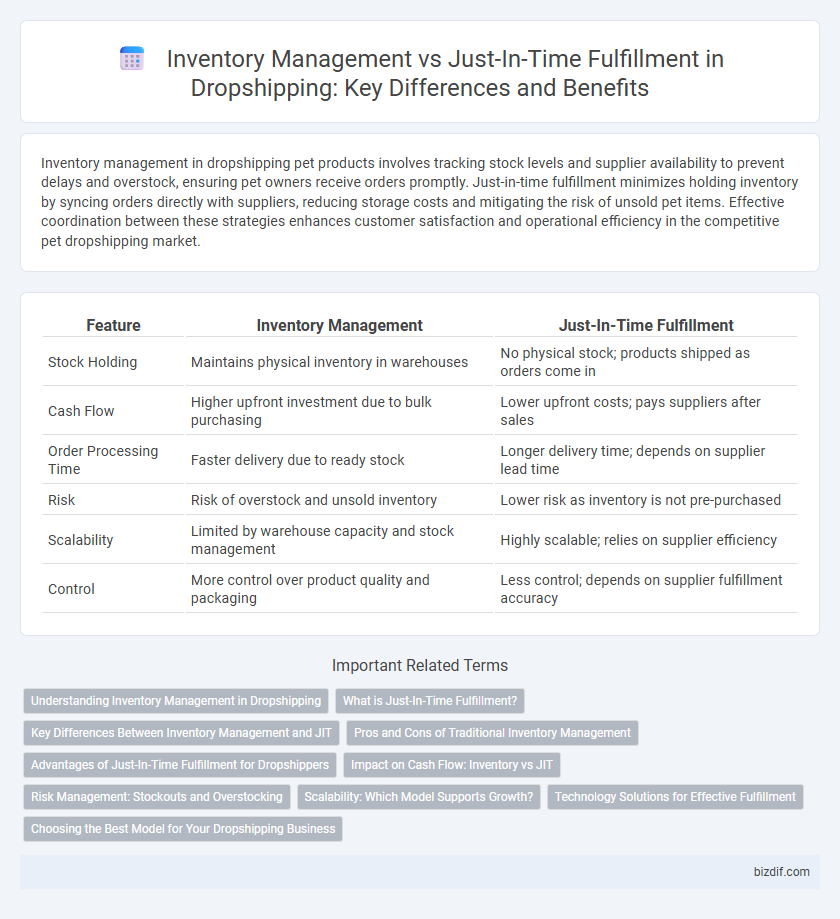

Inventory management in dropshipping pet products involves tracking stock levels and supplier availability to prevent delays and overstock, ensuring pet owners receive orders promptly. Just-in-time fulfillment minimizes holding inventory by syncing orders directly with suppliers, reducing storage costs and mitigating the risk of unsold pet items. Effective coordination between these strategies enhances customer satisfaction and operational efficiency in the competitive pet dropshipping market.

Table of Comparison

| Feature | Inventory Management | Just-In-Time Fulfillment |

|---|---|---|

| Stock Holding | Maintains physical inventory in warehouses | No physical stock; products shipped as orders come in |

| Cash Flow | Higher upfront investment due to bulk purchasing | Lower upfront costs; pays suppliers after sales |

| Order Processing Time | Faster delivery due to ready stock | Longer delivery time; depends on supplier lead time |

| Risk | Risk of overstock and unsold inventory | Lower risk as inventory is not pre-purchased |

| Scalability | Limited by warehouse capacity and stock management | Highly scalable; relies on supplier efficiency |

| Control | More control over product quality and packaging | Less control; depends on supplier fulfillment accuracy |

Understanding Inventory Management in Dropshipping

Inventory management in dropshipping involves tracking stock levels, product availability, and supplier lead times to ensure timely order fulfillment without holding physical stock. Effective inventory management minimizes the risk of overselling and stockouts by synchronizing data from multiple suppliers and sales channels. Understanding these processes enables dropshippers to maintain customer satisfaction while optimizing operational efficiency.

What is Just-In-Time Fulfillment?

Just-In-Time fulfillment is a dropshipping inventory strategy where products are sourced and shipped directly from suppliers only after a customer places an order, minimizing the need to hold stock. This approach reduces storage costs, lowers the risk of overstocking, and improves cash flow by aligning inventory levels closely with demand. Effective implementation relies on strong supplier relationships and real-time order processing to ensure prompt delivery and customer satisfaction.

Key Differences Between Inventory Management and JIT

Inventory management involves maintaining a stock of products to meet customer demand, ensuring availability and reducing lead times, while Just-In-Time (JIT) fulfillment minimizes inventory by receiving goods only as needed, reducing holding costs and waste. Inventory management requires forecasting and storage capacity, whereas JIT depends heavily on reliable supplier relationships and precise demand prediction. The key difference lies in inventory control: inventory management emphasizes stock accumulation, whereas JIT focuses on lean operations with minimal stored inventory.

Pros and Cons of Traditional Inventory Management

Traditional inventory management in dropshipping offers the advantage of immediate product availability, enabling faster order fulfillment and potentially higher customer satisfaction. However, it involves higher upfront costs, increased risk of overstocking or obsolescence, and greater demand for warehouse space and storage management. Businesses must balance these factors against the flexibility and lower storage risk provided by just-in-time fulfillment models.

Advantages of Just-In-Time Fulfillment for Dropshippers

Just-In-Time Fulfillment minimizes inventory holding costs and reduces the risk of overstocking by syncing product orders directly with customer demand. Dropshippers benefit from lower capital investment and increased cash flow, as products are shipped only when purchased. This streamlined approach enhances operational efficiency and enables rapid adaptation to market trends without inventory constraints.

Impact on Cash Flow: Inventory vs JIT

Maintaining inventory in dropshipping ties up capital in stock, potentially reducing cash flow flexibility and increasing storage costs. Just-In-Time (JIT) fulfillment minimizes upfront investment by ordering products only after customer purchase, improving cash flow efficiency and reducing the risk of unsold inventory. However, JIT may expose businesses to supplier delays, impacting order fulfillment speed and customer satisfaction.

Risk Management: Stockouts and Overstocking

Effective inventory management minimizes risks of stockouts by maintaining safety stock levels, ensuring product availability during demand fluctuations in dropshipping. Just-In-time fulfillment reduces overstocking risks by aligning inventory arrival with customer orders, cutting storage costs and minimizing obsolete inventory. Balancing these strategies optimizes cash flow, enhances customer satisfaction, and mitigates financial losses from excess or insufficient stock.

Scalability: Which Model Supports Growth?

Inventory management systems provide scalability by allowing businesses to stock products in advance, ensuring faster order fulfillment and improved customer satisfaction during periods of high demand. Just-in-time fulfillment minimizes holding costs and reduces risk by sourcing products only when orders are placed, supporting flexible growth without heavy investment in storage. Choosing the right model depends on balancing capital availability and the ability to scale quickly while maintaining supply chain efficiency in dropshipping operations.

Technology Solutions for Effective Fulfillment

Dropshipping leverages technology solutions like inventory management systems and Just-In-Time (JIT) fulfillment software to optimize order processing and reduce holding costs. Advanced platforms integrate real-time inventory tracking, automated supplier coordination, and predictive analytics to prevent stockouts and overstock situations. Utilizing cloud-based tools and AI-driven demand forecasting enhances accuracy and speeds up fulfillment cycles, driving efficient and scalable dropshipping operations.

Choosing the Best Model for Your Dropshipping Business

Inventory management in dropshipping involves maintaining stock levels to ensure product availability, enhancing customer satisfaction through faster shipping times. Just-In-Time fulfillment minimizes holding costs by synchronizing orders directly with suppliers, reducing inventory risks but potentially extending delivery times. Selecting the optimal model depends on factors like product demand predictability, supplier reliability, and cash flow constraints to balance efficiency and customer experience.

Inventory Management vs Just-In-Time Fulfillment Infographic

bizdif.com

bizdif.com