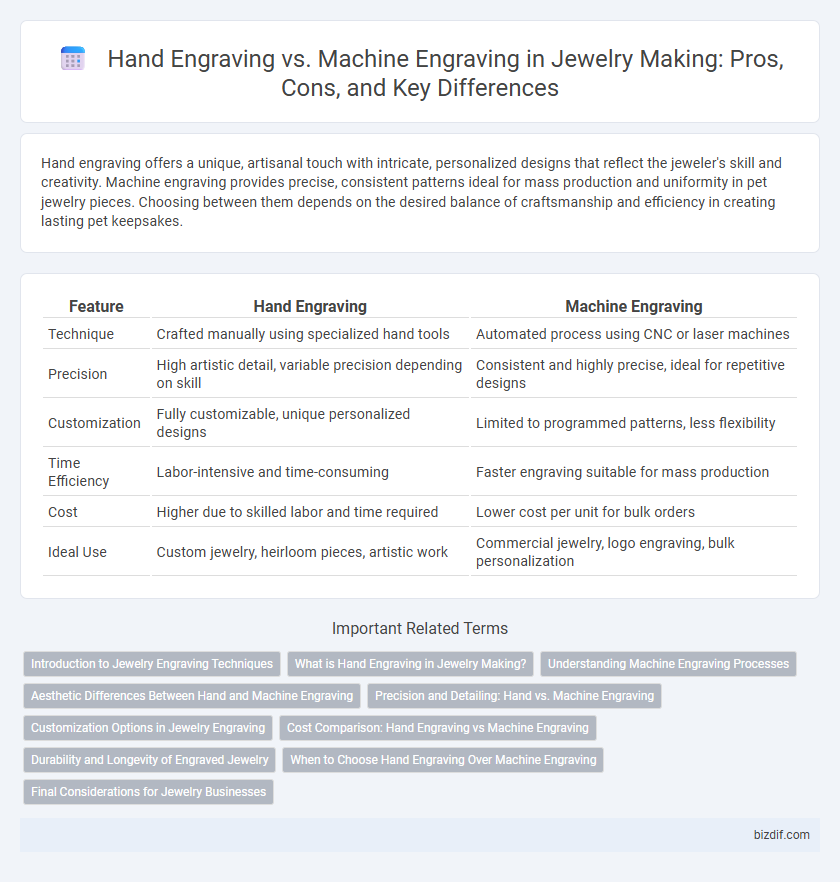

Hand engraving offers a unique, artisanal touch with intricate, personalized designs that reflect the jeweler's skill and creativity. Machine engraving provides precise, consistent patterns ideal for mass production and uniformity in pet jewelry pieces. Choosing between them depends on the desired balance of craftsmanship and efficiency in creating lasting pet keepsakes.

Table of Comparison

| Feature | Hand Engraving | Machine Engraving |

|---|---|---|

| Technique | Crafted manually using specialized hand tools | Automated process using CNC or laser machines |

| Precision | High artistic detail, variable precision depending on skill | Consistent and highly precise, ideal for repetitive designs |

| Customization | Fully customizable, unique personalized designs | Limited to programmed patterns, less flexibility |

| Time Efficiency | Labor-intensive and time-consuming | Faster engraving suitable for mass production |

| Cost | Higher due to skilled labor and time required | Lower cost per unit for bulk orders |

| Ideal Use | Custom jewelry, heirloom pieces, artistic work | Commercial jewelry, logo engraving, bulk personalization |

Introduction to Jewelry Engraving Techniques

Hand engraving in jewelry involves artisans using specialized tools to carve intricate designs directly onto metal surfaces, offering unmatched detail and personalized craftsmanship. Machine engraving employs computerized technology to etch precise and consistent patterns quickly, ideal for large-scale production and uniformity. Both techniques enhance jewelry aesthetics, with hand engraving emphasizing artisanal uniqueness and machine engraving prioritizing efficiency and repeatability.

What is Hand Engraving in Jewelry Making?

Hand engraving in jewelry making involves meticulously carving intricate designs directly onto metal surfaces using specialized tools like gravers. This traditional technique allows for unique, personalized details and depth that machines often cannot replicate. Skilled artisans achieve exceptional precision and artistry, enhancing the value and aesthetic appeal of each piece.

Understanding Machine Engraving Processes

Machine engraving in jewelry making utilizes advanced computer numerical control (CNC) technology to achieve precise and consistent designs on metals such as gold, silver, and platinum. This process allows for high-speed production with intricate detailing that maintains uniformity across multiple pieces, making it ideal for commercial-scale manufacturing. Compared to hand engraving, machine engraving offers scalability and repeatability while integrating digital design files for customizable patterns.

Aesthetic Differences Between Hand and Machine Engraving

Hand engraving offers unique, intricate patterns with subtle variations that reflect the artisan's skill, creating a personalized and organic aesthetic on each piece. Machine engraving produces precise, uniform designs, ensuring consistency and clean lines ideal for detailed and repetitive patterns. The choice between hand and machine engraving significantly influences the visual impact and perceived craftsmanship of jewelry.

Precision and Detailing: Hand vs. Machine Engraving

Hand engraving offers unparalleled precision and intricate detailing due to the artisan's skill, allowing for unique, customized designs that reflect fine craftsmanship. Machine engraving provides consistent depth and uniformity, suitable for mass production with high accuracy but may lack the subtle nuances seen in hand-engraved pieces. The choice between hand and machine engraving depends on the desired balance between artistic individuality and efficiency in jewelry making.

Customization Options in Jewelry Engraving

Hand engraving offers unparalleled customization options in jewelry engraving, allowing artisans to create intricate, unique designs tailored to individual preferences with exceptional depth and texture. Machine engraving provides precision and consistency, ideal for mass production but limited in complexity and personalization compared to hand craftsmanship. Personalized jewelry benefits significantly from hand engraving, as it delivers a distinctive, one-of-a-kind finish that machines cannot replicate.

Cost Comparison: Hand Engraving vs Machine Engraving

Hand engraving typically incurs higher costs due to the skilled craftsmanship and time-intensive process involved, with prices ranging from $50 to $150 per hour. Machine engraving offers a more affordable alternative, averaging $20 to $60 per hour, thanks to faster production and reduced labor. Choosing between hand and machine engraving depends on budget constraints and the desired level of detail and personalization.

Durability and Longevity of Engraved Jewelry

Hand engraving creates deep, precise grooves that enhance the durability and longevity of jewelry engravings by resisting wear and retaining fine details over time. Machine engraving, while efficient, often produces shallower marks that may fade or wear down more quickly with regular use. Choosing hand engraving ensures a timeless, resilient design that maintains its clarity even after years of exposure to daily wear.

When to Choose Hand Engraving Over Machine Engraving

Hand engraving is ideal for custom, intricate designs where unique artistry and depth are essential, offering a personal touch that machines cannot replicate. It is preferred for heirloom pieces, luxury jewelry, and projects requiring subtle texture variations or delicate detailing. Choose hand engraving when authenticity, craftsmanship, and one-of-a-kind character are the priorities over speed and uniformity.

Final Considerations for Jewelry Businesses

Hand engraving offers unparalleled artisanal detail and uniqueness, enhancing the perceived value of custom jewelry pieces. Machine engraving provides consistent precision and faster turnaround, ideal for high-volume production and standardized designs. Jewelry businesses should balance craftsmanship appeal with efficiency demands to meet diverse customer preferences and scale effectively.

Hand Engraving vs Machine Engraving Infographic

bizdif.com

bizdif.com