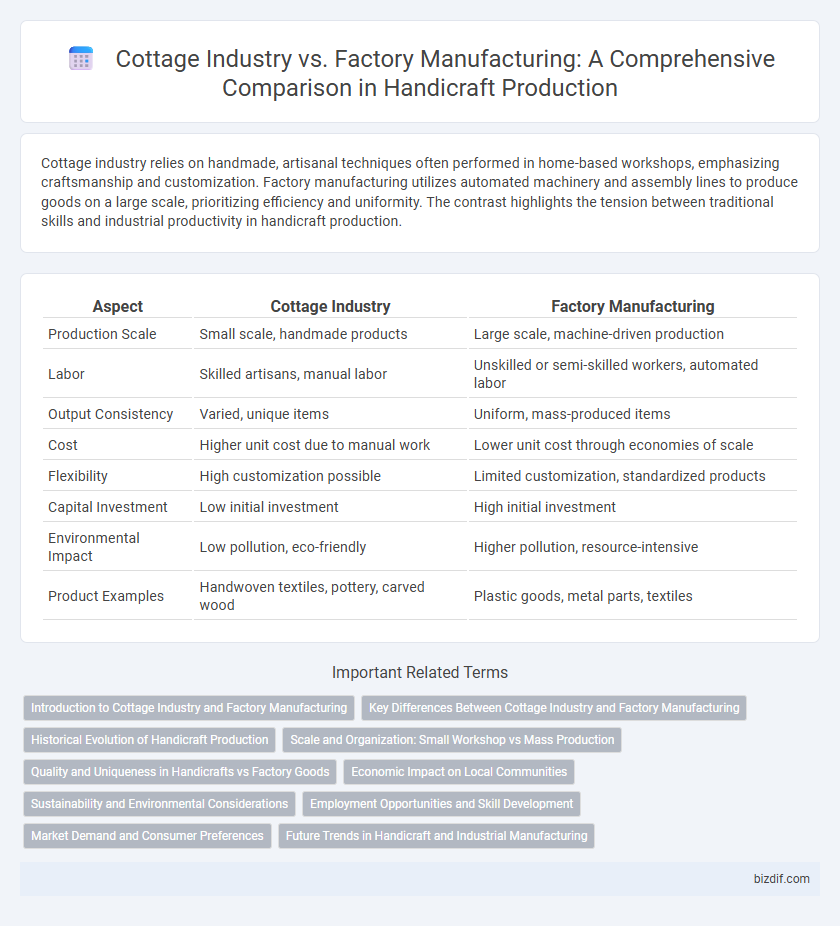

Cottage industry relies on handmade, artisanal techniques often performed in home-based workshops, emphasizing craftsmanship and customization. Factory manufacturing utilizes automated machinery and assembly lines to produce goods on a large scale, prioritizing efficiency and uniformity. The contrast highlights the tension between traditional skills and industrial productivity in handicraft production.

Table of Comparison

| Aspect | Cottage Industry | Factory Manufacturing |

|---|---|---|

| Production Scale | Small scale, handmade products | Large scale, machine-driven production |

| Labor | Skilled artisans, manual labor | Unskilled or semi-skilled workers, automated labor |

| Output Consistency | Varied, unique items | Uniform, mass-produced items |

| Cost | Higher unit cost due to manual work | Lower unit cost through economies of scale |

| Flexibility | High customization possible | Limited customization, standardized products |

| Capital Investment | Low initial investment | High initial investment |

| Environmental Impact | Low pollution, eco-friendly | Higher pollution, resource-intensive |

| Product Examples | Handwoven textiles, pottery, carved wood | Plastic goods, metal parts, textiles |

Introduction to Cottage Industry and Factory Manufacturing

Cottage industry involves small-scale, home-based production where artisans use traditional methods and manual tools to create handcrafted goods, emphasizing quality and cultural heritage. Factory manufacturing operates on an industrial scale with mechanized processes, assembly lines, and advanced technology to produce large quantities of standardized products efficiently. The contrast between cottage industry's personalized craftsmanship and factory manufacturing's mass production highlights different economic, social, and environmental impacts within the handicraft sector.

Key Differences Between Cottage Industry and Factory Manufacturing

Cottage industry primarily involves small-scale, manual production often conducted at home using traditional methods, whereas factory manufacturing relies on large-scale, mechanized processes within centralized facilities. Cottage industries emphasize handmade, unique, and customizable products, while factory manufacturing prioritizes mass production, uniformity, and efficiency. Labor intensity and skill level differ significantly, with cottage industries depending on skilled artisans and factory setups leveraging automated machinery and division of labor.

Historical Evolution of Handicraft Production

Handicraft production historically began as a cottage industry where artisans created goods by hand in small workshops or homes, emphasizing skill and individuality. The Industrial Revolution introduced factory manufacturing, centralizing production with mechanized processes to increase scale and uniformity. This shift transformed handicraft from localized, labor-intensive practices into mass production, significantly impacting economic and social structures.

Scale and Organization: Small Workshop vs Mass Production

Cottage industry operates on a small scale with handcrafted products made in home-based or small workshop settings, emphasizing artisanal skills and limited output. Factory manufacturing involves mass production in large-scale facilities using automated machines and assembly lines, allowing for high volume and uniform quality. The organization in cottage industries is often informal and flexible, whereas factories maintain structured hierarchies and standardized processes to optimize efficiency.

Quality and Uniqueness in Handicrafts vs Factory Goods

Handicrafts from cottage industries exhibit superior quality and uniqueness due to meticulous attention to detail and traditional craftsmanship techniques passed down through generations. Factory manufacturing prioritizes mass production efficiency, often resulting in uniform products with less individuality and artisanal value. The inherent variability and personalized touch in handmade items significantly enhance their cultural and aesthetic appeal compared to standardized factory goods.

Economic Impact on Local Communities

Cottage industries generate significant economic benefits for local communities by promoting employment and preserving traditional skills, often requiring minimal capital investment and supporting sustainable livelihoods. Factory manufacturing boosts economic scale through mass production, leading to increased output and potential for export, but may concentrate wealth and reduce local job diversity. Balancing these sectors can enhance economic resilience, ensuring both community empowerment and industrial growth.

Sustainability and Environmental Considerations

Cottage industry in handicrafts often prioritizes sustainability by using locally sourced, natural materials with minimal environmental impact, reducing carbon footprints through small-scale production. Factory manufacturing typically involves large-scale operations that may lead to higher energy consumption, waste generation, and pollution despite potential efficiencies in material usage. Emphasizing eco-friendly practices and waste reduction is crucial for both sectors to minimize their environmental footprint and promote sustainable handicraft production.

Employment Opportunities and Skill Development

Cottage industry fosters employment by enabling artisans to work from home, preserving traditional skills and promoting craftsmanship in local communities. Factory manufacturing provides large-scale job opportunities, emphasizing specialized skills through structured training programs and enhancing workforce efficiency. The balance between cottage industry and factory manufacturing shapes economic growth by diversifying employment prospects and advancing skill development across sectors.

Market Demand and Consumer Preferences

Cottage industry products often cater to niche markets with consumer preferences for unique, handcrafted items that emphasize cultural heritage and artisanal quality. Factory manufacturing meets high market demand by producing large volumes of uniform goods, appealing to consumers seeking affordability and consistency. Rising consumer interest in sustainable and ethically made products increasingly favors cottage industries, impacting market dynamics and supply chain strategies.

Future Trends in Handicraft and Industrial Manufacturing

Future trends in handicraft emphasize sustainable materials, personalized products, and the integration of digital tools like 3D printing to enhance craftsmanship. Industrial manufacturing is increasingly adopting automation, AI-driven quality control, and smart supply chain management to boost efficiency and reduce waste. Emerging hybrid models blend cottage industry creativity with factory-scale production, fostering innovation and market adaptability.

Cottage Industry vs Factory Manufacturing Infographic

bizdif.com

bizdif.com