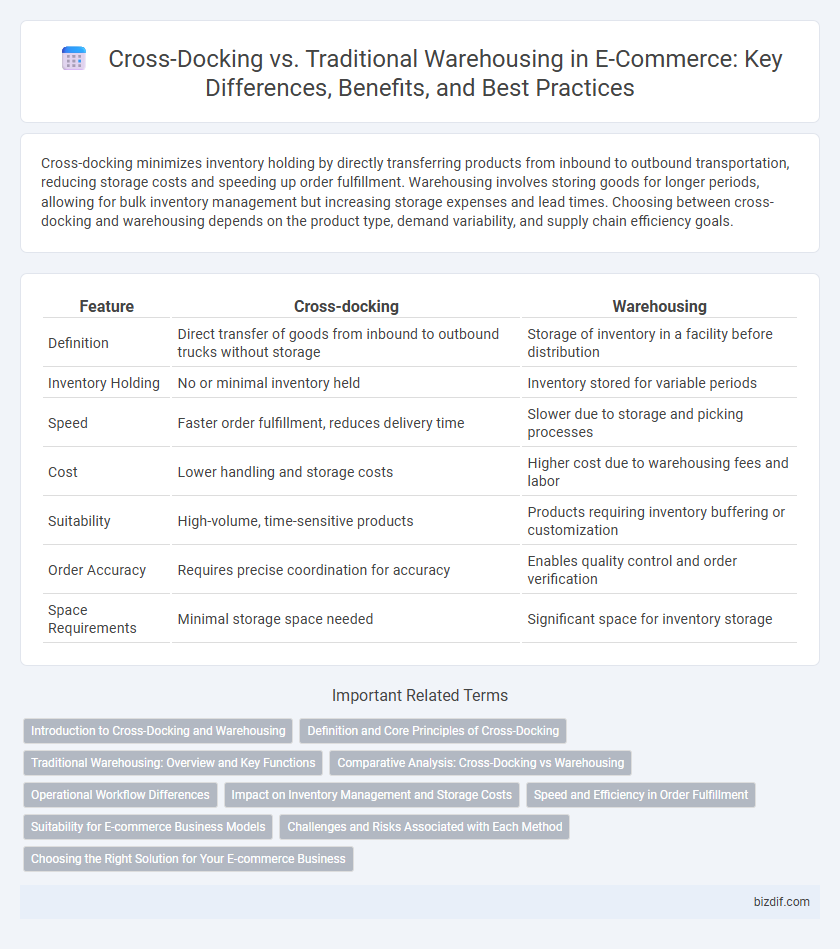

Cross-docking minimizes inventory holding by directly transferring products from inbound to outbound transportation, reducing storage costs and speeding up order fulfillment. Warehousing involves storing goods for longer periods, allowing for bulk inventory management but increasing storage expenses and lead times. Choosing between cross-docking and warehousing depends on the product type, demand variability, and supply chain efficiency goals.

Table of Comparison

| Feature | Cross-docking | Warehousing |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound trucks without storage | Storage of inventory in a facility before distribution |

| Inventory Holding | No or minimal inventory held | Inventory stored for variable periods |

| Speed | Faster order fulfillment, reduces delivery time | Slower due to storage and picking processes |

| Cost | Lower handling and storage costs | Higher cost due to warehousing fees and labor |

| Suitability | High-volume, time-sensitive products | Products requiring inventory buffering or customization |

| Order Accuracy | Requires precise coordination for accuracy | Enables quality control and order verification |

| Space Requirements | Minimal storage space needed | Significant space for inventory storage |

Introduction to Cross-Docking and Warehousing

Cross-docking streamlines e-commerce supply chains by transferring products directly from inbound to outbound transportation, reducing storage time and lowering inventory costs. Warehousing involves storing goods for extended periods, enabling better inventory management but increasing handling and storage expenses. Efficient e-commerce operations often balance cross-docking's speed with warehousing's inventory control to optimize order fulfillment.

Definition and Core Principles of Cross-Docking

Cross-docking is a logistics strategy where incoming shipments are directly transferred from inbound to outbound transportation with minimal or no storage time, enhancing inventory turnover and reducing handling costs. Unlike traditional warehousing, which involves storing goods for extended periods before distribution, cross-docking emphasizes rapid sorting, consolidation, and immediate shipment to end customers or retail locations. Key principles include synchronized inbound and outbound schedules, streamlined material handling processes, and real-time information systems to optimize flow and reduce lead times in the supply chain.

Traditional Warehousing: Overview and Key Functions

Traditional warehousing serves as a centralized storage facility where goods are received, stored, and managed until they are distributed to retailers or customers. Key functions include inventory management, order fulfillment, and ensuring product safety through controlled environments and security measures. Efficient warehousing optimizes supply chain operations by reducing lead times and managing stock levels to meet customer demand.

Comparative Analysis: Cross-Docking vs Warehousing

Cross-docking minimizes inventory holding by transferring products directly from inbound to outbound transportation, reducing storage costs and improving delivery speed. Warehousing involves storing goods for longer periods, offering inventory flexibility and consolidation but increasing storage expenses and lead times. E-commerce businesses benefit from cross-docking for fast-moving goods requiring rapid turnover, while warehousing suits bulky or slow-moving inventory needing secure, long-term storage.

Operational Workflow Differences

Cross-docking streamlines the operational workflow by directly transferring incoming goods from inbound to outbound transportation, minimizing storage time and reducing handling costs. Warehousing involves receiving, storing, and inventory management, requiring a more complex workflow with picking, packing, and order fulfillment tasks. E-commerce businesses relying on cross-docking benefit from faster delivery cycles, while traditional warehousing supports extensive inventory control and bulk storage.

Impact on Inventory Management and Storage Costs

Cross-docking significantly reduces inventory holding costs by minimizing storage time, as products move directly from inbound to outbound shipments without long-term warehousing. Warehousing involves stocking goods for extended periods, increasing inventory carrying costs and requiring more extensive space management. Efficient cross-docking optimizes inventory turnover rates, cutting storage expenses and improving supply chain responsiveness compared to traditional warehousing.

Speed and Efficiency in Order Fulfillment

Cross-docking significantly enhances speed in order fulfillment by directly transferring products from inbound to outbound transportation, bypassing storage and reducing handling time. Warehousing, while essential for inventory management, introduces longer lead times due to storage and picking processes, impacting overall efficiency. Leveraging cross-docking can optimize supply chain operations by minimizing delays and streamlining inventory flow, crucial for meeting rapid e-commerce demand.

Suitability for E-commerce Business Models

Cross-docking optimizes fast-moving e-commerce models by minimizing storage time and reducing inventory costs, making it ideal for businesses with high turnover and just-in-time delivery requirements. Warehousing suits e-commerce businesses with diverse product catalogs and variable order volumes, providing storage flexibility and allowing for bulk inventory management. Selecting the right logistics strategy depends on factors like order frequency, product variety, and delivery speed expectations within the e-commerce framework.

Challenges and Risks Associated with Each Method

Cross-docking faces challenges such as tight scheduling requirements, risk of inventory shortages, and dependency on real-time data accuracy, which can lead to operational disruptions and increased transportation costs. Warehousing involves risks related to higher inventory holding costs, potential for product obsolescence, and the need for expansive storage space that can impact cash flow and inventory turnover rates. Both methods require robust supply chain management systems to mitigate risks and optimize efficiency, balancing speed with inventory control.

Choosing the Right Solution for Your E-commerce Business

Cross-docking streamlines order fulfillment by reducing storage time and accelerating delivery, ideal for e-commerce businesses with high-volume, fast-moving products. Warehousing offers secure inventory storage and better stock management, suitable for businesses with diverse product ranges and variable demand. Assessing factors like order frequency, inventory turnover, and customer expectations ensures the optimal logistics solution for your e-commerce operation.

Cross-docking vs Warehousing Infographic

bizdif.com

bizdif.com