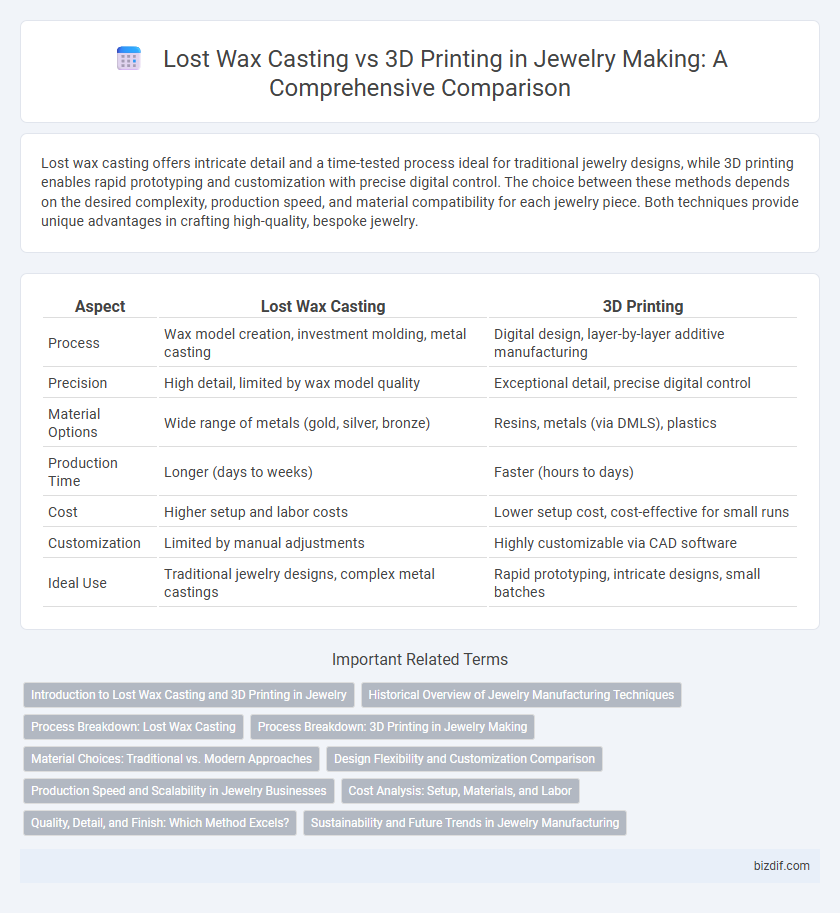

Lost wax casting offers intricate detail and a time-tested process ideal for traditional jewelry designs, while 3D printing enables rapid prototyping and customization with precise digital control. The choice between these methods depends on the desired complexity, production speed, and material compatibility for each jewelry piece. Both techniques provide unique advantages in crafting high-quality, bespoke jewelry.

Table of Comparison

| Aspect | Lost Wax Casting | 3D Printing |

|---|---|---|

| Process | Wax model creation, investment molding, metal casting | Digital design, layer-by-layer additive manufacturing |

| Precision | High detail, limited by wax model quality | Exceptional detail, precise digital control |

| Material Options | Wide range of metals (gold, silver, bronze) | Resins, metals (via DMLS), plastics |

| Production Time | Longer (days to weeks) | Faster (hours to days) |

| Cost | Higher setup and labor costs | Lower setup cost, cost-effective for small runs |

| Customization | Limited by manual adjustments | Highly customizable via CAD software |

| Ideal Use | Traditional jewelry designs, complex metal castings | Rapid prototyping, intricate designs, small batches |

Introduction to Lost Wax Casting and 3D Printing in Jewelry

Lost wax casting, an ancient technique, involves creating a detailed wax model that is encased in a mold to be melted away, leaving a cavity for molten metal to form intricate jewelry designs. 3D printing revolutionizes this process by enabling precise, computer-generated wax or resin models directly from digital files, reducing production time and enhancing customization. Both methods blend craftsmanship and technology to produce high-quality, detailed jewelry with unique textures and complexities.

Historical Overview of Jewelry Manufacturing Techniques

Lost wax casting, dating back over 5,000 years, remains a cornerstone in jewelry manufacturing due to its precision in creating intricate metal designs from wax models. In contrast, 3D printing represents a revolutionary advancement, enabling rapid prototyping and complex geometries unattainable by traditional methods. The historical evolution from artisanal lost wax casting to digital 3D printing marks a significant shift in craftsmanship, material efficiency, and design innovation within the jewelry industry.

Process Breakdown: Lost Wax Casting

Lost wax casting involves creating a detailed wax model of the jewelry piece, which is then encased in a heat-resistant mold material. Once the mold hardens, the wax is melted and drained away, leaving a precise cavity that captures every detail of the design. Molten metal is poured into this cavity to form the final piece, ensuring high fidelity and intricate craftsmanship.

Process Breakdown: 3D Printing in Jewelry Making

3D printing in jewelry making begins with creating a detailed digital design using CAD software, which allows precise customization and complex geometries. The digital file is then sent to a 3D printer that builds the model layer by layer, often using resin or wax-like materials suitable for casting. This process reduces production time and material waste compared to traditional lost wax casting, enabling rapid prototyping and intricate designs with high accuracy.

Material Choices: Traditional vs. Modern Approaches

Lost wax casting typically uses wax for model creation that is later replaced by molten metals such as gold, silver, and bronze, emphasizing traditional materials with proven durability and aesthetic quality. In contrast, 3D printing allows for a wider range of materials including resin, plastic, and metal powders, offering innovative possibilities and precise designs. Modern 3D printing techniques enable jewelers to experiment with material composites and intricate details that are difficult to achieve through traditional lost wax methods.

Design Flexibility and Customization Comparison

Lost wax casting offers intricate detailing and organic shapes due to its traditional hand-carved wax models, providing high customization for bespoke jewelry pieces. In contrast, 3D printing enables precise, repeatable designs with complex geometries that are difficult to achieve manually, enhancing design flexibility and rapid prototyping. Both methods allow tailored creations, but 3D printing excels in iterative adjustments and intricate patterns, while lost wax casting maintains an artisanal, handcrafted aesthetic.

Production Speed and Scalability in Jewelry Businesses

Lost wax casting offers high detail and finish quality but typically involves longer production times due to mold preparation and manual steps, limiting scalability for large orders. In contrast, 3D printing significantly accelerates prototype development and small-batch production, enabling rapid iteration and faster turnaround for custom jewelry pieces. Jewelry businesses benefit from integrating 3D printing to enhance production speed and scale operations efficiently, especially when managing diverse designs and high demand.

Cost Analysis: Setup, Materials, and Labor

Lost wax casting involves higher upfront costs due to mold creation and wax model production, whereas 3D printing requires investment in printers and digital design software but reduces manual labor expenses. Material costs for lost wax casting include wax and metal alloys, while 3D printing uses resin or metal powders, often resulting in lower waste and material efficiency. Labor intensity is greater in lost wax casting because of multiple hands-on steps, whereas 3D printing streamlines production, cutting labor time and costs significantly.

Quality, Detail, and Finish: Which Method Excels?

Lost wax casting offers unparalleled detail and a superior finish, producing intricate jewelry with a rich, traditional texture prized by artisans. 3D printing excels in precision and consistency, enabling highly detailed designs with minimal imperfections but may require post-processing to match the smoothness of cast pieces. For quality and finish, lost wax casting remains the gold standard, while 3D printing provides innovative accuracy and faster prototyping options in jewelry making.

Sustainability and Future Trends in Jewelry Manufacturing

Lost wax casting remains a traditional method in jewelry making, valued for its precision but involves high energy consumption and wax waste. 3D printing offers a sustainable alternative by significantly reducing material waste and enabling precise, custom designs with minimal environmental impact. Future trends emphasize integrating 3D printing with eco-friendly materials and digital workflows to enhance sustainability throughout the jewelry manufacturing process.

Lost wax casting vs 3D printing Infographic

bizdif.com

bizdif.com