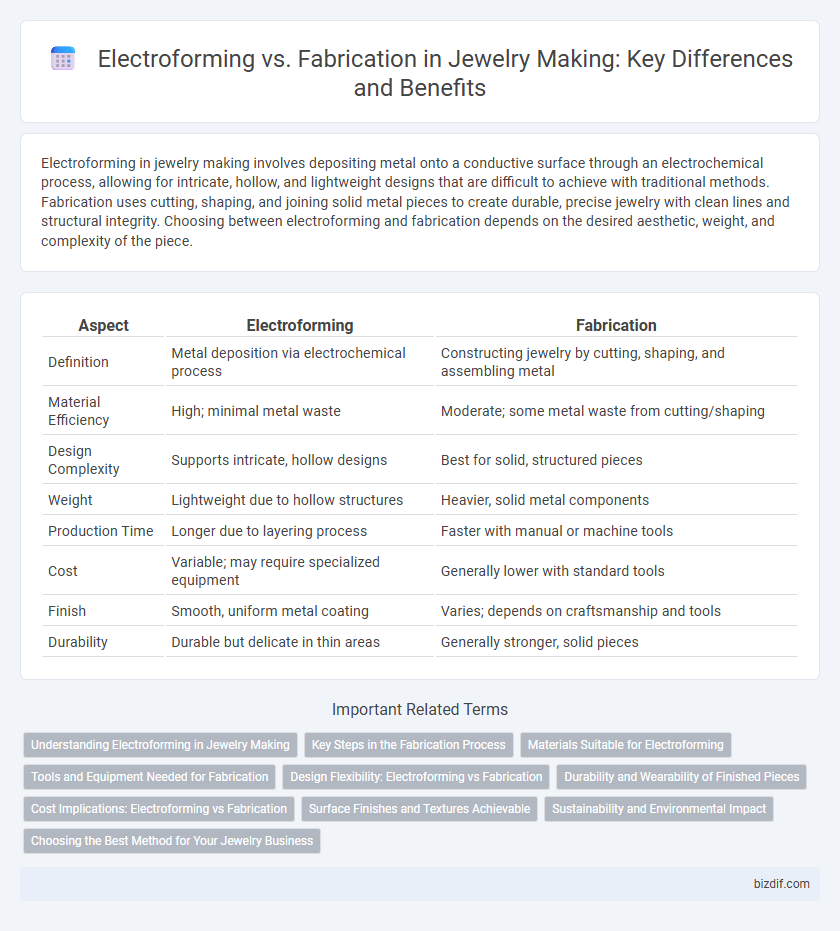

Electroforming in jewelry making involves depositing metal onto a conductive surface through an electrochemical process, allowing for intricate, hollow, and lightweight designs that are difficult to achieve with traditional methods. Fabrication uses cutting, shaping, and joining solid metal pieces to create durable, precise jewelry with clean lines and structural integrity. Choosing between electroforming and fabrication depends on the desired aesthetic, weight, and complexity of the piece.

Table of Comparison

| Aspect | Electroforming | Fabrication |

|---|---|---|

| Definition | Metal deposition via electrochemical process | Constructing jewelry by cutting, shaping, and assembling metal |

| Material Efficiency | High; minimal metal waste | Moderate; some metal waste from cutting/shaping |

| Design Complexity | Supports intricate, hollow designs | Best for solid, structured pieces |

| Weight | Lightweight due to hollow structures | Heavier, solid metal components |

| Production Time | Longer due to layering process | Faster with manual or machine tools |

| Cost | Variable; may require specialized equipment | Generally lower with standard tools |

| Finish | Smooth, uniform metal coating | Varies; depends on craftsmanship and tools |

| Durability | Durable but delicate in thin areas | Generally stronger, solid pieces |

Understanding Electroforming in Jewelry Making

Electroforming in jewelry making is a process that uses electrical currents to deposit metal onto a conductive surface, creating lightweight, detailed, and hollow pieces that are difficult to achieve with traditional fabrication. Unlike fabrication, which involves cutting, shaping, and soldering solid metals, electroforming allows for complex, organic shapes with thinner walls and intricate textures. This technique enhances design possibilities and reduces material costs while maintaining durability and aesthetic appeal in finished jewelry.

Key Steps in the Fabrication Process

Key steps in the fabrication process of jewelry include designing a precise blueprint, selecting quality metals like sterling silver or gold, and cutting or shaping the metal sheets or wires using tools such as saws and torches. Soldering follows, where components are joined by melting a filler metal to create strong joints, often requiring flux to prevent oxidation. Final steps involve polishing, finishing, and sometimes stone setting to ensure both durability and aesthetic appeal.

Materials Suitable for Electroforming

Copper, brass, and silver are the primary metals suitable for electroforming due to their conductivity and durability, making them ideal for creating detailed and lightweight jewelry pieces. Unlike traditional fabrication, which can involve a variety of metals including gold and platinum, electroforming relies heavily on metals that can easily adhere and build up in layers through the electrochemical process. This method allows jewelers to craft intricate shapes that would be difficult or time-consuming to achieve through conventional fabrication techniques.

Tools and Equipment Needed for Fabrication

Fabrication in jewelry making requires essential tools such as saw frames, files, soldering equipment, and metal hammers to shape and join metals precisely. Unlike electroforming, which relies heavily on plating tanks and power supplies, fabrication demands manual instruments and workbenches for cutting, bending, and assembling components. Mastery of these traditional tools enables jewelers to create intricate, durable pieces through direct manipulation of metal.

Design Flexibility: Electroforming vs Fabrication

Electroforming offers unparalleled design flexibility by allowing intricate, hollow, and lightweight jewelry pieces that traditional fabrication struggles to achieve. Fabrication, while excelling in precision and durability for solid structures, can be limited by the manual skills required and the complexity of metal shaping. Electroforming enables creative freedom for elaborate textures and organic shapes, expanding design possibilities beyond conventional metalworking techniques.

Durability and Wearability of Finished Pieces

Electroforming produces jewelry with enhanced durability by depositing a thick layer of metal onto a base, creating lightweight yet strong pieces resistant to tarnish and deformation. In contrast, traditional fabrication relies on mechanical joining and soldering, which may result in weaker joints over time and heavier finished items. Wearability favors electroformed jewelry due to its lighter weight and smooth surfaces, offering comfort without compromising structural integrity.

Cost Implications: Electroforming vs Fabrication

Electroforming offers cost advantages through reduced material waste and the ability to create lightweight, intricate jewelry without expensive metals. Traditional fabrication often requires more raw materials and labor-intensive processes, leading to higher overall production costs. Choosing electroforming can significantly lower expenses for complex designs while fabrication remains cost-effective for simpler, sturdy pieces.

Surface Finishes and Textures Achievable

Electroforming in jewelry making allows for intricate, organic surface textures with smooth, uniform finishes due to the metal deposition process over a conductive mold. Fabrication offers greater control over precise surface finishes and sharp, defined textures by manually cutting, soldering, and shaping metal sheets. Both techniques enable unique aesthetic effects, but electroforming excels in creating delicate, naturalistic textures, while fabrication emphasizes structural detail and clean lines.

Sustainability and Environmental Impact

Electroforming uses less raw metal by depositing thin layers of metal onto a base, significantly reducing material waste compared to traditional fabrication, which often involves cutting and soldering thick metal sheets. This process lowers energy consumption and minimizes the use of chemical solvents, contributing to a smaller environmental footprint. Fabrication's reliance on metals sourced through mining often entails higher ecological disruption, making electroforming a more sustainable choice in jewelry production.

Choosing the Best Method for Your Jewelry Business

Electroforming allows jewelers to create lightweight, intricate designs by depositing metal onto a conductive surface, ideal for complex shapes and fine details. Fabrication relies on traditional techniques like cutting, soldering, and assembling metal pieces, offering durability and control over structural integrity. Choosing between electroforming and fabrication depends on your business priorities, such as design complexity, production volume, material costs, and desired finish quality.

Electroforming vs fabrication Infographic

bizdif.com

bizdif.com