Batch saponification involves mixing oils and lye in discrete batches, allowing for greater control over ingredient ratios and customization, ideal for artisanal pet soap production. Continuous saponification operates by feeding raw materials continuously through a reactor, offering higher efficiency and consistent quality for large-scale pet soap manufacturing. Choosing between batch and continuous saponification depends on production volume, customization needs, and operational scalability in pet soap making.

Table of Comparison

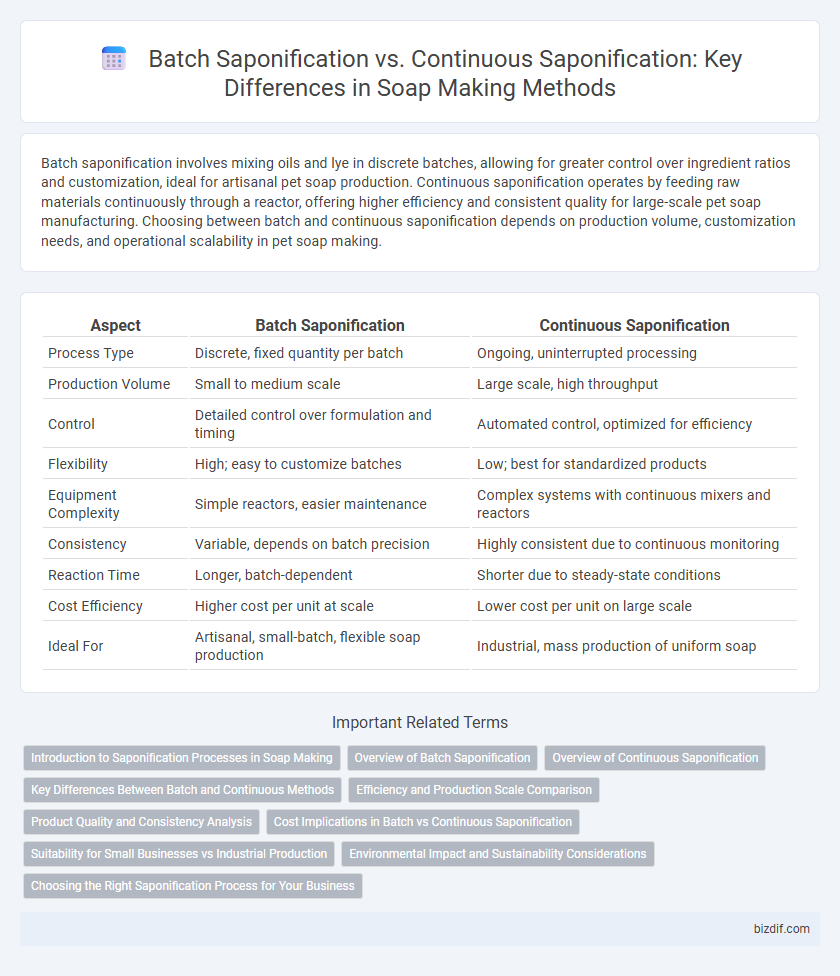

| Aspect | Batch Saponification | Continuous Saponification |

|---|---|---|

| Process Type | Discrete, fixed quantity per batch | Ongoing, uninterrupted processing |

| Production Volume | Small to medium scale | Large scale, high throughput |

| Control | Detailed control over formulation and timing | Automated control, optimized for efficiency |

| Flexibility | High; easy to customize batches | Low; best for standardized products |

| Equipment Complexity | Simple reactors, easier maintenance | Complex systems with continuous mixers and reactors |

| Consistency | Variable, depends on batch precision | Highly consistent due to continuous monitoring |

| Reaction Time | Longer, batch-dependent | Shorter due to steady-state conditions |

| Cost Efficiency | Higher cost per unit at scale | Lower cost per unit on large scale |

| Ideal For | Artisanal, small-batch, flexible soap production | Industrial, mass production of uniform soap |

Introduction to Saponification Processes in Soap Making

Batch saponification involves mixing fats and alkali in a single tank, allowing precise control over reaction time and temperature for artisanal soap production. Continuous saponification uses a steady flow of raw materials through reactors, enabling large-scale, efficient soap manufacturing with consistent product quality. Understanding these methods helps optimize soap properties and production scalability in different soap making operations.

Overview of Batch Saponification

Batch saponification involves producing soap by mixing fats and alkalis in discrete, controlled quantities within a single vessel, allowing precise monitoring of reaction parameters such as temperature and mixing speed. This method offers flexibility for small to medium-scale production and customization of soap formulations, ensuring consistent quality with each batch. Batch processes typically result in longer production cycles compared to continuous saponification but provide advantages in handling diverse raw materials and experimental formulations.

Overview of Continuous Saponification

Continuous saponification involves an ongoing, automated process where raw materials are continuously fed into the reactor and soap is concurrently produced and removed, ensuring consistent product quality and higher production efficiency. This method utilizes advanced controls to maintain optimal temperature and mixing conditions, resulting in uniform soap characteristics and reduced labor costs. Continuous saponification is favored in large-scale industrial soap manufacturing due to its scalability and ability to sustain uninterrupted operations.

Key Differences Between Batch and Continuous Methods

Batch saponification involves processing fixed quantities of oils and alkalis in separate, discrete batches, allowing precise control over reaction time and temperature, which enhances product consistency and quality. Continuous saponification operates with a constant flow of raw materials through reactors, optimizing production efficiency and scalability but requiring more complex equipment and control systems. Key differences lie in production scale, process control, equipment complexity, and the ability to rapidly adjust formulations between batches in batch processing versus uninterrupted operation in continuous methods.

Efficiency and Production Scale Comparison

Batch saponification offers greater control and flexibility, making it ideal for small to medium-scale soap production with varied formulations. Continuous saponification excels in efficiency and consistency, significantly increasing output for large-scale, industrial soap manufacturing by maintaining a steady and automated process. The choice between these methods depends on production volume demands and the need for formulation customization.

Product Quality and Consistency Analysis

Batch saponification offers precise control over reaction conditions, resulting in high product quality with consistent texture and scent in small-scale soap production. Continuous saponification enables large-scale manufacturing with consistent composition and uniformity due to steady-state processing but may face challenges in adjusting parameters for diverse formulations. Analyzing product quality, batch methods excel in customization, while continuous systems ensure reproducibility and efficiency across extensive production runs.

Cost Implications in Batch vs Continuous Saponification

Batch saponification typically incurs higher labor and energy costs due to its intermittent operation and frequent cleaning cycles, increasing overall production expenses. Continuous saponification, while requiring significant initial capital investment for specialized equipment, reduces operational costs through improved efficiency and consistent output. Economies of scale favor continuous processes, making them more cost-effective for large-scale soap manufacturing.

Suitability for Small Businesses vs Industrial Production

Batch saponification is ideal for small businesses due to its flexibility, ease of control, and ability to produce diverse soap formulations in smaller quantities. Continuous saponification suits industrial production by enabling high-volume output, consistent product quality, and efficient resource use through automated and steady processing. Small-scale artisans benefit from batch processes that prioritize customization, while large manufacturers rely on continuous systems for scalability and cost-effectiveness.

Environmental Impact and Sustainability Considerations

Batch saponification generates higher wastewater volumes due to intermittent processing, increasing the need for effective effluent treatment to minimize environmental harm. Continuous saponification improves resource efficiency by using steady-state reactions, reducing energy consumption and waste production per unit of soap manufactured. Choosing continuous systems enhances sustainability through consistent waste management and lower carbon footprints in industrial soap production.

Choosing the Right Saponification Process for Your Business

Batch saponification offers precise control over temperature and reaction time, making it ideal for small-scale or artisanal soap production where quality customization is essential. Continuous saponification maximizes efficiency and consistency, suitable for large-scale manufacturers aiming to optimize throughput and reduce labor costs. Selecting the right process depends on your production volume, desired product consistency, and operational flexibility, with batch favoring versatility and continuous excelling in scalability.

Batch Saponification vs Continuous Saponification Infographic

bizdif.com

bizdif.com