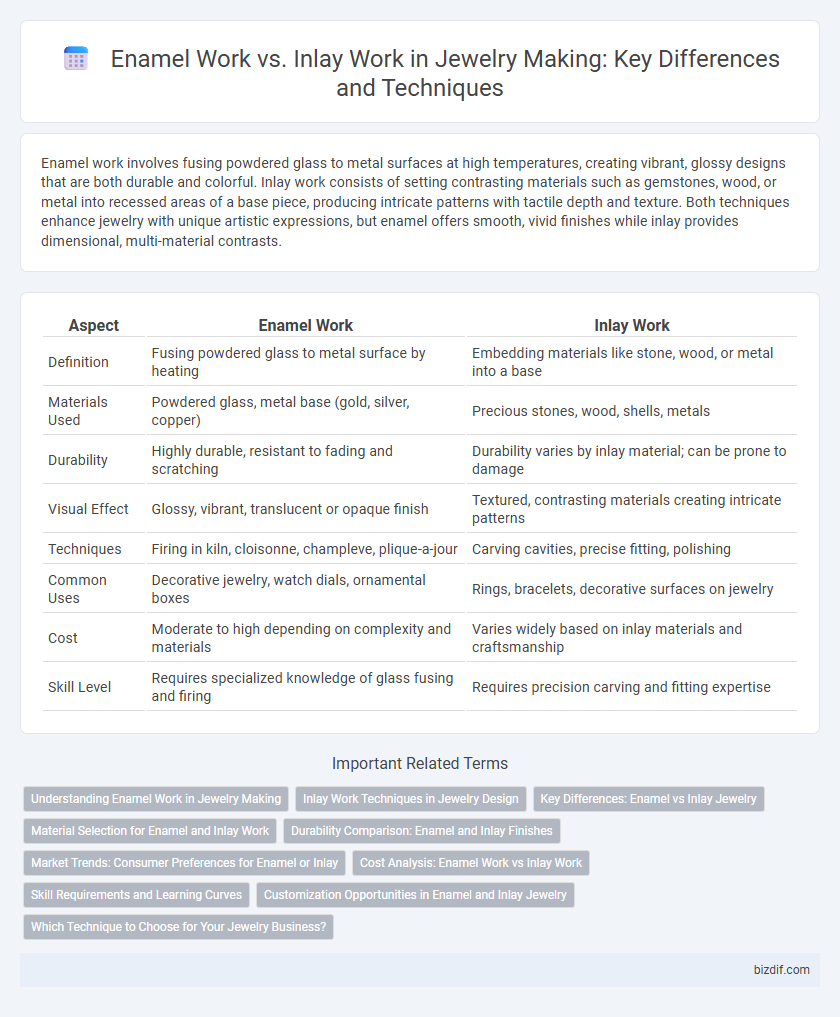

Enamel work involves fusing powdered glass to metal surfaces at high temperatures, creating vibrant, glossy designs that are both durable and colorful. Inlay work consists of setting contrasting materials such as gemstones, wood, or metal into recessed areas of a base piece, producing intricate patterns with tactile depth and texture. Both techniques enhance jewelry with unique artistic expressions, but enamel offers smooth, vivid finishes while inlay provides dimensional, multi-material contrasts.

Table of Comparison

| Aspect | Enamel Work | Inlay Work |

|---|---|---|

| Definition | Fusing powdered glass to metal surface by heating | Embedding materials like stone, wood, or metal into a base |

| Materials Used | Powdered glass, metal base (gold, silver, copper) | Precious stones, wood, shells, metals |

| Durability | Highly durable, resistant to fading and scratching | Durability varies by inlay material; can be prone to damage |

| Visual Effect | Glossy, vibrant, translucent or opaque finish | Textured, contrasting materials creating intricate patterns |

| Techniques | Firing in kiln, cloisonne, champleve, plique-a-jour | Carving cavities, precise fitting, polishing |

| Common Uses | Decorative jewelry, watch dials, ornamental boxes | Rings, bracelets, decorative surfaces on jewelry |

| Cost | Moderate to high depending on complexity and materials | Varies widely based on inlay materials and craftsmanship |

| Skill Level | Requires specialized knowledge of glass fusing and firing | Requires precision carving and fitting expertise |

Understanding Enamel Work in Jewelry Making

Enamel work in jewelry making involves fusing powdered glass to metal surfaces through high-temperature firing, creating vibrant and durable decorative coatings. This technique allows for intricate color patterns and a glossy finish that enhances the visual appeal of pieces such as pendants, rings, and brooches. Unlike inlay work, which embeds materials like stones or metals into recessed areas, enamel work relies on a chemical fusion process to bond color directly onto the metal substrate.

Inlay Work Techniques in Jewelry Design

Inlay work techniques in jewelry design involve embedding pieces of materials such as gemstones, wood, or metals into a base metal surface to create intricate patterns and textures. This method offers a durable and visually striking alternative to enamel work by allowing the use of diverse materials like turquoise, opal, and mother-of-pearl for customizable artistic expressions. Precision cutting and careful fitting are essential in inlay work to ensure a seamless and polished finish that enhances the overall aesthetic and value of the jewelry piece.

Key Differences: Enamel vs Inlay Jewelry

Enamel work in jewelry involves fusing powdered glass to a metal surface through high-temperature firing, creating a smooth, glossy coating that offers vibrant color and durability. Inlay work, on the other hand, consists of embedding materials such as gemstones, metal, or wood into cavities carved into the jewelry base, emphasizing texture and intricate patterns. The key differences lie in enamel's reliance on fusing techniques for color application versus inlay's physical insertion of decorative elements into the metal substrate.

Material Selection for Enamel and Inlay Work

Enamel work in jewelry making requires materials with high thermal resistance, such as copper, silver, and gold, to withstand firing temperatures between 1400degF and 1600degF without warping or melting. Inlay work demands the use of durable base metals like brass or stainless steel combined with inlay materials such as precious stones, wood, or mother-of-pearl, which are carefully set into cavities and do not endure high heat. Choosing the correct material is critical to ensure the integrity and longevity of enamel pieces subjected to heat and the precise fit and finish in inlay designs.

Durability Comparison: Enamel and Inlay Finishes

Enamel work offers a durable, glass-like surface resistant to scratches and fading, making it ideal for jewelry exposed to daily wear. Inlay finishes, crafted by embedding materials like stone or shell into metal, provide robust durability but may be prone to chipping under heavy impact. Both techniques enhance jewelry longevity, but enamel typically outperforms in maintaining color vibrancy, while inlay excels in resisting surface abrasion.

Market Trends: Consumer Preferences for Enamel or Inlay

Consumer preferences in jewelry making show a growing appreciation for enamel work due to its vibrant colors and intricate detailing, which appeal to modern fashion trends emphasizing bold and personalized accessories. Inlay work maintains steady demand, particularly among collectors who value traditional craftsmanship and the use of precious stones or materials embedded in metal. Market trends indicate a niche segmentation where enamel attracts younger buyers interested in contemporary designs, while inlay remains popular in luxury and heritage jewelry collections.

Cost Analysis: Enamel Work vs Inlay Work

Enamel work in jewelry typically demands higher material costs due to the use of fine powdered glass and specialized firing processes, whereas inlay work involves embedding stones or materials such as wood or metal, which can vary widely in expense depending on the chosen inlay materials. Labor intensity for enamel work often results in increased costs because of the precision and kiln firing stages required to achieve a smooth, durable finish. Inlay work may offer cost savings when using less expensive or readily available inlay materials, but bespoke designs with exotic or precious inlays can be equally or more costly than enamel techniques.

Skill Requirements and Learning Curves

Enamel work demands precise temperature control and steady hand coordination to fuse powdered glass onto metal surfaces, requiring extensive practice to master firing techniques and color blending. Inlay work involves embedding materials such as gemstones, wood, or metal into carved recesses, necessitating skills in detailed carving and material fitting that require patience and dexterity. Both crafts present unique learning curves, with enamel work emphasizing chemical and thermal processes, while inlay focuses on intricate handcrafting and material compatibility.

Customization Opportunities in Enamel and Inlay Jewelry

Enamel work offers vibrant color customization through layers of glass powder fused to metal, allowing artists to create intricate, personalized designs with a wide palette. Inlay work involves embedding materials such as stones, shells, or metals into the jewelry base, providing unique texture and pattern options tailored to individual preferences. Both techniques enable high levels of customization but differ in visual impact and material versatility, with enamel excelling in colorful detail and inlay emphasizing material contrast and dimension.

Which Technique to Choose for Your Jewelry Business?

Enamel work involves fusing powdered glass to metal surfaces at high temperatures, creating vibrant, durable, and corrosion-resistant finishes ideal for colorful designs and intricate patterns. Inlay work embeds materials such as gemstones, wood, or shell into metal recesses, offering dimensional texture and a luxurious, tactile appeal that highlights contrasting materials. Choosing between enamel and inlay techniques depends on your brand identity, target market preferences, and desired aesthetic, with enamel excelling in bold color expression and inlay emphasizing material contrast and craftsmanship detail.

Enamel work vs Inlay work Infographic

bizdif.com

bizdif.com