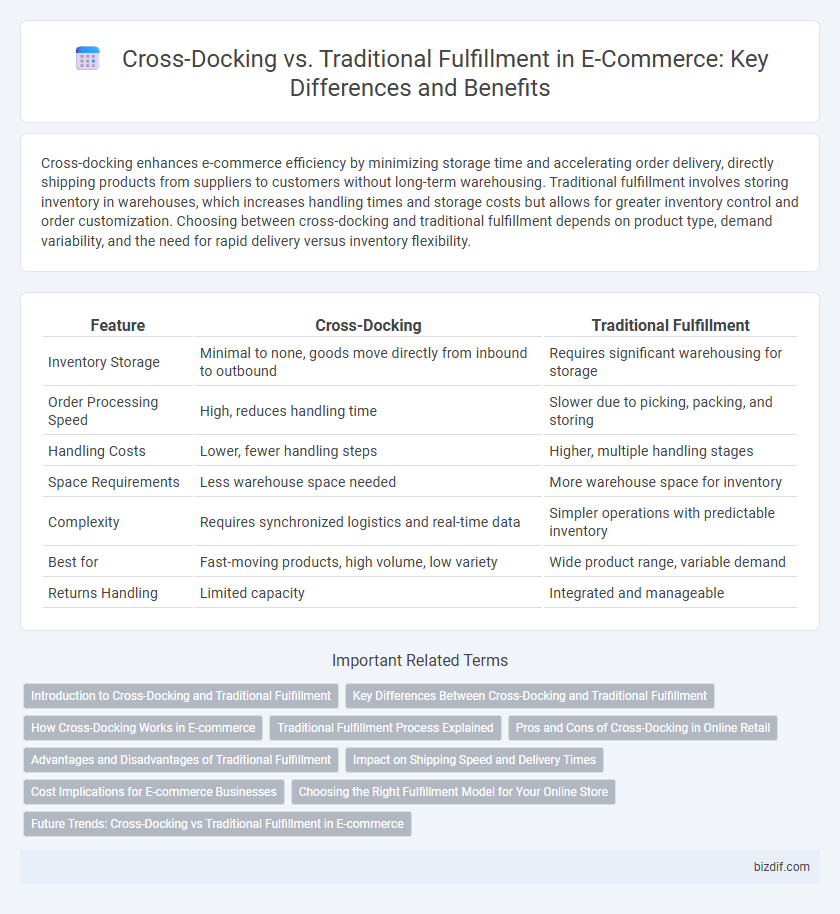

Cross-docking enhances e-commerce efficiency by minimizing storage time and accelerating order delivery, directly shipping products from suppliers to customers without long-term warehousing. Traditional fulfillment involves storing inventory in warehouses, which increases handling times and storage costs but allows for greater inventory control and order customization. Choosing between cross-docking and traditional fulfillment depends on product type, demand variability, and the need for rapid delivery versus inventory flexibility.

Table of Comparison

| Feature | Cross-Docking | Traditional Fulfillment |

|---|---|---|

| Inventory Storage | Minimal to none, goods move directly from inbound to outbound | Requires significant warehousing for storage |

| Order Processing Speed | High, reduces handling time | Slower due to picking, packing, and storing |

| Handling Costs | Lower, fewer handling steps | Higher, multiple handling stages |

| Space Requirements | Less warehouse space needed | More warehouse space for inventory |

| Complexity | Requires synchronized logistics and real-time data | Simpler operations with predictable inventory |

| Best for | Fast-moving products, high volume, low variety | Wide product range, variable demand |

| Returns Handling | Limited capacity | Integrated and manageable |

Introduction to Cross-Docking and Traditional Fulfillment

Cross-docking is a logistics strategy where products are directly transferred from inbound to outbound transportation with minimal storage time, enhancing speed and reducing warehouse costs. Traditional fulfillment involves storing inventory in warehouses until orders are received, requiring more storage space and longer processing times. E-commerce businesses leverage cross-docking to optimize supply chain efficiency while traditional fulfillment supports bulk inventory management and order accuracy.

Key Differences Between Cross-Docking and Traditional Fulfillment

Cross-docking minimizes inventory holding by directly transferring products from inbound to outbound transportation, reducing storage costs and speeding up order fulfillment. Traditional fulfillment relies on warehousing goods until orders are received, allowing for more inventory control but increasing storage expenses and processing times. Cross-docking enhances supply chain efficiency through faster turnaround, while traditional fulfillment supports diverse product assortments and customization options.

How Cross-Docking Works in E-commerce

Cross-docking in e-commerce streamlines the supply chain by directly transferring products from inbound to outbound shipments, minimizing storage time and reducing warehousing costs. This process relies heavily on synchronized logistics, real-time inventory tracking, and advanced warehouse management systems to ensure immediate sorting and dispatching of goods. By accelerating order fulfillment and improving inventory turnover, cross-docking enhances customer satisfaction and operational efficiency compared to traditional fulfillment.

Traditional Fulfillment Process Explained

Traditional fulfillment involves storing inventory in warehouses until customer orders are received, followed by picking, packing, and shipping products directly from these storage facilities. This process requires significant warehousing space and labor, often leading to longer delivery times compared to cross-docking. Inventory management accuracy and efficient order processing are critical to minimizing delays and reducing operational costs in traditional fulfillment systems.

Pros and Cons of Cross-Docking in Online Retail

Cross-docking in online retail minimizes storage costs by transferring products directly from inbound to outbound shipments, enhancing delivery speed and reducing inventory holding risks. However, it requires precise coordination and real-time data integration to prevent bottlenecks and ensure accurate order fulfillment. Limited flexibility in handling product customization and dependency on supplier reliability can pose challenges compared to traditional fulfillment models.

Advantages and Disadvantages of Traditional Fulfillment

Traditional fulfillment offers comprehensive order accuracy and extensive inventory control by storing products before shipment, enhancing quality checks and reducing stockouts. However, it involves higher warehousing costs, longer delivery times due to storage and picking processes, and increased risk of excess inventory. This method suits businesses prioritizing order customization and reliability over rapid delivery speed.

Impact on Shipping Speed and Delivery Times

Cross-docking significantly accelerates shipping speed by minimizing storage time as products move directly from inbound to outbound shipping docks, reducing delivery times compared to traditional fulfillment, which involves longer handling and storage processes. Traditional fulfillment relies on warehousing inventory before order processing, resulting in extended lead times and slower delivery. E-commerce businesses adopting cross-docking benefit from faster order turnaround and enhanced customer satisfaction through quicker delivery windows.

Cost Implications for E-commerce Businesses

Cross-docking minimizes inventory holding costs by enabling direct transfer of goods from inbound to outbound shipments, reducing storage fees and handling expenses common in traditional fulfillment. Traditional fulfillment involves higher warehousing costs due to prolonged storage and increased labor for order picking, packing, and inventory management. E-commerce businesses adopting cross-docking benefit from faster turnover and lower capital tied up in inventory, resulting in significant cost savings and improved cash flow management.

Choosing the Right Fulfillment Model for Your Online Store

Cross-docking minimizes inventory holding costs by transferring products directly from inbound to outbound shipping, ideal for perishable goods or high-demand items in e-commerce. Traditional fulfillment involves storing inventory in a warehouse before order processing, offering greater control over stock accuracy and customization options. Selecting the right fulfillment model depends on product type, order volume, and delivery speed requirements to optimize operational efficiency and customer satisfaction.

Future Trends: Cross-Docking vs Traditional Fulfillment in E-commerce

Future trends in e-commerce highlight the growing adoption of cross-docking due to its efficiency in reducing delivery times and inventory holding costs. Traditional fulfillment still dominates for complex order customization but faces pressure from demands for faster shipping and real-time inventory management. Integration of AI and IoT technologies is expected to further optimize cross-docking processes, enhancing supply chain visibility and responsiveness.

Cross-docking vs Traditional Fulfillment Infographic

bizdif.com

bizdif.com