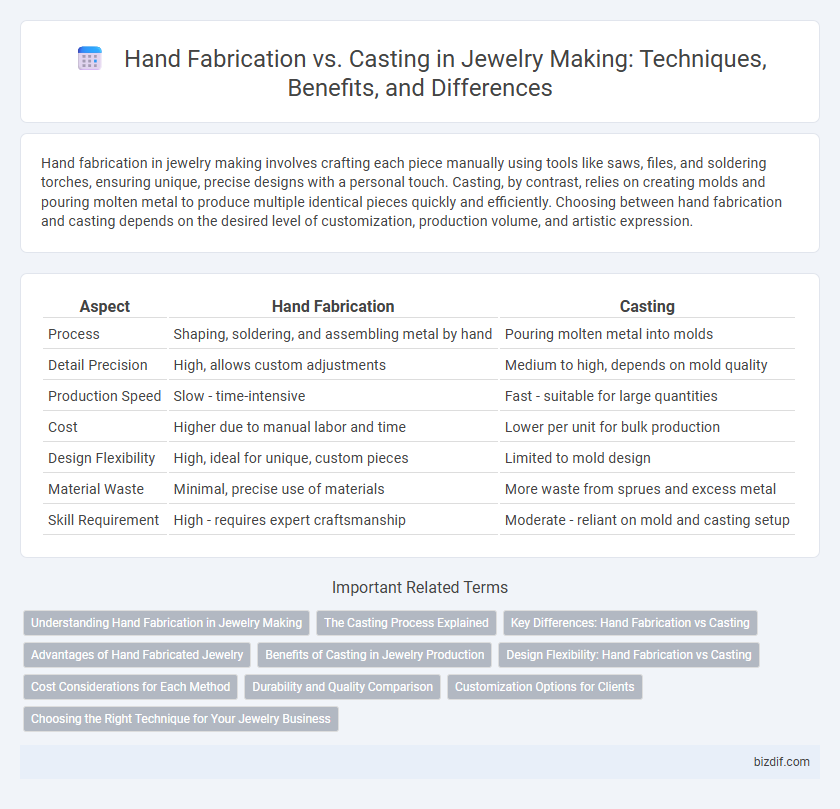

Hand fabrication in jewelry making involves crafting each piece manually using tools like saws, files, and soldering torches, ensuring unique, precise designs with a personal touch. Casting, by contrast, relies on creating molds and pouring molten metal to produce multiple identical pieces quickly and efficiently. Choosing between hand fabrication and casting depends on the desired level of customization, production volume, and artistic expression.

Table of Comparison

| Aspect | Hand Fabrication | Casting |

|---|---|---|

| Process | Shaping, soldering, and assembling metal by hand | Pouring molten metal into molds |

| Detail Precision | High, allows custom adjustments | Medium to high, depends on mold quality |

| Production Speed | Slow - time-intensive | Fast - suitable for large quantities |

| Cost | Higher due to manual labor and time | Lower per unit for bulk production |

| Design Flexibility | High, ideal for unique, custom pieces | Limited to mold design |

| Material Waste | Minimal, precise use of materials | More waste from sprues and excess metal |

| Skill Requirement | High - requires expert craftsmanship | Moderate - reliant on mold and casting setup |

Understanding Hand Fabrication in Jewelry Making

Hand fabrication in jewelry making involves the meticulous process of shaping and assembling metal components by hand using techniques such as sawing, soldering, hammering, and filing. This method allows for exceptional customization, intricate detailing, and the creation of unique, one-of-a-kind pieces that reflect the artisan's skill and creativity. Unlike casting, which relies on molds and mass production, hand fabrication offers greater flexibility for design adjustments and repairs, making it highly valued in bespoke jewelry crafting.

The Casting Process Explained

The casting process in jewelry making involves creating a detailed wax model that is encased in a heat-resistant mold material before melting out the wax to form a cavity. Molten metal is then poured into this cavity, capturing intricate designs and enabling mass production of consistent pieces. This method contrasts with hand fabrication, which relies on manually shaping and assembling metal components for more custom and unique results.

Key Differences: Hand Fabrication vs Casting

Hand fabrication in jewelry making involves manually cutting, shaping, and soldering metal pieces to create unique, custom designs with precise control over detail and texture. Casting uses molds and molten metal to reproduce designs efficiently, ideal for producing multiple identical pieces with consistent quality. Key differences include the level of customization, production speed, and the typical application, where hand fabrication suits bespoke creations and casting excels in mass production.

Advantages of Hand Fabricated Jewelry

Hand fabricated jewelry offers unparalleled customization, allowing artisans to create intricate, one-of-a-kind designs tailored to specific customer preferences. It provides superior structural integrity since each piece is meticulously crafted and assembled by skilled hands, resulting in durable and long-lasting jewelry. This method also reduces material waste, making it an eco-friendly option compared to casting processes.

Benefits of Casting in Jewelry Production

Casting in jewelry production offers precise replication of intricate designs, enabling consistent quality and high detail in each piece. It allows for efficient mass production, reducing labor costs and turnaround time compared to hand fabrication. The process supports versatile material use, including gold, silver, and platinum, making it ideal for producing complex, fine jewelry at scale.

Design Flexibility: Hand Fabrication vs Casting

Hand fabrication offers unmatched design flexibility, allowing jewelers to create unique, intricate pieces with precise control over every detail through techniques like soldering and shaping metal sheets and wires. Casting, while efficient for producing complex shapes and repeating patterns via molds, limits customization once the mold is created, making it less adaptable for one-of-a-kind designs. Artisans favor hand fabrication for bespoke jewelry requiring intricate detailing and individualized adjustments that casting processes cannot easily accommodate.

Cost Considerations for Each Method

Hand fabrication often involves higher labor costs due to the skilled craftsmanship and time-intensive processes required for shaping metal by hand, making it more expensive for intricate or custom pieces. Casting typically reduces overall production costs by enabling bulk creation of identical components through molds, which lowers material waste and speeds up manufacturing. Evaluating the scale and complexity of the jewelry design helps determine whether the investment in hand fabrication or the cost-efficiency of casting is the more economical choice.

Durability and Quality Comparison

Hand fabrication in jewelry making offers superior durability and quality due to meticulous craftsmanship and the use of solid metal sheets or wires, resulting in stronger, more resilient pieces. Casting often involves molten metal poured into molds, which can sometimes introduce porosity or imperfections that compromise structural integrity over time. Quality control in hand fabrication is typically higher as each component is individually shaped and joined, ensuring a refined finish and longer-lasting jewelry.

Customization Options for Clients

Hand fabrication offers unparalleled customization options, allowing jewelers to create unique, intricate designs tailored precisely to clients' specifications and preferences. Casting provides efficient reproduction of detailed models but typically limits the ability to make individual alterations on each piece. Clients seeking one-of-a-kind, highly personalized jewelry often prefer the flexibility and artisanal craftsmanship found in hand fabrication over the standardized nature of casting.

Choosing the Right Technique for Your Jewelry Business

Hand fabrication offers unparalleled control and customization, allowing jewelers to create unique, high-quality pieces with intricate details, ideal for bespoke designs and limited production runs. Casting suits mass production by efficiently replicating complex shapes with consistent precision, lowering costs per unit and speeding up manufacturing times. Selecting the right technique depends on your business goals, target market, production volume, and desired product uniqueness to maximize profitability and brand identity.

Hand fabrication vs Casting Infographic

bizdif.com

bizdif.com