In-house manufacturing offers jewelry makers complete control over design, quality, and production timelines, enabling customization and rapid adjustments. Outsourcing can reduce operational costs and provide access to specialized craftsmanship or advanced technology not available internally. Balancing these approaches depends on budget constraints, production volume, and the desired level of quality assurance in the final jewelry pieces.

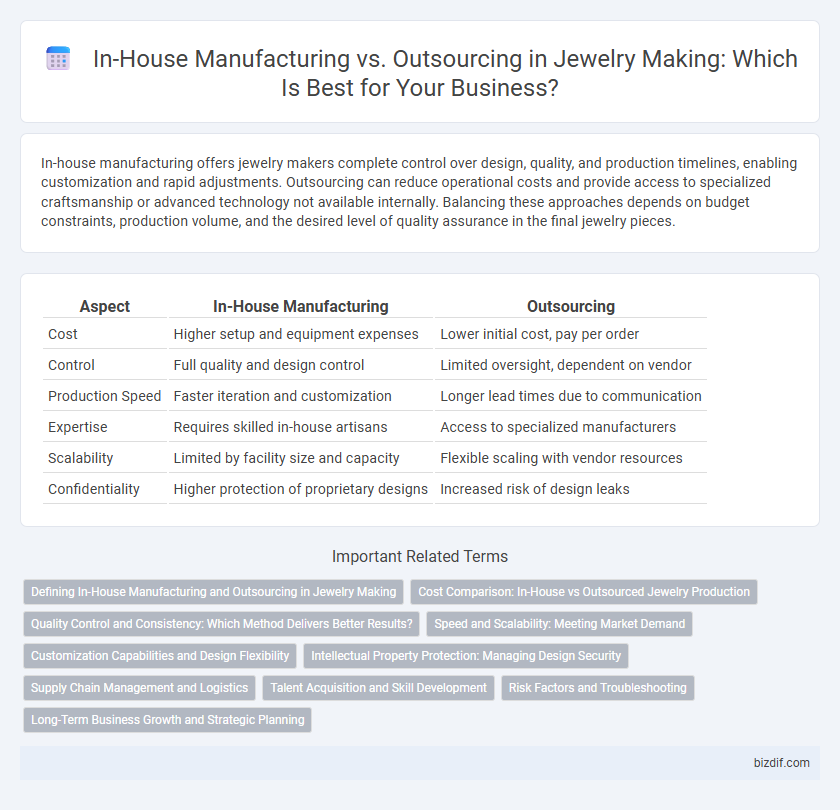

Table of Comparison

| Aspect | In-House Manufacturing | Outsourcing |

|---|---|---|

| Cost | Higher setup and equipment expenses | Lower initial cost, pay per order |

| Control | Full quality and design control | Limited oversight, dependent on vendor |

| Production Speed | Faster iteration and customization | Longer lead times due to communication |

| Expertise | Requires skilled in-house artisans | Access to specialized manufacturers |

| Scalability | Limited by facility size and capacity | Flexible scaling with vendor resources |

| Confidentiality | Higher protection of proprietary designs | Increased risk of design leaks |

Defining In-House Manufacturing and Outsourcing in Jewelry Making

In-house manufacturing in jewelry making involves the complete production process conducted within the company's own facilities, allowing for direct control over design, quality, and materials. Outsourcing, by contrast, entails contracting external specialists or factories to handle aspects of production, often to reduce costs or access specialized skills. Each approach influences lead time, cost structure, and customization capabilities differently in the jewelry industry.

Cost Comparison: In-House vs Outsourced Jewelry Production

In-house jewelry manufacturing typically incurs higher fixed costs due to investments in specialized equipment, skilled labor, and facility maintenance, but offers greater control over quality and customization. Outsourcing jewelry production often reduces upfront expenses and operational overhead by leveraging external suppliers' economies of scale, though it may involve variable costs and potential risks in quality consistency and lead times. Cost comparison between in-house and outsourced production depends heavily on order volume, complexity of designs, and desired turnaround time, making thorough cost-benefit analysis critical for optimizing profit margins.

Quality Control and Consistency: Which Method Delivers Better Results?

In-house manufacturing offers superior quality control and consistency due to direct oversight of every production stage, allowing for immediate adjustments and adherence to strict standards. Outsourcing can introduce variability in craftsmanship and materials, as suppliers may have differing quality protocols and less frequent communication. Therefore, for jewelry makers prioritizing precision and uniformity, in-house production typically delivers better results and ensures higher customer satisfaction.

Speed and Scalability: Meeting Market Demand

In-house manufacturing in jewelry making offers faster turnaround times and direct control over production, enabling quick adjustments to design and volume to meet market demand. Outsourcing provides scalability by leveraging specialized facilities with larger capacity, ideal for fulfilling bulk orders or seasonal spikes. Choosing between the two depends on balancing speed requirements with the ability to scale production efficiently.

Customization Capabilities and Design Flexibility

In-house manufacturing in jewelry making ensures superior customization capabilities, allowing artisans to tailor designs precisely to client specifications with full control over materials and craftsmanship. This approach offers unparalleled design flexibility, enabling rapid adjustments and unique, intricate creations that reflect personal style. Outsourcing, while often cost-effective, limits these options due to standardized production processes and reduced direct oversight on bespoke details.

Intellectual Property Protection: Managing Design Security

In-house manufacturing in jewelry making ensures robust intellectual property protection by maintaining strict control over design confidentiality and reducing the risk of unauthorized reproduction. Outsourcing can expose unique designs to third-party vendors, increasing vulnerabilities to IP theft unless stringent contractual agreements and non-disclosure measures are enforced. Prioritizing secure workflows and access limitations within in-house processes strengthens design security and preserves competitive advantages.

Supply Chain Management and Logistics

In-house manufacturing in jewelry making enables tighter control over supply chain management, ensuring quality consistency and faster turnaround times by directly overseeing material sourcing and production schedules. Outsourcing can reduce operational costs and provide access to specialized craftsmanship but introduces complexities in logistics coordination, longer lead times, and potential risks in inventory management. Efficient supply chain integration requires balancing manufacturing control with the scalability and flexibility that outsourcing logistics can offer, optimizing delivery accuracy and minimizing production delays.

Talent Acquisition and Skill Development

In-house manufacturing in jewelry making enables direct control over talent acquisition, allowing brands to cultivate specialized skills and foster continuous skill development tailored to their unique designs and quality standards. Outsourcing often limits access to skilled artisans and impedes personalized training, potentially affecting craftsmanship consistency and innovation. Investing in an in-house team enhances mastery of advanced techniques, ensuring superior product quality and reinforcing brand value in a competitive market.

Risk Factors and Troubleshooting

In-house manufacturing of jewelry allows direct control over quality and reduces risks related to supply chain disruptions, but it requires substantial investment in skilled labor and equipment maintenance. Outsourcing can lower operational costs and provide access to specialized craftsmanship, yet it introduces risks such as delayed deliveries, inconsistent product quality, and intellectual property vulnerabilities. Effective troubleshooting involves diligent supplier screening, clear communication protocols, and contingency plans to mitigate production delays or defects.

Long-Term Business Growth and Strategic Planning

In-house manufacturing in jewelry making ensures greater control over quality, fosters innovation, and enables faster response to market trends, directly supporting sustainable long-term business growth. Outsourcing can reduce immediate costs but may compromise customization, lead times, and supply chain reliability, potentially hindering strategic agility. Prioritizing in-house capabilities aligns with strategic planning focused on brand differentiation and scalability in a competitive luxury market.

In-House Manufacturing vs Outsourcing Infographic

bizdif.com

bizdif.com