Lean office methods prioritize efficiency by eliminating unnecessary tasks and streamlining workflows, which differs from traditional organizing that often focuses on categorizing items without assessing their actual use. This approach reduces clutter by encouraging only essential materials, improving productivity and reducing stress. Implementing lean principles in pet-related professional organizing leads to a more functional workspace tailored to real-time needs rather than static storage.

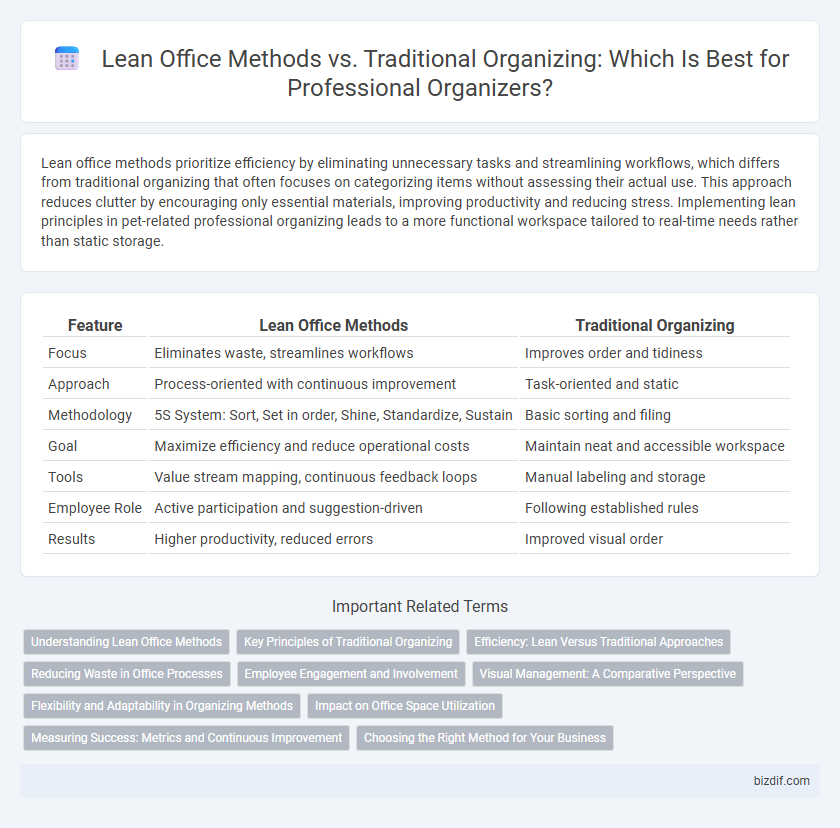

Table of Comparison

| Feature | Lean Office Methods | Traditional Organizing |

|---|---|---|

| Focus | Eliminates waste, streamlines workflows | Improves order and tidiness |

| Approach | Process-oriented with continuous improvement | Task-oriented and static |

| Methodology | 5S System: Sort, Set in order, Shine, Standardize, Sustain | Basic sorting and filing |

| Goal | Maximize efficiency and reduce operational costs | Maintain neat and accessible workspace |

| Tools | Value stream mapping, continuous feedback loops | Manual labeling and storage |

| Employee Role | Active participation and suggestion-driven | Following established rules |

| Results | Higher productivity, reduced errors | Improved visual order |

Understanding Lean Office Methods

Lean office methods streamline workflows by eliminating waste and optimizing value-added activities, leading to increased efficiency and reduced operational costs. Unlike traditional organizing, which often focuses on sorting and categorizing, Lean emphasizes continuous improvement, standardization, and visual management tools such as Kanban boards and 5S principles. Implementing Lean office techniques enhances productivity by minimizing delays, improving task clarity, and fostering a culture of collaboration and accountability.

Key Principles of Traditional Organizing

Traditional organizing centers on systematic categorization, prioritizing physical file management and clearly defined storage spaces to enhance accessibility. It emphasizes decluttering through sorting and purging, creating order by grouping similar items and labeling for straightforward retrieval. Unlike Lean office methods that focus on continuous process improvement, traditional organizing relies on fixed structures and consistent maintenance routines to sustain office productivity.

Efficiency: Lean Versus Traditional Approaches

Lean office methods streamline workflows by minimizing waste and optimizing processes, resulting in faster task completion and improved resource utilization. Traditional organizing often relies on fixed structures and predefined routines, which can create bottlenecks and reduce overall efficiency. Lean approaches emphasize continuous improvement and adaptability, enabling office environments to respond swiftly to changing demands while maintaining high productivity.

Reducing Waste in Office Processes

Lean office methods reduce waste by streamlining workflows, eliminating redundant steps, and prioritizing value-added activities, leading to increased efficiency and productivity. Traditional organizing often involves compartmentalizing tasks without addressing process inefficiencies, which can result in clutter and time-consuming retrievals. Implementing Lean principles targets waste reduction in paperwork, wait times, and excess inventory to optimize office operations.

Employee Engagement and Involvement

Lean office methods prioritize continuous improvement and empower employees to identify inefficiencies, fostering higher engagement and ownership compared to traditional organizing, which often relies on top-down directives. By involving staff in streamlining processes and reducing waste, Lean techniques create a culture of collaboration and proactive problem-solving. This inclusive approach not only improves productivity but also boosts morale and job satisfaction among employees.

Visual Management: A Comparative Perspective

Lean office methods utilize Visual Management by employing color-coded tools, clear labeling, and real-time status boards to streamline workflow and reduce waste, enhancing transparency and efficiency. Traditional organizing often relies on static filing systems and manual sorting, which may lack immediate visibility and dynamic updates crucial for rapid decision-making. Emphasizing standardized visual cues in Lean approaches facilitates quicker information processing and continuous improvement, setting it apart from conventional methods that prioritize physical order over process optimization.

Flexibility and Adaptability in Organizing Methods

Lean office methods emphasize flexibility and adaptability through continuous process evaluation and waste reduction, enabling dynamic adjustments to workflow and workspace organization. Traditional organizing relies on fixed, predefined structures that may hinder rapid changes and limit responsiveness to evolving business needs. Prioritizing lean techniques fosters a more agile office environment, promoting efficiency and scalability in professional organizing.

Impact on Office Space Utilization

Lean office methods enhance space utilization by streamlining workflows and eliminating unnecessary items, which maximizes available workspace and reduces clutter. Traditional organizing often emphasizes categorization and storage without addressing process inefficiencies, leading to underutilized areas and overcrowded desks. Implementing lean principles results in a more efficient layout that supports productivity by optimizing the use of every square foot in the office.

Measuring Success: Metrics and Continuous Improvement

Lean office methods prioritize key performance indicators such as cycle time, waste reduction, and productivity gains to measure success, contrasting traditional organizing that often relies on subjective assessments. Continuous improvement in lean offices uses real-time data and employee feedback loops to refine processes, ensuring measurable efficiency improvements. This data-driven approach fosters sustainable improvements and quantifiable outcomes, unlike traditional methods that may lack structured metrics.

Choosing the Right Method for Your Business

Lean office methods emphasize eliminating waste, streamlining workflows, and enhancing productivity by focusing on value-added tasks, making them ideal for businesses seeking efficiency and agility. Traditional organizing centers on systematic categorization and storage, which can support businesses that prioritize comprehensive documentation and long-term access to information. Selecting the right method depends on business goals, with lean practices suited for dynamic, process-oriented environments and traditional methods better for those requiring structured, static organization.

Lean office methods vs traditional organizing Infographic

bizdif.com

bizdif.com