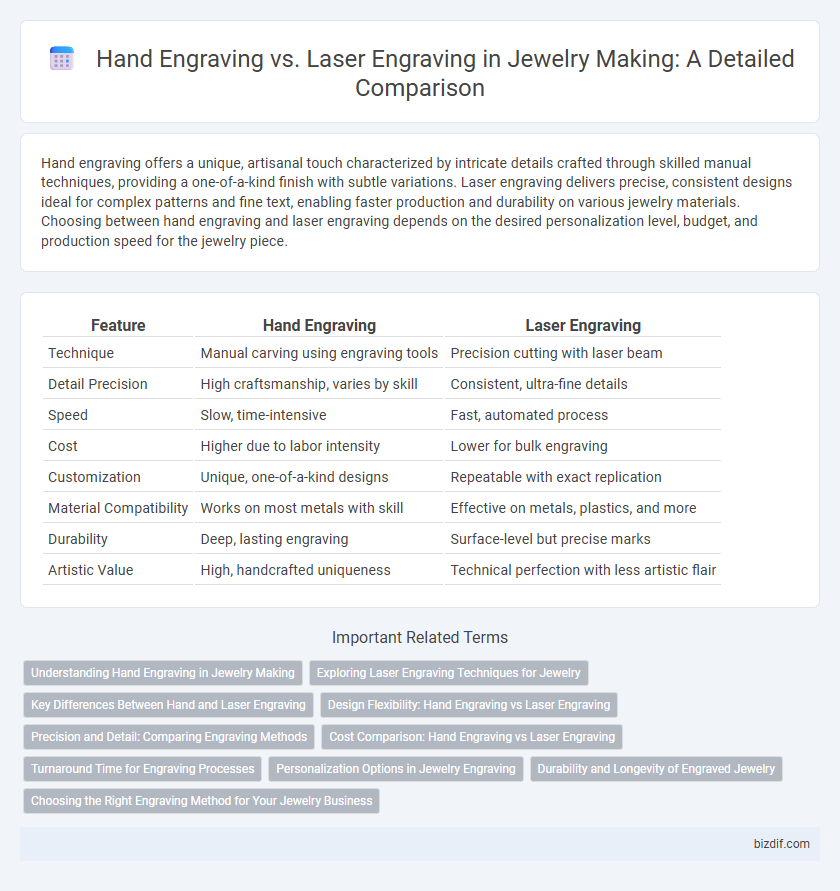

Hand engraving offers a unique, artisanal touch characterized by intricate details crafted through skilled manual techniques, providing a one-of-a-kind finish with subtle variations. Laser engraving delivers precise, consistent designs ideal for complex patterns and fine text, enabling faster production and durability on various jewelry materials. Choosing between hand engraving and laser engraving depends on the desired personalization level, budget, and production speed for the jewelry piece.

Table of Comparison

| Feature | Hand Engraving | Laser Engraving |

|---|---|---|

| Technique | Manual carving using engraving tools | Precision cutting with laser beam |

| Detail Precision | High craftsmanship, varies by skill | Consistent, ultra-fine details |

| Speed | Slow, time-intensive | Fast, automated process |

| Cost | Higher due to labor intensity | Lower for bulk engraving |

| Customization | Unique, one-of-a-kind designs | Repeatable with exact replication |

| Material Compatibility | Works on most metals with skill | Effective on metals, plastics, and more |

| Durability | Deep, lasting engraving | Surface-level but precise marks |

| Artistic Value | High, handcrafted uniqueness | Technical perfection with less artistic flair |

Understanding Hand Engraving in Jewelry Making

Hand engraving in jewelry making involves using traditional tools like gravers to carve intricate designs directly onto metal surfaces, creating unique, personalized pieces with a high level of craftsmanship. This technique requires skilled artisanship, allowing for depth, texture, and subtle variations that laser engraving often cannot replicate. Hand engraving adds a timeless, artistic quality to jewelry, enhancing its value and individuality through meticulous, manual detail work.

Exploring Laser Engraving Techniques for Jewelry

Laser engraving techniques for jewelry offer unparalleled precision and the ability to create intricate, detailed designs on various metals, including gold, silver, and platinum. This method uses focused laser beams to etch patterns without physical contact, reducing the risk of damage and allowing for high customization with speed and consistency. Compared to hand engraving, laser engraving enhances efficiency while maintaining fine artistic quality, making it ideal for personalized and complex jewelry pieces.

Key Differences Between Hand and Laser Engraving

Hand engraving offers intricate, personalized designs crafted by skilled artisans using traditional tools, resulting in unique, textured patterns often preferred for custom jewelry pieces. Laser engraving employs precise, computer-controlled beams to create consistent, detailed markings quickly on various materials, ideal for mass production and intricate fonts or logos. The key difference lies in the craftsmanship and tactile depth of hand engraving versus the speed, repeatability, and fine detail achievable with laser engraving technology.

Design Flexibility: Hand Engraving vs Laser Engraving

Hand engraving offers unparalleled design flexibility, enabling intricate, customized patterns crafted with precise manual skill that captures subtle nuances and depth. Laser engraving provides exceptional precision and repeatability for complex, detailed designs but may lack the organic, textured qualities achieved by handwork. Choosing between the two methods depends on whether the design prioritizes artisanal uniqueness or highly detailed, consistent replication.

Precision and Detail: Comparing Engraving Methods

Hand engraving offers unmatched precision and intricate detail due to the artisan's skill and control over the tool, allowing for unique, personalized designs with subtle depth variations. Laser engraving delivers exceptional accuracy and consistency, capable of producing highly detailed and complex patterns at microscopic levels, ideal for intricate logos or text replication. While hand engraving excels in creating bespoke, textured finishes, laser engraving provides precision in mass production with minimal human error.

Cost Comparison: Hand Engraving vs Laser Engraving

Hand engraving typically demands higher labor costs due to the skilled craftsmanship and time-intensive process involved, making it more expensive for intricate, custom designs. Laser engraving offers a cost-effective alternative with faster turnaround times and minimal manual labor, especially suitable for bulk production or repetitive patterns. When comparing costs, laser engraving is generally more affordable for large orders, while hand engraving commands premium pricing for unique, artisanal pieces.

Turnaround Time for Engraving Processes

Hand engraving typically requires several hours to days depending on the complexity and size of the design, offering a highly detailed and personalized finish. Laser engraving significantly reduces turnaround time, often completing intricate patterns within minutes due to its precision and automation. Choosing between hand and laser engraving balances the need for artisanal craftsmanship against the demand for rapid production in jewelry making.

Personalization Options in Jewelry Engraving

Hand engraving offers intricate, unique designs with a personalized touch, allowing artisans to create customizable patterns, initials, or symbols that reflect individual craftsmanship. Laser engraving provides precise, consistent personalization with complex details, enabling fine text or images on delicate jewelry surfaces. Both techniques enhance customization but differ in style and depth, catering to various preferences in jewelry engraving.

Durability and Longevity of Engraved Jewelry

Hand engraving creates deep, precise cuts that maintain their clarity and texture over time, offering exceptional durability and a timeless, artisanal quality. Laser engraving, while capable of producing intricate and consistent designs quickly, often results in shallower markings that may wear down faster with frequent use. For long-lasting engraved jewelry, hand engraving is generally preferred due to its superior resistance to fading and abrasion.

Choosing the Right Engraving Method for Your Jewelry Business

Hand engraving offers a unique, artisanal touch with intricate details that appeal to clients seeking personalized craftsmanship, while laser engraving ensures precision, speed, and consistency ideal for mass production and complex designs. Selecting the right engraving method depends on factors such as production volume, design complexity, budget, and customer preferences within your jewelry business. Combining both techniques can balance exclusivity with efficiency, maximizing business flexibility and client satisfaction.

Hand engraving vs Laser engraving Infographic

bizdif.com

bizdif.com