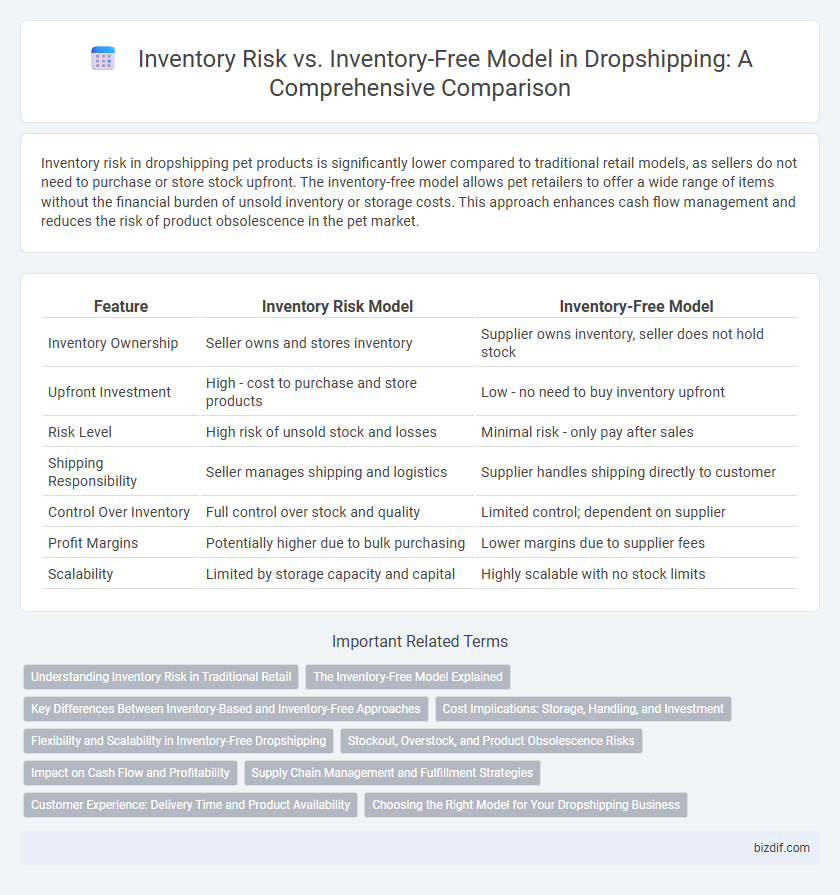

Inventory risk in dropshipping pet products is significantly lower compared to traditional retail models, as sellers do not need to purchase or store stock upfront. The inventory-free model allows pet retailers to offer a wide range of items without the financial burden of unsold inventory or storage costs. This approach enhances cash flow management and reduces the risk of product obsolescence in the pet market.

Table of Comparison

| Feature | Inventory Risk Model | Inventory-Free Model |

|---|---|---|

| Inventory Ownership | Seller owns and stores inventory | Supplier owns inventory, seller does not hold stock |

| Upfront Investment | High - cost to purchase and store products | Low - no need to buy inventory upfront |

| Risk Level | High risk of unsold stock and losses | Minimal risk - only pay after sales |

| Shipping Responsibility | Seller manages shipping and logistics | Supplier handles shipping directly to customer |

| Control Over Inventory | Full control over stock and quality | Limited control; dependent on supplier |

| Profit Margins | Potentially higher due to bulk purchasing | Lower margins due to supplier fees |

| Scalability | Limited by storage capacity and capital | Highly scalable with no stock limits |

Understanding Inventory Risk in Traditional Retail

Inventory risk in traditional retail involves significant financial exposure due to unsold stock, leading to potential losses from markdowns, spoilage, or obsolescence. Retailers must invest capital upfront to purchase and store inventory, creating cash flow challenges and limiting flexibility in responding to market demand fluctuations. This contrasts with the inventory-free model in dropshipping, where stock is held by suppliers, minimizing risk and operational costs for the retailer.

The Inventory-Free Model Explained

The inventory-free model in dropshipping eliminates the need for sellers to stock products, significantly reducing inventory risk and upfront costs. Sellers act as intermediaries, listing products from suppliers who handle storage, packaging, and shipping directly to customers. This streamlined approach allows businesses to scale quickly without the burden of managing physical inventory or facing losses from unsold stock.

Key Differences Between Inventory-Based and Inventory-Free Approaches

Inventory-based dropshipping requires upfront stock investment, leading to higher inventory risk and potential holding costs, while inventory-free models eliminate stock ownership, minimizing financial risk and storage expenses. Inventory-based approaches offer faster shipping and better control over product quality, whereas inventory-free methods rely on suppliers for fulfillment, often resulting in variable delivery times and quality consistency. Key differences lie in capital requirements, risk exposure, and operational control, making inventory-based suitable for businesses prioritizing control, and inventory-free ideal for low-risk, scalable ventures.

Cost Implications: Storage, Handling, and Investment

Inventory risk involves significant cost implications including storage fees, handling expenses, and upfront capital investment for stock procurement. The inventory-free model eliminates the need for warehousing and reduces handling costs since products are shipped directly from suppliers, minimizing financial risk. By avoiding inventory holding, dropshippers can allocate resources more efficiently, lowering operational costs and improving cash flow management.

Flexibility and Scalability in Inventory-Free Dropshipping

Inventory-free dropshipping offers exceptional flexibility by eliminating the need for upfront investment in stock, allowing businesses to quickly adapt to market trends and customer demands without the burden of excess inventory. Scalability is significantly enhanced as sellers can expand product offerings or enter new markets without logistical constraints or increased storage costs. This model reduces financial risk and supports rapid growth, making it ideal for entrepreneurs seeking low-risk, highly adaptable e-commerce solutions.

Stockout, Overstock, and Product Obsolescence Risks

Dropshipping significantly reduces inventory risk by eliminating the need to hold stock, thus minimizing stockout, overstock, and product obsolescence risks. Traditional inventory models face frequent stockouts due to demand forecasting errors and overstock challenges that tie up capital and increase holding costs. Product obsolescence risk is heightened in conventional inventory systems as unsold items lose market relevance, whereas dropshipping leverages real-time supplier fulfillment to avoid these pitfalls.

Impact on Cash Flow and Profitability

Inventory risk in dropshipping ties up capital in unsold stock, negatively impacting cash flow and reducing profitability due to storage costs and potential obsolescence. The inventory-free model minimizes upfront investment, enhancing cash flow by only purchasing products after a customer order, which leads to higher profitability through reduced overhead. However, relying on suppliers' stock levels can introduce fulfillment delays, affecting customer satisfaction and repeat sales.

Supply Chain Management and Fulfillment Strategies

Inventory risk in dropshipping is minimized by adopting an inventory-free model, allowing businesses to avoid holding stock and reduce capital investment. Effective supply chain management relies on real-time supplier coordination and streamlined order fulfillment strategies to ensure prompt delivery and customer satisfaction. Leveraging automated inventory tracking and demand forecasting tools enhances accuracy in managing supplier availability and prevents fulfillment delays.

Customer Experience: Delivery Time and Product Availability

Inventory risk models often lead to faster delivery times and higher product availability, enhancing customer satisfaction by reducing wait times and backorders. Inventory-free dropshipping models can struggle with longer delivery times and inconsistent stock levels due to reliance on third-party suppliers. Optimizing supply chain coordination is essential to balancing delivery speed and product availability in both models, ultimately impacting customer experience.

Choosing the Right Model for Your Dropshipping Business

Choosing the right inventory model for your dropshipping business hinges on balancing inventory risk and operational flexibility. An inventory-free model minimizes upfront investment and eliminates stockholding costs, enabling entrepreneurs to test products with low financial risk. Conversely, managing inventory offers greater control over product quality and shipping times but requires capital investment and exposes the business to potential overstock or stockout issues.

Inventory risk vs inventory-free model Infographic

bizdif.com

bizdif.com