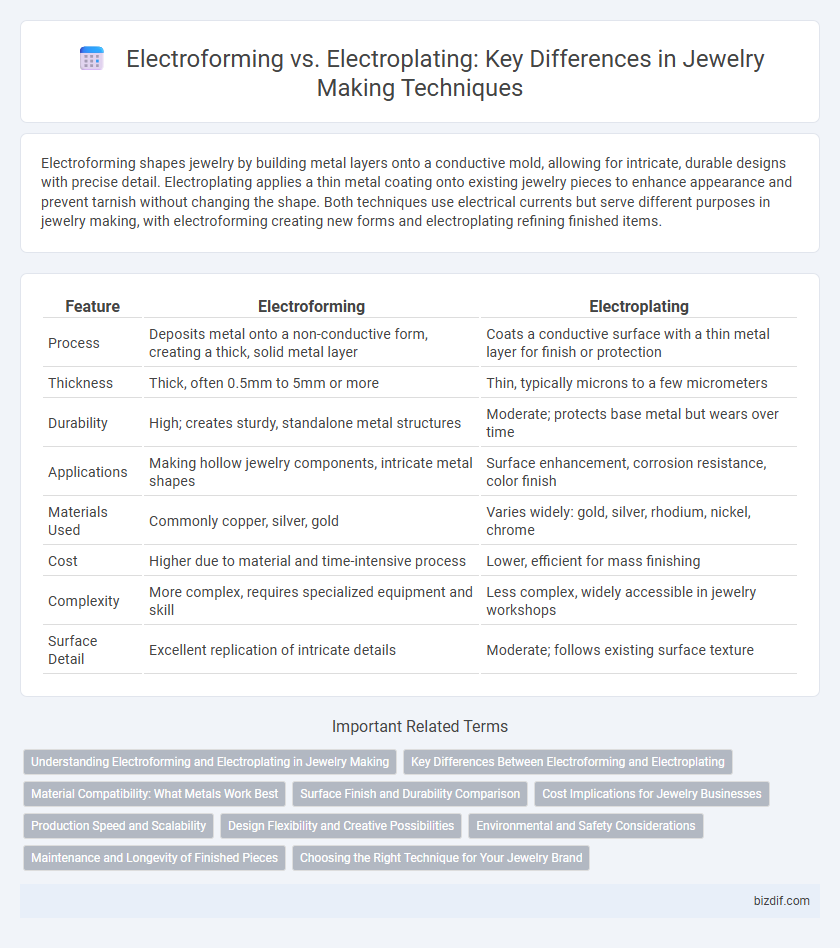

Electroforming shapes jewelry by building metal layers onto a conductive mold, allowing for intricate, durable designs with precise detail. Electroplating applies a thin metal coating onto existing jewelry pieces to enhance appearance and prevent tarnish without changing the shape. Both techniques use electrical currents but serve different purposes in jewelry making, with electroforming creating new forms and electroplating refining finished items.

Table of Comparison

| Feature | Electroforming | Electroplating |

|---|---|---|

| Process | Deposits metal onto a non-conductive form, creating a thick, solid metal layer | Coats a conductive surface with a thin metal layer for finish or protection |

| Thickness | Thick, often 0.5mm to 5mm or more | Thin, typically microns to a few micrometers |

| Durability | High; creates sturdy, standalone metal structures | Moderate; protects base metal but wears over time |

| Applications | Making hollow jewelry components, intricate metal shapes | Surface enhancement, corrosion resistance, color finish |

| Materials Used | Commonly copper, silver, gold | Varies widely: gold, silver, rhodium, nickel, chrome |

| Cost | Higher due to material and time-intensive process | Lower, efficient for mass finishing |

| Complexity | More complex, requires specialized equipment and skill | Less complex, widely accessible in jewelry workshops |

| Surface Detail | Excellent replication of intricate details | Moderate; follows existing surface texture |

Understanding Electroforming and Electroplating in Jewelry Making

Electroforming in jewelry making creates thick, durable metal layers by depositing metal onto a conductive mold, enabling the creation of lightweight, hollow pieces with intricate details. Electroplating involves applying a thin metal coating over a base metal to enhance appearance, corrosion resistance, and surface smoothness without altering the piece's weight or structure. Both techniques use electrical current and metal solutions but serve distinct purposes in jewelry fabrication and finishing.

Key Differences Between Electroforming and Electroplating

Electroforming builds up a thick layer of metal through prolonged electrodeposition, allowing for the creation of hollow, lightweight, and detailed metal pieces, while electroplating deposits a thin metal layer onto a solid substrate primarily for surface enhancement and corrosion resistance. Electroforming requires a conductive model and often uses metals like copper or nickel, whereas electroplating commonly employs metals such as gold, silver, or chromium to improve appearance and durability. The key difference lies in electroforming's ability to create standalone metal objects versus electroplating's role as a surface finish process.

Material Compatibility: What Metals Work Best

Electroforming is highly compatible with conductive metals like copper, brass, and silver, allowing for thick, durable layers ideal for intricate jewelry designs. Electroplating works best on a wider variety of base metals such as nickel, steel, and zinc, providing a thin, decorative coating that enhances appearance without altering the core material. Both processes require thorough surface preparation to ensure strong adhesion and optimal finish quality.

Surface Finish and Durability Comparison

Electroforming produces thicker metal deposits, resulting in a more durable and robust surface finish ideal for intricate jewelry designs that require long-lasting detail. Electroplating coats jewelry with a thinner, more delicate metal layer, which enhances appearance but wears off faster under regular use. Surface finish from electroforming tends to have more texture and depth, while electroplating offers a smoother, glossier appearance but requires more maintenance to preserve durability.

Cost Implications for Jewelry Businesses

Electroforming requires higher initial investment due to specialized equipment and thicker metal deposits, increasing production costs but offering durability and design flexibility. Electroplating presents lower upfront expenses and faster processing times, making it more cost-effective for high-volume, lightweight pieces. Jewelry businesses must balance these cost implications against product quality and target market preferences to maximize profitability.

Production Speed and Scalability

Electroforming offers slower production speeds compared to electroplating due to its layer-by-layer metal deposition, which can take several hours to build substantial thickness. Electroplating accelerates scalability in jewelry manufacturing by quickly depositing thin, uniform metal layers, allowing for high-volume production with consistent finish quality. Choosing electroplating enhances production efficiency and scalability for mass-market jewelry, while electroforming suits custom pieces requiring thicker, structural metal layers.

Design Flexibility and Creative Possibilities

Electroforming offers greater design flexibility by allowing artisans to create intricate, lightweight, and hollow metal structures directly from non-metallic models, enabling complex shapes not achievable with traditional methods. Electroplating primarily enhances surface aesthetics and durability by depositing a thin metal layer over existing pieces, limiting creative possibilities to surface treatments rather than structural innovation. Jewelry makers leverage electroforming for unique, sculptural designs, while electroplating is favored for color variation and finishing touches.

Environmental and Safety Considerations

Electroforming uses thicker metal layers, resulting in more waste-heavy metal solutions requiring careful disposal to avoid environmental contamination, while electroplating typically produces thinner coatings with less hazardous waste. Both techniques involve toxic chemicals like cyanide and heavy metals, necessitating proper ventilation, protective gear, and strict handling protocols to ensure worker safety. Choosing eco-friendly metal baths and implementing recycling practices significantly reduce environmental impact in jewelry production.

Maintenance and Longevity of Finished Pieces

Electroforming creates thicker metal layers, resulting in more durable jewelry with enhanced resistance to wear and corrosion, reducing the need for frequent maintenance. Electroplated pieces have thinner metallic coatings that may wear off over time, requiring regular re-plating to maintain their appearance. Proper cleaning with gentle, non-abrasive materials extends the longevity of both electroformed and electroplated jewelry, but electroformed pieces generally offer superior long-term durability.

Choosing the Right Technique for Your Jewelry Brand

Electroforming provides jewelry brands with the ability to create lightweight, hollow metal pieces featuring intricate designs by depositing thick layers of metal onto conductive molds, ideal for bold and unique statements. Electroplating suits brands aiming to enhance existing jewelry surfaces, offering a thin metal coating that improves durability and appearance without altering the original shape, perfect for delicate or detailed items. Selecting between electroforming and electroplating depends on the desired design complexity, metal thickness, and production goals to align with a brand's aesthetic and functional requirements.

Electroforming vs Electroplating Infographic

bizdif.com

bizdif.com