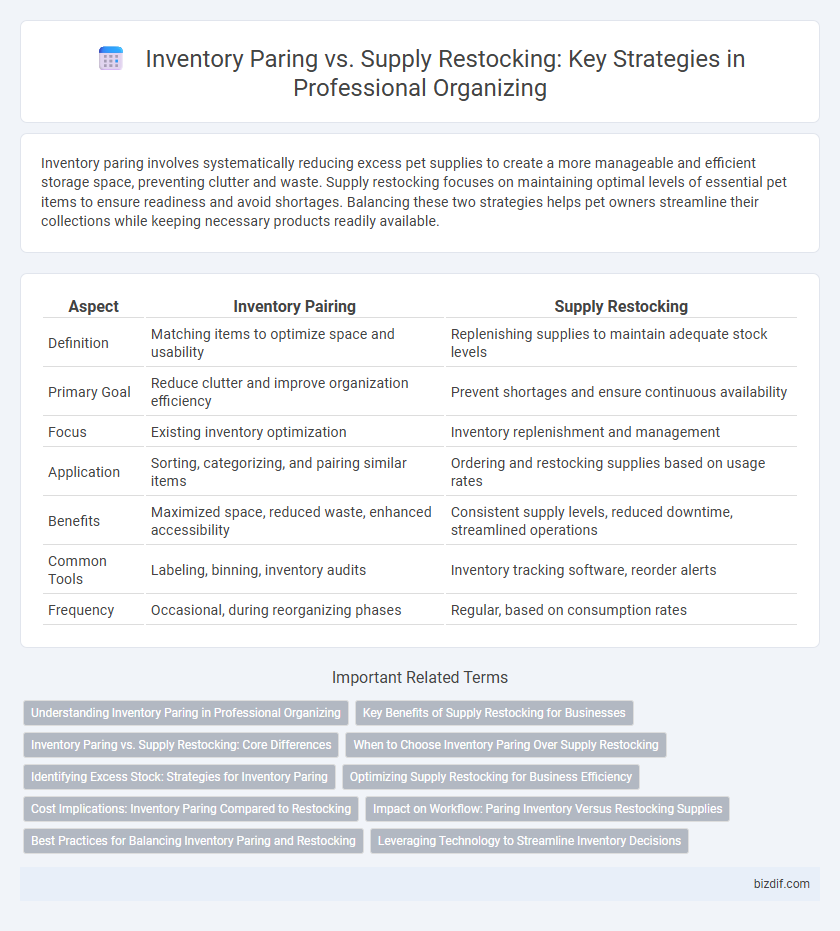

Inventory paring involves systematically reducing excess pet supplies to create a more manageable and efficient storage space, preventing clutter and waste. Supply restocking focuses on maintaining optimal levels of essential pet items to ensure readiness and avoid shortages. Balancing these two strategies helps pet owners streamline their collections while keeping necessary products readily available.

Table of Comparison

| Aspect | Inventory Pairing | Supply Restocking |

|---|---|---|

| Definition | Matching items to optimize space and usability | Replenishing supplies to maintain adequate stock levels |

| Primary Goal | Reduce clutter and improve organization efficiency | Prevent shortages and ensure continuous availability |

| Focus | Existing inventory optimization | Inventory replenishment and management |

| Application | Sorting, categorizing, and pairing similar items | Ordering and restocking supplies based on usage rates |

| Benefits | Maximized space, reduced waste, enhanced accessibility | Consistent supply levels, reduced downtime, streamlined operations |

| Common Tools | Labeling, binning, inventory audits | Inventory tracking software, reorder alerts |

| Frequency | Occasional, during reorganizing phases | Regular, based on consumption rates |

Understanding Inventory Paring in Professional Organizing

Inventory paring in professional organizing involves systematically reducing excess items to streamline spaces, enhance functionality, and prevent clutter buildup. This process contrasts with supply restocking, which focuses on maintaining necessary quantities of essential items for ongoing use. Understanding inventory paring helps organizers create balanced environments that optimize storage and improve client satisfaction by minimizing unnecessary possessions.

Key Benefits of Supply Restocking for Businesses

Supply restocking ensures businesses maintain optimal inventory levels, preventing stockouts and lost sales opportunities. It streamlines operations by reducing downtime due to missing supplies and enhances customer satisfaction through consistent product availability. Efficient supply restocking supports accurate demand forecasting and cost savings by minimizing emergency orders and excess stock.

Inventory Paring vs. Supply Restocking: Core Differences

Inventory paring focuses on reducing excess items to streamline space and improve efficiency, while supply restocking ensures necessary materials are replenished to maintain functionality. Professional organizing emphasizes inventory paring to eliminate clutter, contrasting with supply restocking's goal of sustaining inventory levels. Understanding these core differences aids in optimizing organizational systems and maintaining balance between surplus and essential supplies.

When to Choose Inventory Paring Over Supply Restocking

Inventory paring is ideal when assessing excess stock that clutters storage, promotes inefficiency, or involves outdated or unused items in professional organizing settings. This approach streamlines inventory by removing unnecessary supplies, enhancing space utilization and reducing carrying costs. Opt for supply restocking only when essential items are depleted or demand increases, ensuring optimal stock levels without contributing to overstock problems.

Identifying Excess Stock: Strategies for Inventory Paring

Identifying excess stock in professional organizing involves systematic assessment of inventory turnover rates and product demand patterns to pinpoint surplus items. Utilizing data-driven techniques such as ABC analysis and real-time inventory tracking ensures precise paring of overstocked supplies, reducing storage costs and preventing resource wastage. Implementing these strategies enhances operational efficiency by aligning supply levels with actual consumption trends, optimizing inventory management.

Optimizing Supply Restocking for Business Efficiency

Optimizing supply restocking enhances business efficiency by maintaining accurate inventory levels and reducing stockouts that disrupt operations. Implementing automated tracking systems ensures timely reorder alerts aligned with consumption rates, minimizing excess stock and storage costs. Strategic restocking integrates seamlessly with demand forecasting, enabling businesses to allocate resources effectively and sustain productivity.

Cost Implications: Inventory Paring Compared to Restocking

Inventory paring minimizes holding costs by reducing excess stock and preventing obsolete items, leading to more efficient cash flow management. Supply restocking incurs immediate expenses for purchasing and replenishment while risking overstock and tied-up capital. Strategic inventory paring enhances cost savings by optimizing stock levels and lowering storage and depreciation expenses compared to frequent restocking cycles.

Impact on Workflow: Paring Inventory Versus Restocking Supplies

Paring inventory streamlines workflow by minimizing clutter and reducing time spent searching for items, enhancing overall efficiency in professional organizing. Restocking supplies ensures continuous availability of essential materials but can lead to workflow interruptions if not managed proactively. Balancing inventory paring with strategic restocking optimizes task flow and maintains an organized workspace.

Best Practices for Balancing Inventory Paring and Restocking

Effective professional organizing requires balancing inventory paring and supply restocking to maintain optimal order and functionality. Implement systematic audits to identify excess items for paring while simultaneously tracking usage patterns to determine timely restocking needs. Leveraging digital inventory tools enhances accuracy and efficiency, ensuring spaces remain clutter-free and well-stocked without overaccumulation.

Leveraging Technology to Streamline Inventory Decisions

Leveraging technology in professional organizing enhances inventory pairing by using AI-driven analytics to match current supplies with project demands, reducing excess and waste. Digital inventory management systems automate supply restocking alerts based on real-time usage data, ensuring timely replenishment without overstocking. Integrating smart tools streamlines decision-making processes, optimizing both inventory accuracy and supply chain efficiency.

inventory paring vs supply restocking Infographic

bizdif.com

bizdif.com