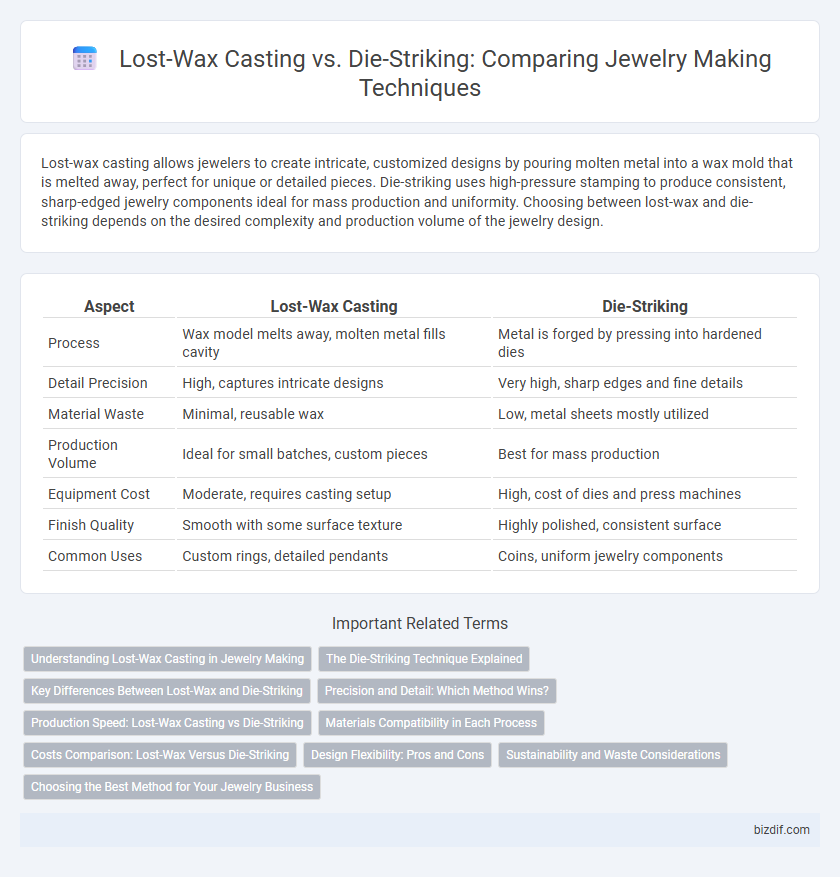

Lost-wax casting allows jewelers to create intricate, customized designs by pouring molten metal into a wax mold that is melted away, perfect for unique or detailed pieces. Die-striking uses high-pressure stamping to produce consistent, sharp-edged jewelry components ideal for mass production and uniformity. Choosing between lost-wax and die-striking depends on the desired complexity and production volume of the jewelry design.

Table of Comparison

| Aspect | Lost-Wax Casting | Die-Striking |

|---|---|---|

| Process | Wax model melts away, molten metal fills cavity | Metal is forged by pressing into hardened dies |

| Detail Precision | High, captures intricate designs | Very high, sharp edges and fine details |

| Material Waste | Minimal, reusable wax | Low, metal sheets mostly utilized |

| Production Volume | Ideal for small batches, custom pieces | Best for mass production |

| Equipment Cost | Moderate, requires casting setup | High, cost of dies and press machines |

| Finish Quality | Smooth with some surface texture | Highly polished, consistent surface |

| Common Uses | Custom rings, detailed pendants | Coins, uniform jewelry components |

Understanding Lost-Wax Casting in Jewelry Making

Lost-wax casting in jewelry making involves creating a detailed wax model that is encased in a refractory mold; upon heating, the wax melts away, leaving a precise cavity for molten metal to fill. This technique allows for intricate designs and complex shapes that die-striking cannot easily achieve due to its reliance on stamping metal sheets. The ability to capture fine details and organic textures makes lost-wax casting ideal for custom and artistic jewelry pieces.

The Die-Striking Technique Explained

Die-striking is a jewelry-making technique that involves stamping metal sheets using high-pressure dies to create precise, detailed designs often used for coins, medallions, and badges. This method offers superior consistency and durability compared to lost-wax casting, especially for mass production of flat or slightly curved pieces. The high-pressure striking process increases metal density, resulting in a harder, more wear-resistant surface ideal for intricate, repeating patterns.

Key Differences Between Lost-Wax and Die-Striking

Lost-wax casting involves creating a detailed wax model that is melted away to form a mold for molten metal, enabling intricate and highly customizable designs with fine details and organic shapes. Die-striking uses hardened steel dies to stamp designs onto metal sheets, producing consistent and precise pieces ideal for mass production but limited in complexity and depth. The key differences center on customization and detail with lost-wax versus efficiency and uniformity with die-striking, affecting cost, production speed, and design complexity in jewelry making.

Precision and Detail: Which Method Wins?

Lost-wax casting excels in capturing intricate details and organic shapes due to its ability to reproduce fine textures from wax models, making it ideal for complex, custom jewelry designs. Die-striking offers superior precision and consistency for mass-produced pieces, creating sharp lines and uniform thickness through high-pressure metal stamping. For ultimate detail in unique, artisanal jewelry, lost-wax casting wins, while die-striking leads in precision for large-scale production.

Production Speed: Lost-Wax Casting vs Die-Striking

Lost-wax casting offers slower production speed due to its intricate mold-making and wax model processes, making it ideal for detailed and custom pieces. Die-striking enables rapid production by stamping metal sheets with precision dies, suitable for high-volume jewelry with consistent designs. Manufacturers prioritize die-striking when fast turnaround and uniformity are critical, while lost-wax casting remains preferred for artisanal and complex jewelry requiring fine detail.

Materials Compatibility in Each Process

Lost-wax casting accommodates a wide range of metals including gold, silver, platinum, and bronze, providing superior detail and versatility for complex designs. Die-striking is best suited for softer metals such as silver, gold, and copper, but is limited in working with high-melting-point alloys. Each process requires careful material selection to optimize durability, finish quality, and design intricacy.

Costs Comparison: Lost-Wax Versus Die-Striking

Lost-wax casting typically incurs higher initial costs due to the detailed wax model creation and labor-intensive process, making it ideal for intricate, custom designs. Die-striking requires significant upfront investment in metal dies but offers lower per-unit costs for mass production, enhancing cost efficiency at large scales. Choosing between lost-wax and die-striking depends on balancing the complexity of design against production volume and budget constraints.

Design Flexibility: Pros and Cons

Lost-wax casting offers exceptional design flexibility, enabling intricate, organic shapes and fine details that are often impossible to achieve with die-striking. However, die-striking excels in producing uniform, high-volume pieces with sharp, consistent patterns but is limited to simpler, flatter designs due to the rigidity of metal dies. Choosing between these methods depends on the desired complexity and production scale of the jewelry design.

Sustainability and Waste Considerations

Lost-wax casting in jewelry making generates minimal waste as it allows precise molten metal usage, with the investment mold being reusable for multiple cycles, enhancing sustainability. Die-striking produces less material waste per piece due to efficient metal blanks and can recycle scrap metal effectively, supporting circular resource use. Both techniques emphasize reducing environmental impact, but lost-wax casting excels in detail with lower raw material consumption, aligning with sustainable craftsmanship goals.

Choosing the Best Method for Your Jewelry Business

Lost-wax casting offers unparalleled design flexibility and intricate detail, making it ideal for custom or small-batch jewelry pieces. Die striking excels in high-volume production due to its speed and consistent precision, suitable for classic, repetitive designs. Selecting the best method depends on factors like production scale, design complexity, and budget constraints specific to your jewelry business.

Lost-wax vs Die-striking Infographic

bizdif.com

bizdif.com