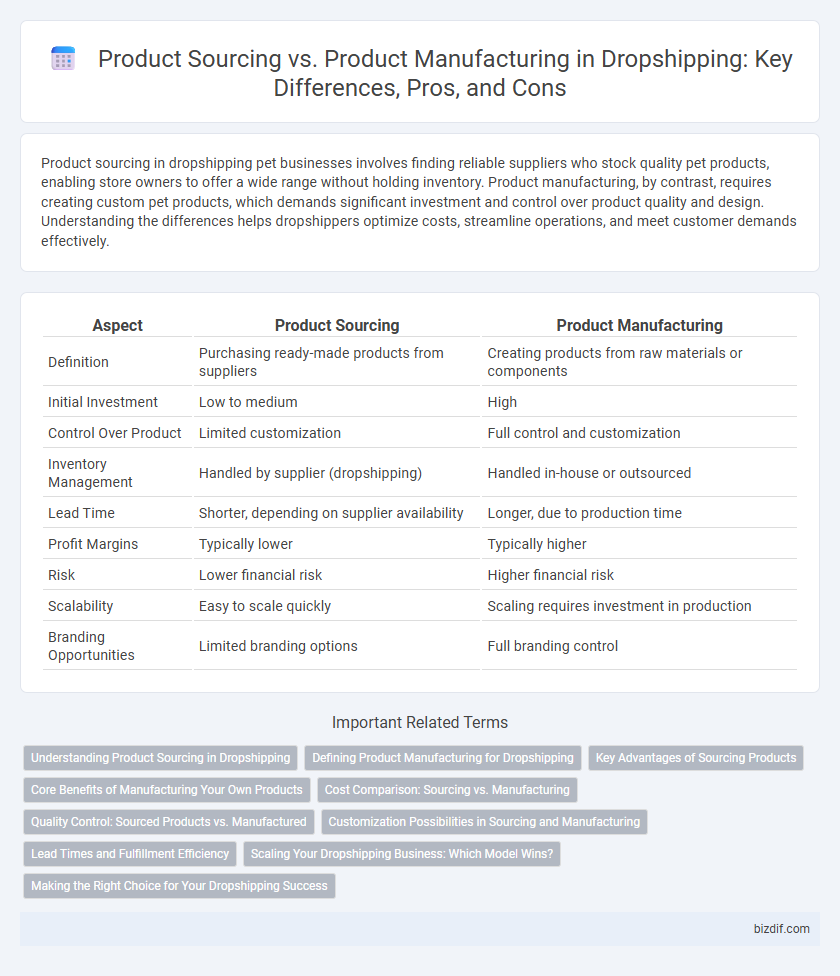

Product sourcing in dropshipping pet businesses involves finding reliable suppliers who stock quality pet products, enabling store owners to offer a wide range without holding inventory. Product manufacturing, by contrast, requires creating custom pet products, which demands significant investment and control over product quality and design. Understanding the differences helps dropshippers optimize costs, streamline operations, and meet customer demands effectively.

Table of Comparison

| Aspect | Product Sourcing | Product Manufacturing |

|---|---|---|

| Definition | Purchasing ready-made products from suppliers | Creating products from raw materials or components |

| Initial Investment | Low to medium | High |

| Control Over Product | Limited customization | Full control and customization |

| Inventory Management | Handled by supplier (dropshipping) | Handled in-house or outsourced |

| Lead Time | Shorter, depending on supplier availability | Longer, due to production time |

| Profit Margins | Typically lower | Typically higher |

| Risk | Lower financial risk | Higher financial risk |

| Scalability | Easy to scale quickly | Scaling requires investment in production |

| Branding Opportunities | Limited branding options | Full branding control |

Understanding Product Sourcing in Dropshipping

Product sourcing in dropshipping involves finding reliable suppliers who stock products and handle inventory and shipping directly, eliminating the need for upfront investment or holding stock. Unlike product manufacturing, where businesses create goods from raw materials, dropshipping relies on third-party vendors to provide a wide range of ready-made items, allowing sellers to offer diverse products without production risks. Effective product sourcing focuses on vetting suppliers for quality, shipping times, and pricing to ensure customer satisfaction and operational efficiency.

Defining Product Manufacturing for Dropshipping

Product manufacturing in dropshipping refers to the process where products are created, assembled, or customized by a supplier or manufacturer before being shipped directly to customers. This approach emphasizes partnering with manufacturers who produce goods on demand, enabling dropshippers to offer unique or branded products without holding inventory. Understanding the distinctions between manufacturing and sourcing helps dropshippers optimize their supply chain management and scale their businesses efficiently.

Key Advantages of Sourcing Products

Product sourcing in dropshipping offers key advantages such as reduced upfront investment and minimized inventory risks compared to product manufacturing. It enables access to a wide range of products without the need for production facilities, allowing faster market entry and scalability. Leveraging established suppliers also ensures streamlined logistics and quality control, enhancing customer satisfaction.

Core Benefits of Manufacturing Your Own Products

Manufacturing your own products offers complete control over quality, allowing for consistent standards and customization options that enhance brand identity. It reduces dependency on third-party suppliers, minimizing delays and supply chain disruptions common in dropshipping models. Owning the production process also enables higher profit margins through cost efficiencies and direct raw material sourcing.

Cost Comparison: Sourcing vs. Manufacturing

Product sourcing in dropshipping typically involves lower upfront costs since it eliminates the need for inventory investment and production expenses, allowing sellers to pay only for items sold. In contrast, product manufacturing demands higher initial capital for raw materials, equipment, labor, and quality control, which increases overall costs but may reduce per-unit expenses in bulk production. Evaluating cost comparison highlights that sourcing offers greater flexibility and reduced financial risk, whereas manufacturing provides potential for higher profit margins through direct control over production processes.

Quality Control: Sourced Products vs. Manufactured

Dropshipping relies heavily on product sourcing, which can lead to variable quality control due to reliance on third-party suppliers with differing standards. In contrast, product manufacturing allows for direct oversight and implementation of strict quality control measures, ensuring consistent product quality. Businesses focusing on quality often prefer manufacturing to mitigate risks associated with defects and customer dissatisfaction common in sourced products.

Customization Possibilities in Sourcing and Manufacturing

Product sourcing in dropshipping offers limited customization options, primarily relying on existing supplier catalogs with minimal adjustments like packaging or branding. Product manufacturing provides extensive customization possibilities, allowing businesses to design unique products tailored to specific customer preferences and market demands. Control over materials, features, and design in manufacturing enhances brand differentiation and customer satisfaction compared to the constraints of sourcing.

Lead Times and Fulfillment Efficiency

Product sourcing in dropshipping offers shorter lead times as products are typically stocked and shipped directly from suppliers, enabling faster fulfillment and reduced inventory management. In contrast, product manufacturing involves longer lead times due to production schedules, raw material procurement, and quality control processes, which can delay order fulfillment. Efficient dropshipping relies on agile suppliers to minimize delays, whereas manufacturing requires robust planning to optimize production cycles and maintain fulfillment speed.

Scaling Your Dropshipping Business: Which Model Wins?

Product sourcing in dropshipping offers scalability through minimal upfront investment and extensive product variety, enabling rapid market testing without inventory risks. Manufacturing, while demanding higher initial capital and longer lead times, allows for unique branding and greater control over product quality, which can drive customer loyalty and higher profit margins. For scaling a dropshipping business, product sourcing wins in agility and speed-to-market, whereas manufacturing supports long-term brand differentiation and sustainable growth.

Making the Right Choice for Your Dropshipping Success

Choosing between product sourcing and product manufacturing is crucial for dropshipping success, as sourcing often allows faster market entry with lower upfront costs, while manufacturing offers greater control over quality and branding. Dropshipping primarily benefits from reliable suppliers who provide ready-made products, minimizing inventory risks and enabling focus on marketing and customer service. Evaluating factors like product niche, scalability, and profit margins helps determine whether sourcing existing products or investing in custom manufacturing aligns better with your business strategy.

Product Sourcing vs Product Manufacturing Infographic

bizdif.com

bizdif.com