Automated packing for pet meal prepping enhances efficiency and consistency by using machines to portion and package food, reducing human error and saving time. Manual packing allows for customization and careful inspection of each meal, ensuring specific dietary needs and preferences are met. Choosing between automated and manual packing depends on the scale of production and the balance between speed and personalized quality in pet nutrition.

Table of Comparison

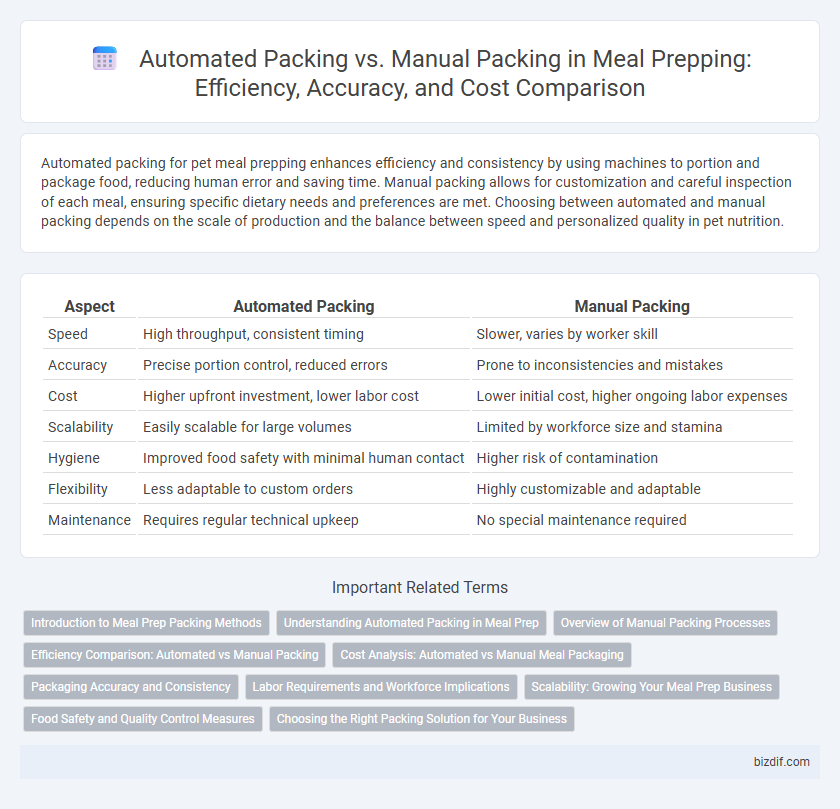

| Aspect | Automated Packing | Manual Packing |

|---|---|---|

| Speed | High throughput, consistent timing | Slower, varies by worker skill |

| Accuracy | Precise portion control, reduced errors | Prone to inconsistencies and mistakes |

| Cost | Higher upfront investment, lower labor cost | Lower initial cost, higher ongoing labor expenses |

| Scalability | Easily scalable for large volumes | Limited by workforce size and stamina |

| Hygiene | Improved food safety with minimal human contact | Higher risk of contamination |

| Flexibility | Less adaptable to custom orders | Highly customizable and adaptable |

| Maintenance | Requires regular technical upkeep | No special maintenance required |

Introduction to Meal Prep Packing Methods

Automated packing in meal prepping employs advanced machinery to portion and seal meals efficiently, ensuring consistent quality and reducing labor time. Manual packing relies on human hands to assemble ingredients, allowing for flexibility and customization but often increasing preparation time. Understanding these methods helps optimize workflow and meet specific dietary or business needs.

Understanding Automated Packing in Meal Prep

Automated packing in meal prep utilizes advanced machinery and robotics to efficiently portion, seal, and organize ingredients or meals with precision and consistency. This technology reduces human error, enhances speed, and maintains hygiene standards, making it ideal for large-scale meal preparation. Integrating automated systems can streamline workflows, lower labor costs, and improve packaging uniformity in commercial kitchens.

Overview of Manual Packing Processes

Manual packing in meal prepping involves physically sorting and portioning ingredients into containers by hand, allowing for precise customization and control over meal components. This process often requires careful measurement, labeling, and organization to ensure consistency and freshness across multiple meals. Despite being labor-intensive, manual packing offers flexibility for accommodating dietary restrictions and individual preferences without relying on automated systems.

Efficiency Comparison: Automated vs Manual Packing

Automated packing systems streamline meal prepping by significantly reducing labor time and minimizing errors, offering consistent portion control and faster throughput compared to manual packing. Manual packing, while more flexible for customization and intricate presentation, often results in slower processing speeds and higher chances of human error. Efficiency metrics reveal automated solutions improve packing speed by up to 50%, making them ideal for large-scale operations requiring uniformity and scalability.

Cost Analysis: Automated vs Manual Meal Packaging

Automated meal packaging systems require significant upfront investment in machinery but reduce long-term labor costs, increasing efficiency and consistency in portion control. Manual packing incurs lower initial expenses but demands higher ongoing labor costs, with increased risks of human error and slower throughput. Businesses must evaluate production volume and labor costs to determine whether automation offers a cost-effective solution compared to traditional manual meal prepping methods.

Packaging Accuracy and Consistency

Automated packing systems for meal prepping significantly enhance packaging accuracy by using precise measurements and standardized portion control, reducing human error. Consistency in portion sizes and sealing quality is achieved through programmed machinery, ensuring uniform packaging across large batches. Manual packing, while flexible, often results in variations due to individual differences, impacting both accuracy and consistency in meal portions.

Labor Requirements and Workforce Implications

Automated packing in meal prepping significantly reduces labor requirements by streamlining portioning and packaging tasks, allowing for faster processing and minimized human error. Manual packing demands more workforce involvement, increasing labor costs and the potential for inconsistencies in meal portions. Transitioning to automated systems can optimize staffing efficiency, enabling businesses to reallocate labor towards quality control and product innovation.

Scalability: Growing Your Meal Prep Business

Automated packing systems enable rapid scaling by significantly increasing meal preparation throughput while maintaining consistent portion control and packaging quality. Manual packing limits scalability due to labor-intensive processes and higher risks of human error, which can slow down order fulfillment and increase operational costs. Investing in automated solutions offers meal prep businesses the ability to efficiently handle larger volumes and expand market reach without sacrificing product consistency.

Food Safety and Quality Control Measures

Automated packing systems in meal prepping enhance food safety by minimizing human contact, reducing contamination risks, and ensuring consistent portion control through precise machinery calibration. Manual packing allows for tactile quality assessment and adaptability to irregular food shapes but increases the chances of human error and contamination without strict hygiene protocols. Implementing rigorous quality control measures such as sterilized equipment, standardized procedures, and temperature monitoring is crucial in both methods to maintain optimal food safety and product quality.

Choosing the Right Packing Solution for Your Business

Automated packing systems increase efficiency by reducing labor costs and minimizing human error, making them ideal for high-volume meal prepping businesses seeking consistent portion control and faster turnaround times. Manual packing offers greater flexibility and customization, suitable for small-scale operations or specialty meal services requiring personalized ingredient selection. Evaluating order volume, budget, and product variety helps determine the optimal packing solution to balance operational efficiency with quality control.

Automated Packing vs Manual Packing Infographic

bizdif.com

bizdif.com