Traditional craftsmanship emphasizes the artistry and cultural heritage embedded in handcrafted items, offering unique designs and superior quality through skills passed down generations. Modern manufacturing prioritizes efficiency, scalability, and uniformity, enabling mass production with reduced costs and faster turnaround times. Balancing these approaches can preserve artisanal value while meeting contemporary market demands.

Table of Comparison

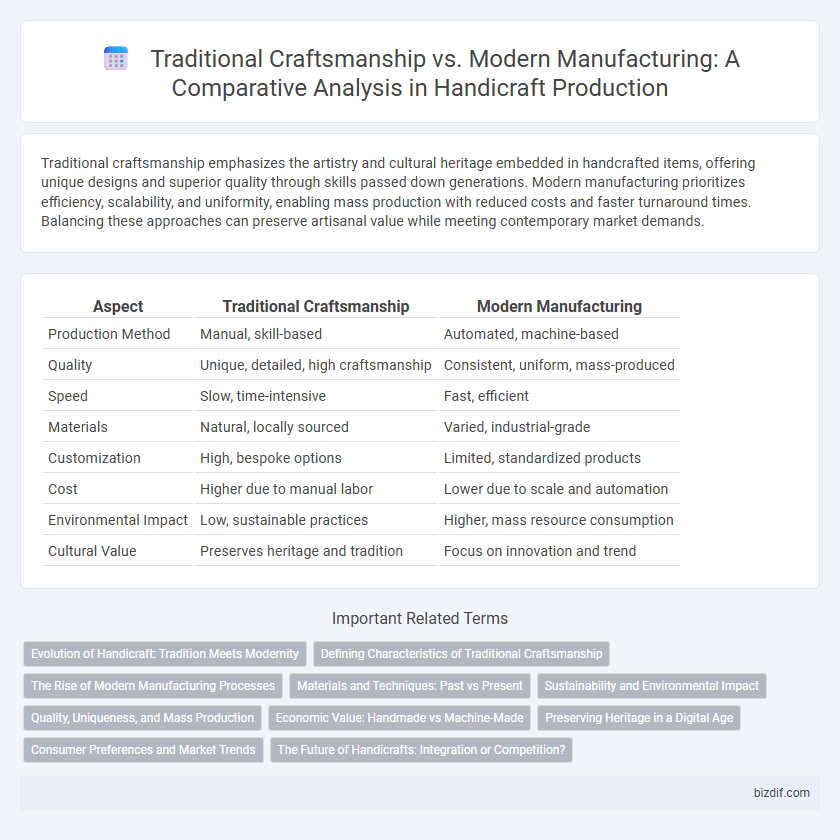

| Aspect | Traditional Craftsmanship | Modern Manufacturing |

|---|---|---|

| Production Method | Manual, skill-based | Automated, machine-based |

| Quality | Unique, detailed, high craftsmanship | Consistent, uniform, mass-produced |

| Speed | Slow, time-intensive | Fast, efficient |

| Materials | Natural, locally sourced | Varied, industrial-grade |

| Customization | High, bespoke options | Limited, standardized products |

| Cost | Higher due to manual labor | Lower due to scale and automation |

| Environmental Impact | Low, sustainable practices | Higher, mass resource consumption |

| Cultural Value | Preserves heritage and tradition | Focus on innovation and trend |

Evolution of Handicraft: Tradition Meets Modernity

Traditional craftsmanship preserves intricate techniques and cultural heritage through hands-on skills passed down generations, emphasizing uniqueness and authenticity in each piece. Modern manufacturing incorporates advanced technology and automation, enabling mass production with consistent quality but often sacrificing individuality and artisan touch. The evolution of handicraft merges these approaches, blending traditional artistry with innovative tools to create products that honor heritage while meeting contemporary market demands.

Defining Characteristics of Traditional Craftsmanship

Traditional craftsmanship is defined by its emphasis on manual skills, attention to detail, and use of natural materials, creating unique and high-quality handmade products. Each piece reflects cultural heritage and artisan expertise, often produced in limited quantities with time-honored techniques passed down through generations. This approach prioritizes durability, authenticity, and intricate artistry over mass production and uniformity found in modern manufacturing.

The Rise of Modern Manufacturing Processes

Modern manufacturing processes have revolutionized production by integrating automation, advanced machinery, and precision technologies, enabling mass production with consistent quality and efficiency. This shift has significantly reduced costs and production time compared to traditional craftsmanship, which relies heavily on manual skill and time-intensive methods. Despite this, the tactile uniqueness and cultural value of handcrafted goods continue to appeal to niche markets seeking authenticity and artisanal quality.

Materials and Techniques: Past vs Present

Traditional craftsmanship relies on natural materials such as wood, clay, and fibers, employing time-honored techniques like hand carving, weaving, and pottery that emphasize skill and individuality. Modern manufacturing utilizes synthetic materials, metals, and plastics combined with automated processes like 3D printing, CNC machining, and mass production to achieve precision and scalability. The contrast between these approaches highlights a shift from artisanal, labor-intensive methods toward efficient, standardized production while impacting the durability, uniqueness, and environmental footprint of handicraft products.

Sustainability and Environmental Impact

Traditional craftsmanship emphasizes sustainable practices by utilizing renewable materials and minimizing waste through meticulous handwork, preserving cultural heritage and reducing environmental impact. Modern manufacturing often relies on mass production techniques that increase resource consumption and generate significant pollution, challenging sustainability goals. Integrating eco-friendly innovations into traditional methods can bridge the gap, promoting environmental responsibility while maintaining artisanal quality.

Quality, Uniqueness, and Mass Production

Traditional craftsmanship emphasizes superior quality and uniqueness through meticulous handwork, resulting in one-of-a-kind pieces with intricate details and cultural significance. Modern manufacturing prioritizes mass production, enabling large-scale output with consistent quality but often sacrificing individuality and artisanal touch. The balance between artisanal heritage and industrial efficiency highlights the trade-off between exclusivity and accessibility in contemporary handicraft markets.

Economic Value: Handmade vs Machine-Made

Traditional craftsmanship generates significant economic value through unique, high-quality handmade products that often command premium prices due to their rarity and artisan skill. Modern manufacturing excels in producing large volumes of machine-made goods at lower costs, driving economies of scale and meeting mass-market demand efficiently. The economic impact of handmade versus machine-made goods varies by consumer preference, market niche, and production scale, influencing price points and profitability.

Preserving Heritage in a Digital Age

Traditional craftsmanship preserves cultural heritage through meticulous handwork and authentic techniques passed down generations, fostering unique artistic expressions. Modern manufacturing leverages digital technology and automation to increase production efficiency and scalability but often risks overshadowing artisanal skills. Integrating digital tools with traditional methods supports heritage preservation while promoting innovation and accessibility in the handicraft industry.

Consumer Preferences and Market Trends

Traditional craftsmanship appeals to consumers seeking authentic, handmade products with unique, artisanal qualities, often valuing sustainability and cultural heritage. Modern manufacturing meets the demand for mass-produced, affordable goods with consistent quality and faster availability, dominating mainstream markets. Market trends indicate a growing niche preference for handcrafted items, driven by consumers' desire for personalized and eco-friendly products despite the convenience of industrial manufacturing.

The Future of Handicrafts: Integration or Competition?

Traditional craftsmanship preserves cultural heritage through artisanal techniques passed down generations, emphasizing quality and uniqueness. Modern manufacturing leverages automation and scalability to meet global demand but often lacks the personalized touch inherent in handicrafts. The future of handicrafts likely involves a hybrid model, integrating digital tools with artisanal skills to enhance creativity while maintaining authenticity.

Traditional Craftsmanship vs Modern Manufacturing Infographic

bizdif.com

bizdif.com