Wax carving offers unparalleled control and tactile feedback for intricate jewelry designs, allowing artisans to shape detailed patterns by hand. 3D printing accelerates the prototyping process with precision and repeatability, enabling complex structures that might be challenging to achieve manually. Choosing between wax carving and 3D printing depends on the desired balance of traditional craftsmanship and modern efficiency in jewelry making.

Table of Comparison

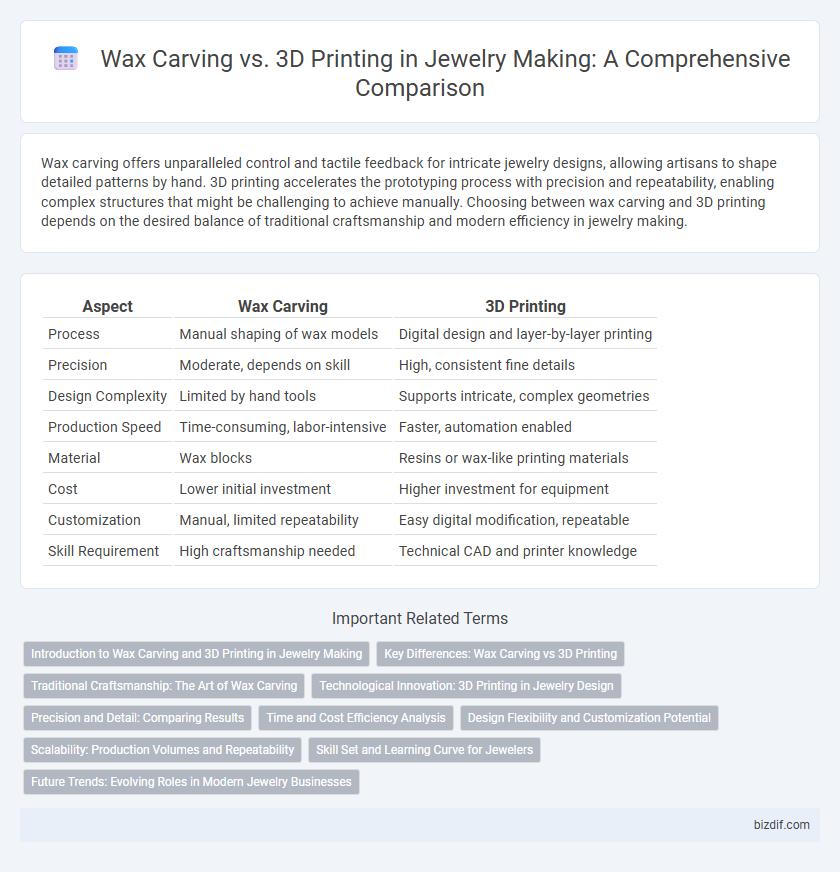

| Aspect | Wax Carving | 3D Printing |

|---|---|---|

| Process | Manual shaping of wax models | Digital design and layer-by-layer printing |

| Precision | Moderate, depends on skill | High, consistent fine details |

| Design Complexity | Limited by hand tools | Supports intricate, complex geometries |

| Production Speed | Time-consuming, labor-intensive | Faster, automation enabled |

| Material | Wax blocks | Resins or wax-like printing materials |

| Cost | Lower initial investment | Higher investment for equipment |

| Customization | Manual, limited repeatability | Easy digital modification, repeatable |

| Skill Requirement | High craftsmanship needed | Technical CAD and printer knowledge |

Introduction to Wax Carving and 3D Printing in Jewelry Making

Wax carving in jewelry making involves sculpting detailed designs directly into blocks of wax, providing high precision and tactile control for custom pieces. 3D printing uses digital models to produce intricate wax or resin forms with swift accuracy, enabling complex geometries difficult to achieve by hand. Both techniques serve as essential steps in the lost-wax casting process, transforming designs into precious metal jewelry.

Key Differences: Wax Carving vs 3D Printing

Wax carving involves manually shaping a wax block to create intricate jewelry designs, offering tactile precision and traditional craftsmanship. In contrast, 3D printing uses digital modeling to produce highly detailed and complex patterns with consistent accuracy and faster turnaround times. The key differences lie in customization flexibility, time efficiency, and the balance between artisanal skill versus technological automation in jewelry making.

Traditional Craftsmanship: The Art of Wax Carving

Wax carving remains a revered technique in jewelry making, showcasing the artisan's precise skill in shaping intricate designs by hand. This traditional craftsmanship allows for exceptional detail and customization, giving each piece a unique character that 3D printing often struggles to replicate. The tactile connection and nuanced control in wax carving create timeless jewelry art that blends creativity with expert craftsmanship.

Technological Innovation: 3D Printing in Jewelry Design

3D printing revolutionizes jewelry design by enabling intricate and precise wax models that surpass traditional hand-carved methods in speed and complexity. This technology allows designers to create highly detailed prototypes with minimal material waste and faster turnaround times, enhancing production efficiency. Advanced software integration in 3D printing further facilitates customization and iterative design, positioning it as a crucial innovation in modern jewelry making.

Precision and Detail: Comparing Results

Wax carving offers incredible tactile precision, allowing jewelers to manually refine intricate details and achieve organic textures that are often difficult to replicate digitally. In contrast, 3D printing delivers exceptional accuracy through computer-controlled processes, enabling consistent reproduction of complex designs with fine resolution down to microns. While wax carving excels in artistic nuance, 3D printing ensures high-detail consistency and efficiency, making both techniques valuable depending on the project's precision demands.

Time and Cost Efficiency Analysis

Wax carving traditionally requires skilled artisans and can be time-consuming, often extending production timelines and increasing labor costs. In contrast, 3D printing streamlines the process by rapidly producing precise wax models, reducing manual labor and overall production time significantly. This technological shift enhances cost efficiency by minimizing material waste and accelerating prototype iterations, making 3D printing a preferred choice for modern jewelry manufacturing.

Design Flexibility and Customization Potential

Wax carving offers tactile precision and organic detail, allowing artisans to sculpt intricate designs with hands-on control, ideal for unique, handcrafted jewelry pieces. 3D printing excels in producing highly complex geometries and uniformity, enabling rapid prototyping and easy modifications for mass customization. Combining both methods enhances design flexibility and customization potential, leveraging the strengths of manual craftsmanship and advanced digital technology.

Scalability: Production Volumes and Repeatability

Wax carving offers limited scalability due to its labor-intensive, handcrafted nature, making it suitable for low production volumes and unique pieces. In contrast, 3D printing enables high scalability with consistent repeatability, allowing manufacturers to produce large production volumes efficiently and maintain uniform quality across all items. The digital precision of 3D printing significantly reduces variability, enhancing the reliability of mass-produced jewelry components.

Skill Set and Learning Curve for Jewelers

Wax carving requires traditional handcrafting skills, precision, and steady hands developed through practice, making it ideal for jewelers with experience in manual techniques. 3D printing utilizes digital modeling software, demanding technical proficiency in CAD design and machine operation, which can be quickly learned by tech-savvy jewelers. The learning curve for wax carving is steep due to the need for mastering intricate hand skills, while 3D printing offers a more accessible entry point, especially for those familiar with digital tools.

Future Trends: Evolving Roles in Modern Jewelry Businesses

Wax carving remains a foundational skill in traditional jewelry making, valued for its tactile precision and artisanal touch, while 3D printing accelerates design innovation through rapid prototyping and complex geometries. Future trends indicate a hybrid approach where modern jewelry businesses integrate both methods, maximizing creative flexibility and production efficiency. Advancements in 3D printing materials and software continue to blur the lines between handcrafted artistry and digital fabrication, reshaping industry standards.

Wax carving vs 3D printing Infographic

bizdif.com

bizdif.com