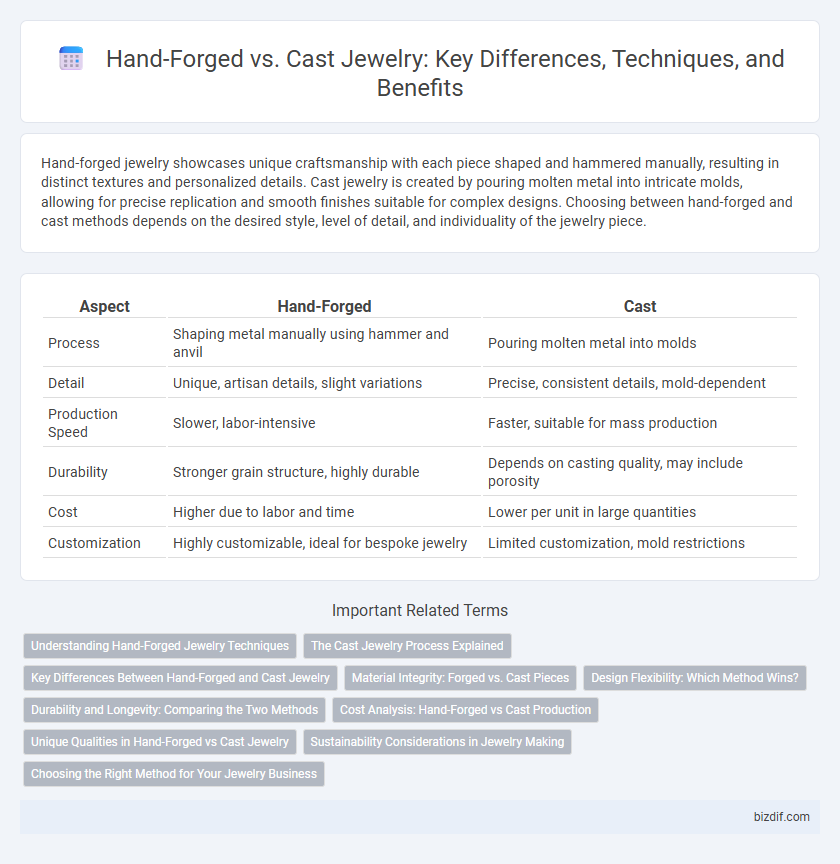

Hand-forged jewelry showcases unique craftsmanship with each piece shaped and hammered manually, resulting in distinct textures and personalized details. Cast jewelry is created by pouring molten metal into intricate molds, allowing for precise replication and smooth finishes suitable for complex designs. Choosing between hand-forged and cast methods depends on the desired style, level of detail, and individuality of the jewelry piece.

Table of Comparison

| Aspect | Hand-Forged | Cast |

|---|---|---|

| Process | Shaping metal manually using hammer and anvil | Pouring molten metal into molds |

| Detail | Unique, artisan details, slight variations | Precise, consistent details, mold-dependent |

| Production Speed | Slower, labor-intensive | Faster, suitable for mass production |

| Durability | Stronger grain structure, highly durable | Depends on casting quality, may include porosity |

| Cost | Higher due to labor and time | Lower per unit in large quantities |

| Customization | Highly customizable, ideal for bespoke jewelry | Limited customization, mold restrictions |

Understanding Hand-Forged Jewelry Techniques

Hand-forged jewelry involves shaping metal by hammering and bending, allowing artisans to create unique textures and intricate details that highlight craftsmanship. This technique enhances the durability and personalization of pieces, often resulting in one-of-a-kind designs with subtle variations. Understanding hand-forged processes is essential for appreciating the artisanal value and distinct character compared to cast jewelry.

The Cast Jewelry Process Explained

The cast jewelry process involves creating a wax model that is encased in a heat-resistant material to form a mold, which is then heated to melt away the wax, leaving a cavity for molten metal to be poured in. This process allows for intricate and highly detailed designs that are difficult to achieve with hand-forging, making it ideal for complex pieces and mass production. Casting provides precise replication of jewelry components with consistent quality and smooth finishes, essential for intricate gemstones settings and delicate metalwork.

Key Differences Between Hand-Forged and Cast Jewelry

Hand-forged jewelry is crafted by shaping metal manually using hammers and anvils, resulting in unique, customizable pieces with distinct textures and enhanced durability. Cast jewelry involves pouring molten metal into molds, allowing for intricate designs and mass production but often yielding less strength and individuality. The key differences lie in production methods, detail precision, material properties, and the artisanal value of each piece.

Material Integrity: Forged vs. Cast Pieces

Hand-forged jewelry maintains superior material integrity by aligning metal grains through hammering, resulting in enhanced strength and durability compared to cast pieces. Cast jewelry, formed by pouring molten metal into molds, may exhibit porosity and internal imperfections that compromise structural consistency. The forging process produces denser, more resilient components ideal for high-quality, long-lasting jewelry designs.

Design Flexibility: Which Method Wins?

Hand-forged jewelry offers exceptional design flexibility, allowing artisans to create intricate, one-of-a-kind pieces through direct manipulation of metal. Cast jewelry provides consistency and the ability to produce complex shapes in large quantities by pouring molten metal into detailed molds. For unique, customizable designs, hand-forging is preferred, while casting excels in replicating precise patterns with efficiency.

Durability and Longevity: Comparing the Two Methods

Hand-forged jewelry typically exhibits superior durability due to the dense metal structure formed during the hammering process, resulting in pieces that withstand wear and tear over time. Cast jewelry, while allowing for intricate and consistent designs, may have microscopic air pockets that can compromise long-term strength and increase susceptibility to damage. Choosing hand-forged methods often ensures longevity and resilience in fine jewelry, making it ideal for heirlooms and items subjected to frequent use.

Cost Analysis: Hand-Forged vs Cast Production

Hand-forged jewelry typically incurs higher labor costs due to the intensive manual work and time required, making it more expensive per piece compared to cast production. Cast jewelry benefits from economies of scale, as molds enable mass production with lower material waste and quicker turnaround, reducing overall costs. However, hand-forged pieces often command higher prices owing to their unique craftsmanship and limited quantities.

Unique Qualities in Hand-Forged vs Cast Jewelry

Hand-forged jewelry offers unparalleled uniqueness through its artisanal craftsmanship, with each piece shaped by skilled hands resulting in subtle variations and organic textures that cannot be replicated. Cast jewelry, produced by pouring molten metal into molds, provides consistent shapes and intricate designs but lacks the individual character inherent in hand-forging. The tactile quality and durable structural integrity of hand-forged pieces appeal to collectors valuing exclusivity and timeless artistry over mass-produced perfection.

Sustainability Considerations in Jewelry Making

Hand-forged jewelry emphasizes sustainability through reduced energy consumption and minimal waste, as artisans shape metal manually without relying on energy-intensive molds or machinery. Cast jewelry often involves melting metals at high temperatures, leading to higher carbon emissions and the potential use of harmful chemicals in mold creation and metal finishing. Choosing hand-forged techniques supports eco-friendly practices by promoting recyclability and resource efficiency in the jewelry-making process.

Choosing the Right Method for Your Jewelry Business

Hand-forged jewelry offers unparalleled customization and durability due to the artisan's direct manipulation of metals, ideal for unique, high-quality pieces that command premium pricing. Cast jewelry, created through molds and molten metal, enables mass production with consistent design replication, making it suitable for businesses targeting volume and efficiency. Selecting the right method depends on your brand's focus--hand-forging emphasizes craftsmanship and exclusivity, while casting prioritizes scalability and cost-effectiveness.

Hand-forged vs Cast Infographic

bizdif.com

bizdif.com