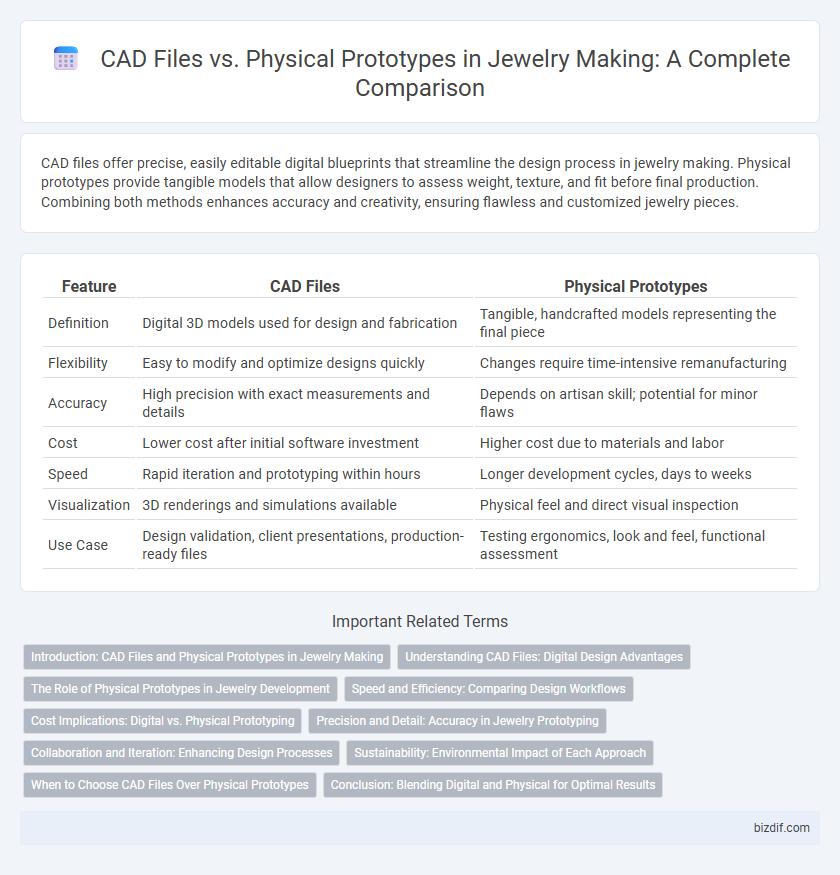

CAD files offer precise, easily editable digital blueprints that streamline the design process in jewelry making. Physical prototypes provide tangible models that allow designers to assess weight, texture, and fit before final production. Combining both methods enhances accuracy and creativity, ensuring flawless and customized jewelry pieces.

Table of Comparison

| Feature | CAD Files | Physical Prototypes |

|---|---|---|

| Definition | Digital 3D models used for design and fabrication | Tangible, handcrafted models representing the final piece |

| Flexibility | Easy to modify and optimize designs quickly | Changes require time-intensive remanufacturing |

| Accuracy | High precision with exact measurements and details | Depends on artisan skill; potential for minor flaws |

| Cost | Lower cost after initial software investment | Higher cost due to materials and labor |

| Speed | Rapid iteration and prototyping within hours | Longer development cycles, days to weeks |

| Visualization | 3D renderings and simulations available | Physical feel and direct visual inspection |

| Use Case | Design validation, client presentations, production-ready files | Testing ergonomics, look and feel, functional assessment |

Introduction: CAD Files and Physical Prototypes in Jewelry Making

CAD files in jewelry making enable precise digital designs, facilitating intricate detailing and easy modifications before production. Physical prototypes provide tangible models for assessing design aesthetics, fit, and comfort, offering critical insights that digital previews cannot capture. Combining CAD files with physical prototypes streamlines the design process, ensuring high-quality, customizable jewelry outcomes tailored to client specifications.

Understanding CAD Files: Digital Design Advantages

CAD files in jewelry making offer precise digital designs that allow for intricate detailing and easy modifications before production. These files streamline the design process, enabling faster prototyping and reducing material waste compared to physical prototypes. Utilizing CAD technology enhances accuracy and consistency, resulting in higher-quality final jewelry pieces.

The Role of Physical Prototypes in Jewelry Development

Physical prototypes in jewelry development provide tangible feedback on design accuracy, fit, and comfort that CAD files alone cannot fully capture. They enable jewelers to assess material behavior, surface details, and structural integrity before mass production, reducing costly errors. This hands-on evaluation complements digital modeling, ensuring that the final piece aligns precisely with aesthetic and functional requirements.

Speed and Efficiency: Comparing Design Workflows

CAD files streamline jewelry design by enabling rapid modifications and precise detailing without the need for physical materials, significantly reducing production time. Physical prototypes require manual crafting, which can slow down iteration cycles and increase material costs. Utilizing CAD technology accelerates the workflow, enhancing efficiency and allowing designers to focus on creative refinement.

Cost Implications: Digital vs. Physical Prototyping

CAD files significantly reduce costs by enabling precise digital modeling and easy modifications without material waste. Physical prototypes, while essential for tactile evaluation and fit, incur higher expenses due to raw materials, labor, and fabrication time. Investing in digital prototyping optimizes budget efficiency, especially during early design iterations.

Precision and Detail: Accuracy in Jewelry Prototyping

CAD files enable flawless precision in jewelry prototyping, capturing intricate design details down to microns that physical prototypes may not consistently achieve. The digital nature of CAD allows for exact measurements and flawless geometry, ensuring every component fits perfectly before production. Physical prototypes, while tangible, often involve manual processes that can introduce slight variations, impacting the overall accuracy and detail of the final piece.

Collaboration and Iteration: Enhancing Design Processes

CAD files allow jewelry designers to share intricate digital models instantly, facilitating seamless collaboration across teams and clients worldwide. Physical prototypes provide tangible feedback, enabling hands-on evaluation and detailed adjustments that enhance the tactile and aesthetic qualities of the piece. Combining CAD files with physical prototypes accelerates iteration cycles, improving design accuracy and ensuring the final product meets both functional and artistic standards.

Sustainability: Environmental Impact of Each Approach

CAD files for jewelry making significantly reduce material waste compared to physical prototypes by enabling precise digital modeling and virtual adjustments. Physical prototypes, often requiring multiple rounds and substantial material use, generate more waste and energy consumption throughout fabrication and disposal. Digital workflows also lower carbon footprints by minimizing the need for shipping and storage of bulky prototype materials.

When to Choose CAD Files Over Physical Prototypes

CAD files in jewelry making offer precision and rapid modifications, making them ideal for early design iterations and detailed customization. They reduce material waste and production costs by allowing virtual testing of complex geometries before physical crafting. Opt for CAD files over physical prototypes when accuracy, efficiency, and flexibility in design changes are priorities during the concept development phase.

Conclusion: Blending Digital and Physical for Optimal Results

Combining CAD files with physical prototypes leverages the precision of digital design and the tactile accuracy of handcrafted models, ensuring superior jewelry craftsmanship. CAD files enable intricate detailing and rapid modifications, while physical prototypes provide tangible validation of fit, feel, and aesthetics. This integrated approach minimizes errors, accelerates production timelines, and enhances the overall quality of custom jewelry pieces.

CAD Files vs Physical Prototypes Infographic

bizdif.com

bizdif.com