk. Bulk inventory purchase requires investing in large quantities of stock, which can lead to higher profit margins but increased storage and potential unsold inventory risks. The key differences lie in the capital investment, inventory management responsibilities, and scalability flexibility for online retailers.

Costs and Financial Risk Analysis

Pay-Per-Order dropshipping minimizes upfront costs by eliminating the need to purchase bulk inventory, reducing financial risk associated with unsold stock. Bulk inventory purchase requires significant initial capital investment and carries the potential for losses tied to excess or obsolete products but offers lower per-unit costs and higher profit margins. Evaluating cash flow constraints and demand predictability is crucial in deciding between flexible, low-risk Pay-Per-Order models and higher-risk, bulk inventory strategies.

Impact on Cash Flow and Budget Management

Pay-Per-Order dropshipping minimizes upfront investment, improving cash flow by only paying for products after customer orders are received, which reduces inventory holding costs and the risk of unsold stock. Bulk inventory purchase demands significant initial capital outlay, potentially straining budget management but enables higher profit margins through supplier discounts and faster order fulfillment. Carefully balancing these models directly influences financial flexibility and operational sustainability in e-commerce businesses.

Inventory Management and Storage Considerations

Pay-per-order dropshipping eliminates the need for inventory storage by shipping products directly from suppliers, reducing warehousing costs and minimizing inventory risks. Bulk inventory purchase requires managing stock levels, storage space, and inventory turnover, increasing overhead expenses and the potential for unsold products. Efficient inventory management in bulk purchasing demands accurate demand forecasting and optimized storage solutions to prevent stockouts or overstock.

Scalability and Business Growth Factors

Pay-Per-Order dropshipping offers high scalability by eliminating upfront inventory costs and minimizing financial risk, allowing businesses to quickly test new product lines and expand their offerings without significant capital investment. Bulk inventory purchase can lead to higher profit margins per unit but requires substantial initial investment and storage capacity, which may limit rapid growth and increase operational complexities for scaling. Choosing between pay-per-order and bulk inventory depends on cash flow flexibility, market demand predictability, and long-term growth strategies in the e-commerce landscape.

Flexibility and Supplier Relationships

Pay-Per-Order dropshipping offers unparalleled flexibility by eliminating upfront inventory costs and allowing sellers to test multiple products without long-term commitments, fostering dynamic supplier relationships through real-time order processing. In contrast, bulk inventory purchases demand significant capital investment and carry risks of unsold stock but can strengthen supplier ties via negotiated discounts and consistent order volumes. Choosing between the two hinges on balancing operational agility with supplier collaboration priorities in the e-commerce supply chain.

Shipping Times and Customer Satisfaction

Pay-Per-Order dropshipping significantly reduces shipping times by sending products directly from suppliers to customers, enhancing overall customer satisfaction with faster delivery compared to bulk inventory purchases that rely on stored stock and often involve slower fulfillment processes. Bulk inventory purchase allows for immediate order processing but risks delays if stock levels fluctuate or require restocking, potentially lowering satisfaction. Optimizing shipping strategies in dropshipping directly impacts customer retention through timely deliveries and reliable order fulfillment.

Which Model Best Fits Your Dropshipping Business?

Pay-Per-Order dropshipping minimizes upfront costs by shipping products directly from suppliers only after a customer places an order, ideal for startups or low-risk inventory management. Bulk Inventory Purchase requires investing in stock upfront, offering higher profit margins and faster shipping but increasing financial risk and storage needs. Assessing your business scale, cash flow, and ability to manage inventory dictates whether a Pay-Per-Order or Bulk Inventory model best fits your dropshipping strategy.

Pay-Per-Order vs Bulk Inventory Purchase Infographic

bizdif.com

bizdif.com