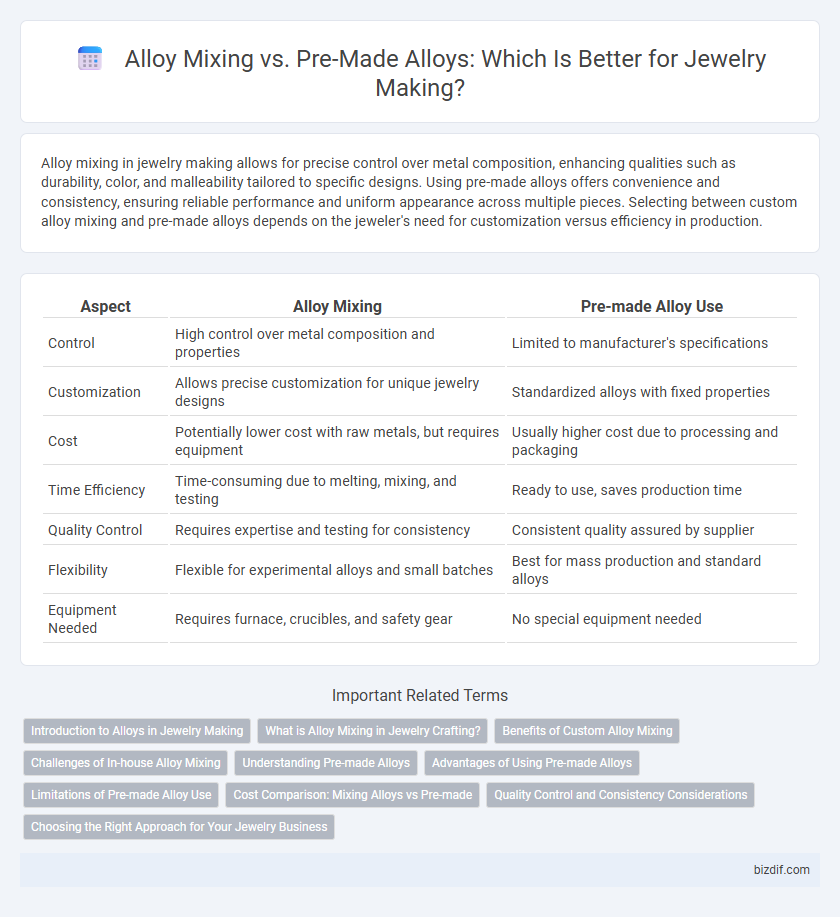

Alloy mixing in jewelry making allows for precise control over metal composition, enhancing qualities such as durability, color, and malleability tailored to specific designs. Using pre-made alloys offers convenience and consistency, ensuring reliable performance and uniform appearance across multiple pieces. Selecting between custom alloy mixing and pre-made alloys depends on the jeweler's need for customization versus efficiency in production.

Table of Comparison

| Aspect | Alloy Mixing | Pre-made Alloy Use |

|---|---|---|

| Control | High control over metal composition and properties | Limited to manufacturer's specifications |

| Customization | Allows precise customization for unique jewelry designs | Standardized alloys with fixed properties |

| Cost | Potentially lower cost with raw metals, but requires equipment | Usually higher cost due to processing and packaging |

| Time Efficiency | Time-consuming due to melting, mixing, and testing | Ready to use, saves production time |

| Quality Control | Requires expertise and testing for consistency | Consistent quality assured by supplier |

| Flexibility | Flexible for experimental alloys and small batches | Best for mass production and standard alloys |

| Equipment Needed | Requires furnace, crucibles, and safety gear | No special equipment needed |

Introduction to Alloys in Jewelry Making

Alloys in jewelry making combine metals like gold, silver, and copper to enhance durability, color, and workability. Mixing alloys on-site allows jewelers to customize metal properties and achieve unique finishes tailored to specific designs. Pre-made alloys offer consistent quality and predictable results, streamlining production for standard jewelry pieces.

What is Alloy Mixing in Jewelry Crafting?

Alloy mixing in jewelry crafting involves combining two or more metals in specific proportions to create a custom metal blend with desired properties such as color, strength, and malleability. This process allows jewelers to tailor alloys for unique finishes and performance characteristics, enhancing the durability and aesthetic appeal of rings, necklaces, and bracelets. Mastery of alloy ratios is crucial for achieving consistent quality and ensuring compatibility with gemstones and other materials in fine jewelry production.

Benefits of Custom Alloy Mixing

Custom alloy mixing in jewelry making allows precise control over metal composition, enhancing properties such as durability, color, and hypoallergenic qualities tailored to specific design needs. This approach promotes cost efficiency by optimizing material use and reducing reliance on expensive pre-made alloys with fixed compositions. Jewelers achieve unique finishes and improved craftsmanship flexibility, resulting in distinctive, high-quality pieces that stand out in the market.

Challenges of In-house Alloy Mixing

In-house alloy mixing in jewelry making presents challenges such as precise control over metal composition and consistency, which can affect the final product's quality and durability. The need for specialized equipment and expertise increases production time and costs, complicating scalability for small workshops. Variability in alloy properties can lead to issues in melting points and workability, creating difficulties in achieving uniform finishes and reliable results compared to pre-made alloys.

Understanding Pre-made Alloys

Pre-made alloys in jewelry making offer consistent composition and predictable performance, simplifying the manufacturing process while ensuring durability and aesthetic appeal. These alloys are often formulated with precise ratios of metals like copper, silver, and gold, enhancing specific properties such as hardness, color, and tarnish resistance. Utilizing pre-made alloys reduces the risk of errors in mixing and allows jewelers to focus on design and craftsmanship without compromising metal quality.

Advantages of Using Pre-made Alloys

Pre-made alloys in jewelry making ensure consistent composition and predictable physical properties, reducing the risk of metal inconsistencies and enhancing overall quality. Using pre-made alloys saves time and labor compared to mixing metals manually, allowing jewelers to focus on design and craftsmanship. These alloys typically undergo controlled manufacturing processes that improve durability, corrosion resistance, and hypoallergenic qualities, making them ideal for high-end and sensitive skin jewelry.

Limitations of Pre-made Alloy Use

Pre-made alloys in jewelry making limit customization options, restricting artisans from precisely controlling metal composition to achieve unique colors, strengths, or hypoallergenic properties. These alloys often contain fixed proportions of metals, reducing flexibility in tailoring alloys for specific design requirements or performance characteristics. Reliance on pre-made alloys can hinder innovation and fine-tuning of jewelry pieces, affecting both aesthetic appeal and durability.

Cost Comparison: Mixing Alloys vs Pre-made

Mixing alloys in jewelry making often reduces material costs by allowing precise control over metal ratios and minimizing waste, but requires investment in raw metals and equipment. Pre-made alloys typically have higher upfront costs due to manufacturing and branding but save time and labor costs during production. Evaluating cost-effectiveness depends on production scale, with alloy mixing favored for custom or small-batch work and pre-made alloys beneficial for large-scale, consistent manufacturing.

Quality Control and Consistency Considerations

Mixing alloys in jewelry making allows precise control over metal composition, ensuring tailored properties for unique designs and enhanced durability. Pre-made alloys offer reliable consistency with industry-standard compositions, reducing variations and simplifying quality control during production processes. Choosing between these options depends on the balance between customization needs and maintaining uniformity for large-scale manufacturing.

Choosing the Right Approach for Your Jewelry Business

Selecting the right approach between alloy mixing and pre-made alloy use depends on your jewelry business's production scale and quality control needs. Alloy mixing offers customization and cost efficiency for bespoke pieces, while pre-made alloys provide consistent quality and time savings for larger batches. Understanding your design goals and workflow will optimize material performance and streamline manufacturing processes.

Alloy Mixing vs Pre-made Alloy Use Infographic

bizdif.com

bizdif.com