Jewelers saws provide precise manual control for intricate designs and delicate cuts, ideal for custom or small-scale jewelry making. Laser cutting offers high-speed, consistent accuracy suitable for detailed patterns and mass production, especially with complex shapes or hard-to-cut materials. Choosing between the two methods depends on the desired craftsmanship level, production volume, and material type.

Table of Comparison

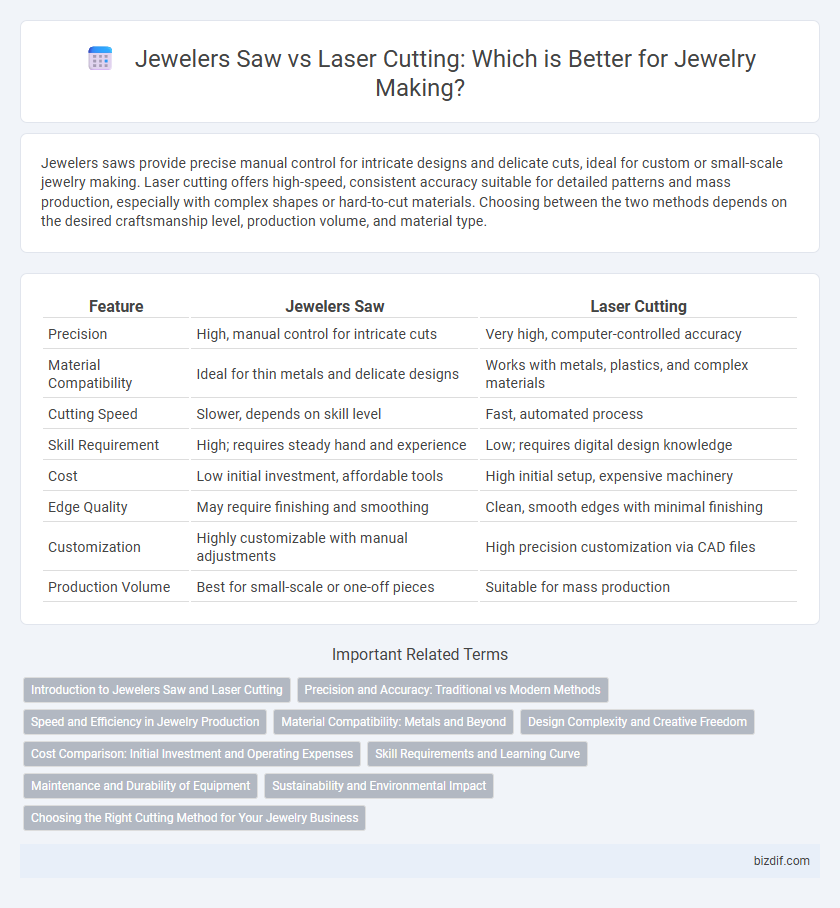

| Feature | Jewelers Saw | Laser Cutting |

|---|---|---|

| Precision | High, manual control for intricate cuts | Very high, computer-controlled accuracy |

| Material Compatibility | Ideal for thin metals and delicate designs | Works with metals, plastics, and complex materials |

| Cutting Speed | Slower, depends on skill level | Fast, automated process |

| Skill Requirement | High; requires steady hand and experience | Low; requires digital design knowledge |

| Cost | Low initial investment, affordable tools | High initial setup, expensive machinery |

| Edge Quality | May require finishing and smoothing | Clean, smooth edges with minimal finishing |

| Customization | Highly customizable with manual adjustments | High precision customization via CAD files |

| Production Volume | Best for small-scale or one-off pieces | Suitable for mass production |

Introduction to Jewelers Saw and Laser Cutting

Jeweler's saws provide precise manual control for intricate metal cutting, ideal for detailed and custom jewelry designs. Laser cutting offers high-speed, automated precision with minimal material waste, suitable for complex patterns and mass production. Both techniques enhance craftsmanship by enabling fine shaping and intricate detailing in jewelry making.

Precision and Accuracy: Traditional vs Modern Methods

Jewelers saw offers tactile control and intricate detail for handcrafted precision, ideal for delicate designs requiring personalized adjustments. Laser cutting delivers unmatched accuracy with computer-guided precision, enabling complex patterns and consistent replication in mass production. The choice depends on whether artisans prioritize hands-on craftsmanship or efficient, high-precision modern technology.

Speed and Efficiency in Jewelry Production

Jewelers saw offers precise control for intricate designs but is considerably slower, limiting efficiency in high-volume jewelry production. Laser cutting significantly enhances speed, enabling rapid and consistent cutting of complex patterns with minimal manual intervention. The advanced automation of laser cutting streamlines workflow, reducing production time and boosting overall output in jewelry manufacturing.

Material Compatibility: Metals and Beyond

Jewelers saws excel in cutting precious metals like gold, silver, and platinum with precision and control, making them ideal for delicate jewelry designs. Laser cutting technology extends compatibility beyond metals, efficiently slicing through materials such as acrylic, wood, and leather while maintaining intricate detail. Both methods offer unique advantages depending on material type, thickness, and the desired finish in jewelry making.

Design Complexity and Creative Freedom

Jewelers saw enables intricate hand-cut designs with precise control over fine details, offering unparalleled creative freedom and customization for unique jewelry pieces. Laser cutting excels in producing highly complex patterns with extreme accuracy and uniformity, especially useful for replicating detailed designs at scale. While jewelers saw empowers artisans to experiment with subtle variations, laser cutting provides consistency and the ability to execute intricate geometries impossible to achieve manually.

Cost Comparison: Initial Investment and Operating Expenses

Jewelers saws require a low initial investment, typically under $50 for basic tools, while laser cutting systems demand a substantial upfront cost exceeding $10,000. Operating expenses for jewelers saws remain minimal, mostly involving blade replacements at a few dollars each, whereas laser cutting machines incur higher costs due to maintenance, electricity consumption, and occasional parts replacement. Cost efficiency favors jewelers saws for small-scale or hobbyist projects, while laser cutting justifies its expense in larger, precision-demanding commercial productions.

Skill Requirements and Learning Curve

Jewelers saw demands intricate hand-eye coordination and steady hands, requiring extensive practice to master blade control and precision cutting for detailed designs. Laser cutting offers a faster learning curve with computer-guided precision, relying more on software proficiency than manual dexterity. Mastery of jewelers saw develops traditional craftsmanship skills, while laser cutting emphasizes technological competence and design software operation.

Maintenance and Durability of Equipment

Jewelers saws require regular blade replacement and careful tension adjustment to maintain precision, often demanding more hands-on maintenance compared to laser cutting machines. Laser cutting equipment boasts durable components like sealed lenses and high-quality optics, reducing wear and extending service intervals. Maintenance for laser cutters focuses on cooling systems and software updates, contributing to consistent performance and long-term durability.

Sustainability and Environmental Impact

Jewelers saw cutting generates minimal waste through precise manual control, promoting sustainability by reducing material loss and energy consumption. Laser cutting, while enabling intricate designs with high efficiency, relies on electricity often sourced from non-renewable resources, increasing carbon emissions. Choosing traditional saw techniques supports eco-friendly practices by minimizing the environmental footprint associated with jewelry production.

Choosing the Right Cutting Method for Your Jewelry Business

Choosing between a jeweler's saw and laser cutting depends on the complexity, precision, and volume of your jewelry production. A jeweler's saw offers hands-on control and is ideal for intricate, small-scale designs, while laser cutting delivers high precision and speed suitable for mass production and detailed patterns. Evaluating project requirements, budget constraints, and desired finish quality ensures selecting the optimal cutting method for your jewelry business success.

Jewelers saw vs laser cutting Infographic

bizdif.com

bizdif.com