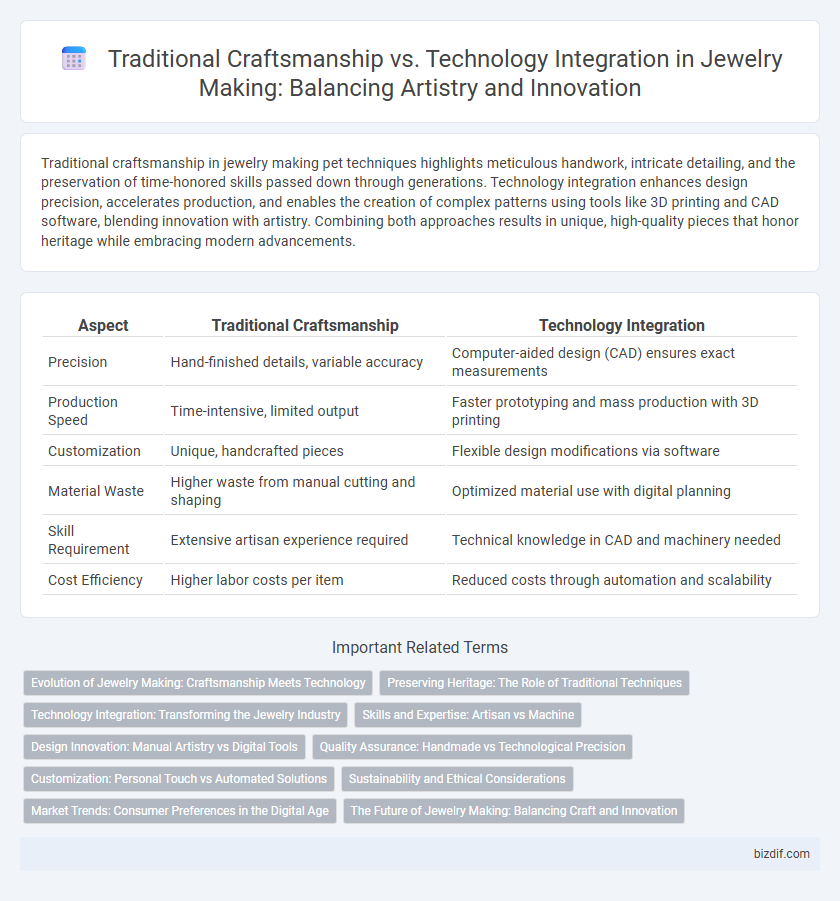

Traditional craftsmanship in jewelry making pet techniques highlights meticulous handwork, intricate detailing, and the preservation of time-honored skills passed down through generations. Technology integration enhances design precision, accelerates production, and enables the creation of complex patterns using tools like 3D printing and CAD software, blending innovation with artistry. Combining both approaches results in unique, high-quality pieces that honor heritage while embracing modern advancements.

Table of Comparison

| Aspect | Traditional Craftsmanship | Technology Integration |

|---|---|---|

| Precision | Hand-finished details, variable accuracy | Computer-aided design (CAD) ensures exact measurements |

| Production Speed | Time-intensive, limited output | Faster prototyping and mass production with 3D printing |

| Customization | Unique, handcrafted pieces | Flexible design modifications via software |

| Material Waste | Higher waste from manual cutting and shaping | Optimized material use with digital planning |

| Skill Requirement | Extensive artisan experience required | Technical knowledge in CAD and machinery needed |

| Cost Efficiency | Higher labor costs per item | Reduced costs through automation and scalability |

Evolution of Jewelry Making: Craftsmanship Meets Technology

Traditional craftsmanship in jewelry making preserves artisanal techniques such as hand engraving, stone setting, and filigree work, ensuring each piece reflects cultural heritage and intricate detail. The integration of technology introduces 3D printing, computer-aided design (CAD), and laser cutting, allowing for greater precision, customization, and faster production times. This evolution harmonizes the art of manual skill with digital innovation, expanding creative possibilities while maintaining high-quality craftsmanship standards.

Preserving Heritage: The Role of Traditional Techniques

Traditional craftsmanship in jewelry making preserves heritage by maintaining time-honored techniques such as hand engraving, filigree, and stone setting, which embody cultural histories and artisan skills passed down through generations. These meticulous methods ensure unique, high-quality pieces that reflect authenticity and artistic value, contrasting with mass-produced items. Integrating traditional techniques with modern technology enhances precision while safeguarding the cultural significance and individuality of each handcrafted creation.

Technology Integration: Transforming the Jewelry Industry

Technology integration in jewelry making is revolutionizing design precision and production efficiency through tools like 3D printing and CAD software. Advanced techniques enable intricate customization and faster prototyping, reducing material waste and labor costs. The fusion of digital innovation with artisanal skill enhances creativity, quality control, and market responsiveness in the jewelry industry.

Skills and Expertise: Artisan vs Machine

Traditional craftsmanship in jewelry making relies heavily on the skilled hands and deep expertise of artisans who create intricate designs through years of practice and a profound understanding of materials. Technology integration introduces precision machines and computer-aided design (CAD) tools that enhance accuracy, consistency, and production speed while reducing human error. The synergy of artisan skills and advanced technology leads to innovative pieces that blend artistic creativity with technical perfection.

Design Innovation: Manual Artistry vs Digital Tools

Traditional craftsmanship in jewelry making emphasizes intricate manual artistry, showcasing skilled hand-engraving, stone setting, and metalworking techniques passed down through generations. Digital tools such as CAD software and 3D printing enable precise design innovation, allowing jewelers to experiment with complex geometries and customize pieces with enhanced accuracy. The integration of technology complements traditional methods by accelerating prototyping and expanding creative possibilities while preserving the essence of handcrafted detail.

Quality Assurance: Handmade vs Technological Precision

Traditional craftsmanship in jewelry making emphasizes meticulous handwork that ensures unique detail and artisanal value, often reflected in subtle imperfections that signify authenticity. Technological integration enhances quality assurance through precise measurements, consistent replication, and error reduction using CAD software and laser cutting tools. Combining handmade techniques with advanced technology optimizes durability and design accuracy, elevating overall product excellence.

Customization: Personal Touch vs Automated Solutions

Traditional craftsmanship in jewelry making offers unparalleled customization through meticulous handwork, allowing artisans to infuse unique personal touches and intricate details into each piece. Technology integration introduces automated solutions like 3D printing and CAD design, enabling precise replication and faster production while maintaining a high level of customization. Balancing these methods enhances the creation of personalized jewelry that combines artisanal uniqueness with technological efficiency.

Sustainability and Ethical Considerations

Traditional craftsmanship in jewelry making preserves artisanal skills while often relying on sustainable, locally sourced materials that reduce environmental impact. Technology integration enhances precision and efficiency, enabling the use of recycled metals and conflict-free gemstones, which supports ethical sourcing and sustainability goals. Combining these approaches promotes eco-friendly practices and maintains cultural heritage within the jewelry industry.

Market Trends: Consumer Preferences in the Digital Age

Traditional craftsmanship in jewelry making emphasizes artisanal skills and unique, handcrafted designs that appeal to consumers seeking authenticity and heritage. Technology integration, such as 3D printing and computer-aided design (CAD), enables mass customization, faster production, and innovative styles that attract tech-savvy buyers. Market trends reveal a growing consumer preference for personalized jewelry that combines the artistry of traditional techniques with the efficiency and precision of modern technology.

The Future of Jewelry Making: Balancing Craft and Innovation

Traditional craftsmanship in jewelry making preserves intricate handwork and artisanal techniques passed down through generations, ensuring unique and high-quality pieces. Technology integration, such as 3D printing and CAD design, enhances precision, customization, and efficiency in production. Balancing these approaches shapes the future of jewelry making by combining timeless artistry with cutting-edge innovation to meet evolving consumer demands.

Traditional craftsmanship vs Technology integration Infographic

bizdif.com

bizdif.com