Artisanal pottery showcases unique craftsmanship and cultural heritage through hand-shaped and hand-painted designs that highlight individual artistry. Mass-produced ceramics prioritize uniformity and cost-efficiency, often lacking the distinctive character found in handcrafted pieces. Choosing artisanal pottery supports traditional techniques and ensures each item possesses a one-of-a-kind aesthetic appeal.

Table of Comparison

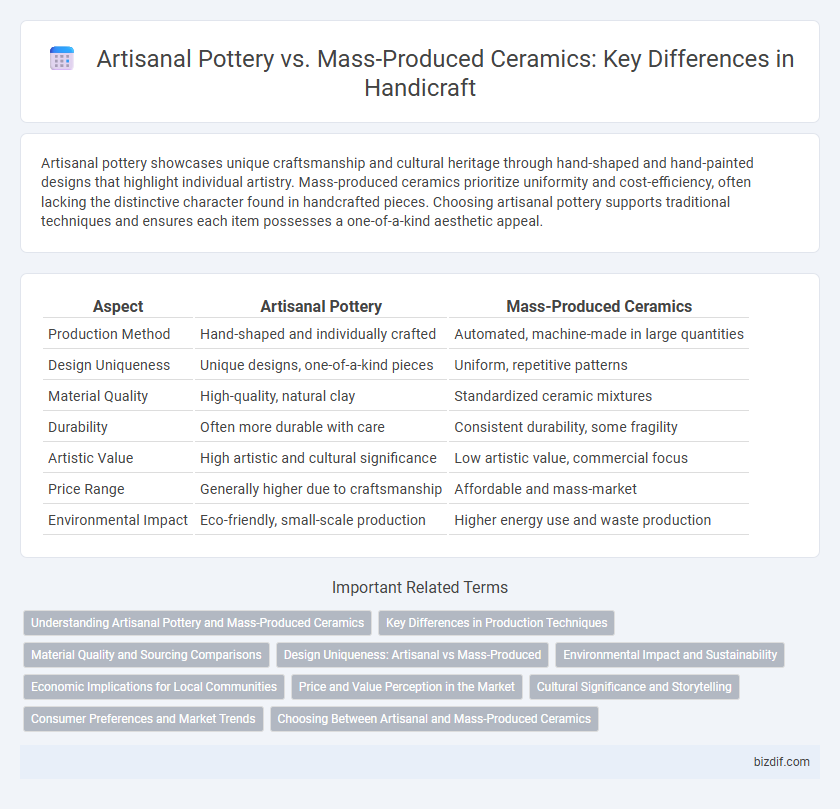

| Aspect | Artisanal Pottery | Mass-Produced Ceramics |

|---|---|---|

| Production Method | Hand-shaped and individually crafted | Automated, machine-made in large quantities |

| Design Uniqueness | Unique designs, one-of-a-kind pieces | Uniform, repetitive patterns |

| Material Quality | High-quality, natural clay | Standardized ceramic mixtures |

| Durability | Often more durable with care | Consistent durability, some fragility |

| Artistic Value | High artistic and cultural significance | Low artistic value, commercial focus |

| Price Range | Generally higher due to craftsmanship | Affordable and mass-market |

| Environmental Impact | Eco-friendly, small-scale production | Higher energy use and waste production |

Understanding Artisanal Pottery and Mass-Produced Ceramics

Artisanal pottery is crafted by skilled artisans using traditional techniques that emphasize uniqueness, texture, and cultural heritage, resulting in pieces with distinct character and varying imperfections. Mass-produced ceramics are manufactured in large quantities using automated processes, ensuring uniformity, affordability, and consistency in design and durability. Understanding these differences highlights the value of handmade artistry versus the efficiency and scalability of industrial production methods.

Key Differences in Production Techniques

Artisanal pottery employs traditional hand-building and wheel-throwing methods, allowing for unique, handcrafted designs and individual craftsmanship in every piece. In contrast, mass-produced ceramics rely on automated processes like slip casting and mold pressing, resulting in uniformity and high-volume output. The artisanal approach emphasizes manual skill and natural clay variations, while mass production prioritizes consistency and efficiency through mechanization.

Material Quality and Sourcing Comparisons

Artisanal pottery typically employs high-quality, locally sourced natural clays and traditional glazing techniques, resulting in durable and unique pieces with rich textures. Mass-produced ceramics often use standardized, clay blends and synthetic materials to maximize cost-efficiency, leading to uniform shapes but less material integrity. The sustainability and authenticity of artisanal materials contrast sharply with the industrial sourcing and chemical additives common in mass production.

Design Uniqueness: Artisanal vs Mass-Produced

Artisanal pottery showcases unique design elements crafted by skilled artisans, resulting in one-of-a-kind pieces with intricate details and natural variations. Mass-produced ceramics rely on uniform molds and automated processes, yielding consistent but repetitive patterns and shapes lacking individual character. The design uniqueness of artisanal pottery adds cultural value and aesthetic appeal that mass-produced ceramics often cannot replicate.

Environmental Impact and Sustainability

Artisanal pottery typically has a lower environmental impact due to its reliance on local materials, traditional techniques, and minimal energy consumption compared to mass-produced ceramics that often involve high-energy industrial processes and synthetic materials. The sustainability of handcrafted ceramics is enhanced by their durability, repairability, and reduced carbon footprint during production. In contrast, mass-produced ceramics generate significant waste and pollution, contributing to environmental degradation over time.

Economic Implications for Local Communities

Artisanal pottery contributes significantly to local economies by creating jobs and preserving traditional skills, fostering sustainable income for communities. In contrast, mass-produced ceramics often lead to economic leakage as profits flow to large corporations, diminishing local financial benefits. Supporting artisanal pottery enhances cultural heritage and strengthens economic resilience in local markets.

Price and Value Perception in the Market

Artisanal pottery commands higher prices due to its unique craftsmanship, limited editions, and cultural authenticity, leading to a stronger perceived value in niche markets. Mass-produced ceramics are priced lower because of economies of scale and standardized production, appealing to budget-conscious consumers seeking functionality over exclusivity. The value perception in the market favors artisanal pottery for collectors and connoisseurs, while mass-produced ceramics dominate the volume-driven retail segment.

Cultural Significance and Storytelling

Artisanal pottery uniquely preserves cultural heritage by incorporating traditional techniques and symbolic designs passed down through generations, often reflecting the artisan's personal narrative and regional identity. Mass-produced ceramics lack this cultural depth, prioritizing uniformity and functionality over storytelling, resulting in objects that are disconnected from specific cultural contexts. The cultural significance embedded in artisanal pottery fosters a deeper emotional connection and appreciation, highlighting the importance of individual craftsmanship in maintaining cultural traditions.

Consumer Preferences and Market Trends

Artisanal pottery appeals to consumers who prioritize unique craftsmanship, cultural authenticity, and sustainability, driving demand in niche markets focused on handmade goods. Mass-produced ceramics dominate mainstream retail due to affordability, uniformity, and widespread availability, catering to cost-conscious buyers seeking functional everyday items. Current market trends reveal a growing shift toward artisanal pottery as consumers increasingly value eco-friendly materials and personalized designs over mass-produced alternatives.

Choosing Between Artisanal and Mass-Produced Ceramics

Artisanal pottery offers unique designs and superior craftsmanship due to the meticulous hand-shaping and glazing techniques used by skilled artisans. Mass-produced ceramics provide consistency, affordability, and wide availability, benefiting from automated manufacturing processes. Choosing between the two depends on valuing individuality and artistic expression versus practicality and cost-efficiency in ceramic products.

Artisanal pottery vs Mass-produced ceramics Infographic

bizdif.com

bizdif.com