Benchwork in jewelry making emphasizes hands-on craftsmanship, allowing artisans to create unique, intricate pieces through techniques like soldering, filing, and stone setting. CAD design leverages computer software to produce precise, detailed 3D models that streamline the production process and enable complex geometries impossible by hand. Combining benchwork with CAD design enhances creativity and efficiency, resulting in high-quality, customized jewelry.

Table of Comparison

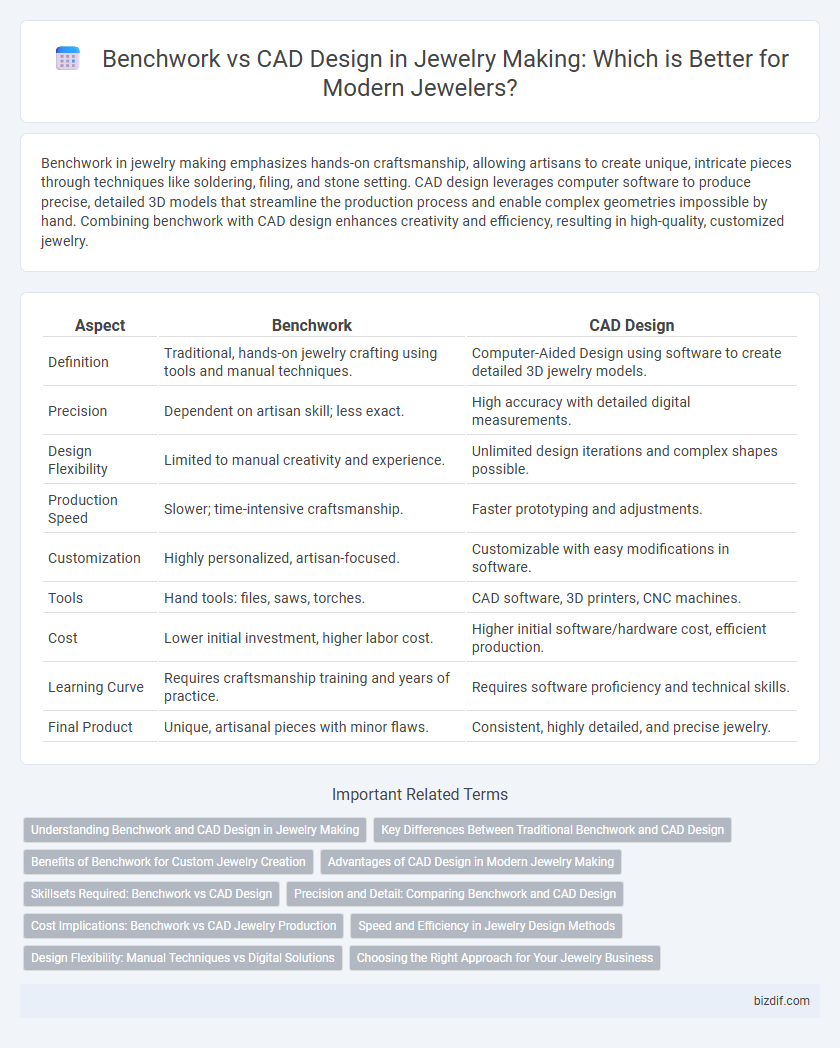

| Aspect | Benchwork | CAD Design |

|---|---|---|

| Definition | Traditional, hands-on jewelry crafting using tools and manual techniques. | Computer-Aided Design using software to create detailed 3D jewelry models. |

| Precision | Dependent on artisan skill; less exact. | High accuracy with detailed digital measurements. |

| Design Flexibility | Limited to manual creativity and experience. | Unlimited design iterations and complex shapes possible. |

| Production Speed | Slower; time-intensive craftsmanship. | Faster prototyping and adjustments. |

| Customization | Highly personalized, artisan-focused. | Customizable with easy modifications in software. |

| Tools | Hand tools: files, saws, torches. | CAD software, 3D printers, CNC machines. |

| Cost | Lower initial investment, higher labor cost. | Higher initial software/hardware cost, efficient production. |

| Learning Curve | Requires craftsmanship training and years of practice. | Requires software proficiency and technical skills. |

| Final Product | Unique, artisanal pieces with minor flaws. | Consistent, highly detailed, and precise jewelry. |

Understanding Benchwork and CAD Design in Jewelry Making

Benchwork in jewelry making involves hands-on techniques such as sawing, filing, soldering, and stone setting, allowing artisans to create intricate, custom pieces with tactile precision. CAD design uses specialized software to create detailed 3D models, enabling designers to visualize and modify jewelry concepts digitally before manufacturing, enhancing accuracy and efficiency. Combining benchwork skills with CAD technology offers jewelers greater flexibility, blending traditional craftsmanship with modern innovation for superior design outcomes.

Key Differences Between Traditional Benchwork and CAD Design

Traditional benchwork in jewelry making relies heavily on manual skills such as sawing, filing, and soldering to sculpt and assemble pieces, emphasizing tactile craftsmanship. CAD design utilizes computer software to create precise 3D models, allowing for intricate detailing, easy modifications, and rapid prototyping. While benchwork offers a hands-on artisanal approach, CAD design enhances accuracy, repeatability, and integration with 3D printing technology.

Benefits of Benchwork for Custom Jewelry Creation

Benchwork allows jewelers to apply intricate hand-tool techniques, resulting in unique, highly personalized custom jewelry pieces with exceptional detail. This hands-on approach enhances creative control and enables real-time adjustments to design, ensuring an exact fit and finish tailored to client specifications. The tactile feedback during benchwork also improves the quality and durability of the final piece compared to purely digital CAD designs.

Advantages of CAD Design in Modern Jewelry Making

CAD design in modern jewelry making offers unparalleled precision and allows intricate designs that are difficult to achieve through traditional benchwork. It streamlines the prototyping process by enabling quick modifications and virtual visualization, reducing material waste and production time. Advanced software integration supports customization and complex geometries, enhancing creativity and efficiency in jewelry manufacturing.

Skillsets Required: Benchwork vs CAD Design

Benchwork in jewelry making demands hands-on skills such as precise metal shaping, soldering, stone setting, and polishing, requiring a keen eye for detail and steady hand coordination. CAD design relies heavily on technical proficiency in software like Rhino, Matrix, or JewelCAD, combined with spatial visualization and digital rendering capabilities to create accurate, customizable 3D models. Mastery in benchwork emphasizes traditional craftsmanship, while CAD design prioritizes digital innovation and precision engineering skills.

Precision and Detail: Comparing Benchwork and CAD Design

Benchwork in jewelry making offers hands-on precision, allowing artisans to manipulate metals and gemstones with tactile feedback crucial for intricate detailing. CAD design provides unmatched accuracy through computer-aided tools that enable exact measurements, complex geometries, and repeatable designs at the digital level. Combining benchwork with CAD enhances precision and fine detail, blending traditional craftsmanship with modern technology for superior quality jewelry production.

Cost Implications: Benchwork vs CAD Jewelry Production

Benchwork jewelry production typically involves higher labor costs due to the time-intensive handcrafting process, while CAD design reduces manual labor by streamlining the creation phase through digital modeling. Material waste is generally lower with CAD, as virtual prototypes minimize errors and allow precise adjustments before manufacturing. Initial investment in CAD software and equipment can be significant, but long-term savings arise from increased efficiency and scalability compared to traditional benchwork methods.

Speed and Efficiency in Jewelry Design Methods

Benchwork offers hands-on precision and immediate adjustments, enabling jewelers to quickly prototype and refine designs through manual manipulation. CAD design accelerates the creation process by allowing complex patterns to be drafted, modified, and replicated digitally with high accuracy and minimal material waste. Combining benchwork with CAD methods enhances overall efficiency, balancing creative flexibility with streamlined production timelines.

Design Flexibility: Manual Techniques vs Digital Solutions

Manual benchwork in jewelry making offers unparalleled tactile control and nuanced design flexibility, allowing artisans to manipulate metals and gemstones with precision and spontaneity. CAD design, on the other hand, provides advanced customization options through digital modeling software, enabling intricate patterns and consistent replication unattainable by hand. Combining both methods maximizes creative potential, blending hands-on craftsmanship with precise digital innovation.

Choosing the Right Approach for Your Jewelry Business

Selecting between benchwork and CAD design depends on the scale and precision required by your jewelry business; benchwork offers hands-on craftsmanship ideal for unique, custom pieces, while CAD design ensures high precision and efficiency for complex or bulk production. Integrating CAD technology can streamline workflows and reduce errors, enhancing design flexibility with 3D modeling capabilities. Prioritize your business goals, client preferences, and production volume to determine the optimal balance between traditional artistry and modern digital techniques.

Benchwork vs Cad Design Infographic

bizdif.com

bizdif.com