Cloisonne enamel involves creating delicate compartments using thin metal wires to hold the enamel in place, resulting in intricate and colorful designs. Champleve enamel requires carving or etching recesses directly into the metal surface before filling them with enamel, producing a textured and durable finish. Both techniques showcase vibrant enamel artistry but differ in the method of enamel application and surface detailing.

Table of Comparison

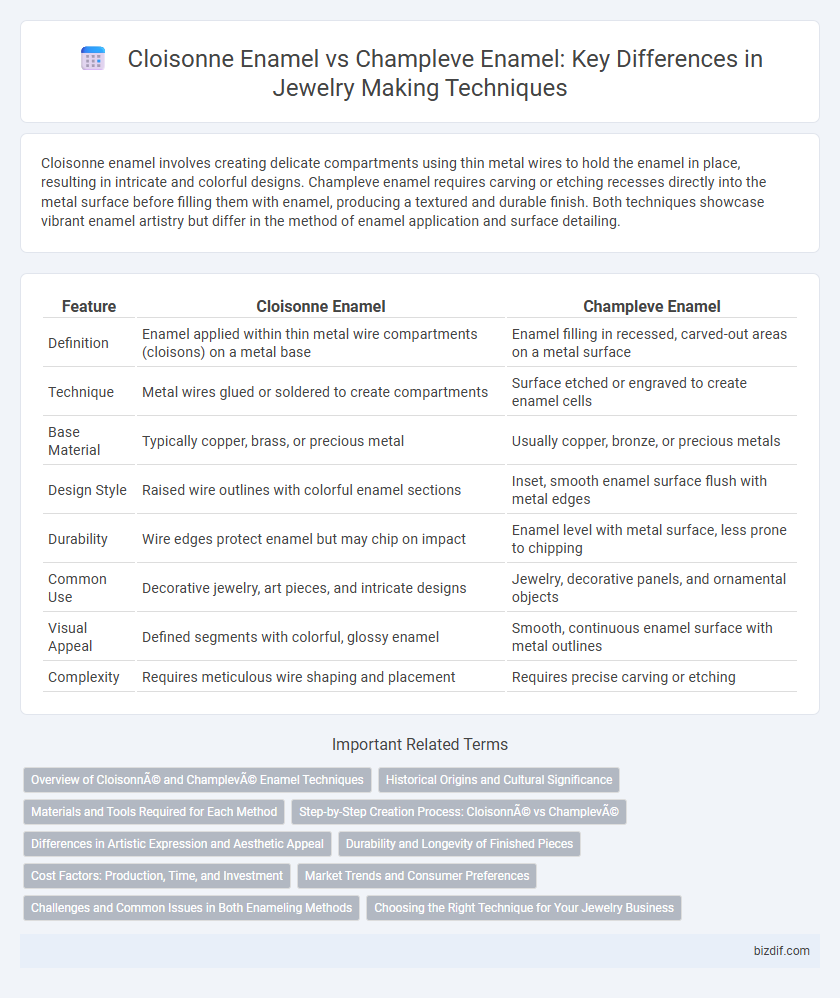

| Feature | Cloisonne Enamel | Champleve Enamel |

|---|---|---|

| Definition | Enamel applied within thin metal wire compartments (cloisons) on a metal base | Enamel filling in recessed, carved-out areas on a metal surface |

| Technique | Metal wires glued or soldered to create compartments | Surface etched or engraved to create enamel cells |

| Base Material | Typically copper, brass, or precious metal | Usually copper, bronze, or precious metals |

| Design Style | Raised wire outlines with colorful enamel sections | Inset, smooth enamel surface flush with metal edges |

| Durability | Wire edges protect enamel but may chip on impact | Enamel level with metal surface, less prone to chipping |

| Common Use | Decorative jewelry, art pieces, and intricate designs | Jewelry, decorative panels, and ornamental objects |

| Visual Appeal | Defined segments with colorful, glossy enamel | Smooth, continuous enamel surface with metal outlines |

| Complexity | Requires meticulous wire shaping and placement | Requires precise carving or etching |

Overview of Cloisonné and Champlevé Enamel Techniques

Cloisonne enamel involves creating intricate designs by soldering thin metal wires onto a metal base to form compartments filled with enamel, producing vibrant, detailed patterns commonly seen in jewelry and decorative art. Champleve enamel is characterized by carving or etching recessed areas directly into a metal surface, which are then filled with enamel and fired, resulting in a textured, flush finish often used in antique and artisanal jewelry. Both techniques require precise kiln firing to fuse the enamel, but Cloisonne emphasizes wirework outlines while Champleve focuses on engraved cavities for enamel placement.

Historical Origins and Cultural Significance

Cloisonne enamel, originating in the Byzantine Empire around the 6th century, is characterized by its intricate wire partitions that create vibrant, detailed designs symbolizing spiritual and imperial power. Champleve enamel, with origins tracing back to ancient Celtic and Roman cultures, involves carving recessed cells into metal surfaces filled with enamel, reflecting a more robust and earthy aesthetic often linked to medieval European religious artifacts. Both techniques hold significant cultural value, showcasing the evolution of enamel artistry in different regions and historical periods.

Materials and Tools Required for Each Method

Cloisonne enamel requires fine metal wires, typically made of gold, silver, or copper, to create compartments (cloisons) on a metal base, with enamel powders applied within these thin partitions. Tools for cloisonne include pliers for bending wires, adhesive for securing cloisons, and kilns essential for firing and melting the enamel to achieve vibrant color and smooth surfaces. Champleve enamel, on the other hand, involves carving or etching recessed areas directly into a metal surface, usually copper or bronze, followed by filling these cavities with enamel; tools needed include engraving tools, chisels, and burnishers alongside the kiln for enamel firing.

Step-by-Step Creation Process: Cloisonné vs Champlevé

Cloisonne enamel involves creating intricate designs by soldering fine metal wires (usually gold or copper) onto a metal base, forming compartments filled with enamel powder before firing. Champleve enamel requires engraving or etching recesses directly into the metal surface, which are then filled with enamel and fired to produce a smooth, flush finish. The key distinction lies in cloisonne's wire partitions shaping the design, while champleve relies on carved openings in the metal itself.

Differences in Artistic Expression and Aesthetic Appeal

Cloisonne enamel features delicate metal wire partitions creating intricate, raised patterns filled with vibrant enamel colors, resulting in a polished, jewel-like surface with vivid details. Champleve enamel involves carving recessed cells directly into the metal surface, which are then filled with enamel, producing a textured, robust look with more pronounced metal edges visible between enamel sections. The distinct techniques offer contrasting artistic expressions--Cloisonne emphasizes fine, precise outlines and smooth finish, while Champleve showcases bold, textured designs with a tactile, sculptural quality.

Durability and Longevity of Finished Pieces

Cloisonne enamel features metal wire compartments that securely hold glass enamel, resulting in highly durable and chip-resistant jewelry pieces. Champleve enamel involves carving recessed areas into the metal surface, which can be more prone to wear and chipping over time due to its thinner enamel layers. The sturdiness of cloisonne often ensures longer-lasting vibrancy and structural integrity compared to champleve, making it a preferred choice for heirloom-quality jewelry.

Cost Factors: Production, Time, and Investment

Cloisonne enamel typically demands higher production costs due to the intricate process of creating fine metal partitions (cloisons) that separate each colored enamel section, requiring skilled craftsmanship and longer labor time. Champleve enamel involves carving or etching recessed areas directly into the metal base, which is generally faster and less labor-intensive, resulting in lower time investment and production expenses. Investment in specialized tools and skill training is higher for Cloisonne, impacting overall cost factors compared to the more straightforward and time-efficient Champleve enamel technique.

Market Trends and Consumer Preferences

Cloisonne enamel jewelry continues to captivate the luxury market with its intricate wirework and vibrant colors, appealing to consumers seeking artisanal craftsmanship and historical elegance. In contrast, Champleve enamel gains traction for its durability and bold, recessed designs, favored among younger buyers and contemporary designers prioritizing modern aesthetics. Market trends indicate a growing demand for personalized and sustainable pieces, driving innovation in both techniques to incorporate eco-friendly materials and customizable options.

Challenges and Common Issues in Both Enameling Methods

Cloisonne enamel often faces challenges with wire displacement and uneven enamel filling, which can cause cracking or color inconsistencies during firing. Champleve enamel frequently encounters difficulties in achieving uniform depth in etched or engraved cells, leading to enamel pooling or inconsistent surface texture. Both methods require precise temperature control and careful handling to prevent flaws such as bubbling, discoloration, or insufficient adhesion.

Choosing the Right Technique for Your Jewelry Business

Choosing between cloisonne enamel and champleve enamel depends on the desired aesthetic and production scale in your jewelry business. Cloisonne enamel offers intricate, colorful designs created by filling thin metal partitions with enamel, ideal for detailed and vibrant pieces. Champleve enamel involves carving recesses into the metal surface to fill with enamel, providing a more textured, durable finish suited for larger, robust jewelry items.

Cloisonné enamel vs Champlevé enamel Infographic

bizdif.com

bizdif.com