The CP swirl technique in soap making offers greater control over design details due to its faster setting time compared to the HP swirl technique, which allows for more vibrant colors and intricate patterns through a longer curing process. Cold process soaps require precise temperature management for successful swirls, while hot process soaps provide a textured, rustic look because the soap batter is cooked before swirling. Both methods enable creative expression in pet-themed soaps, with CP yielding smoother finishes and HP offering enhanced durability.

Table of Comparison

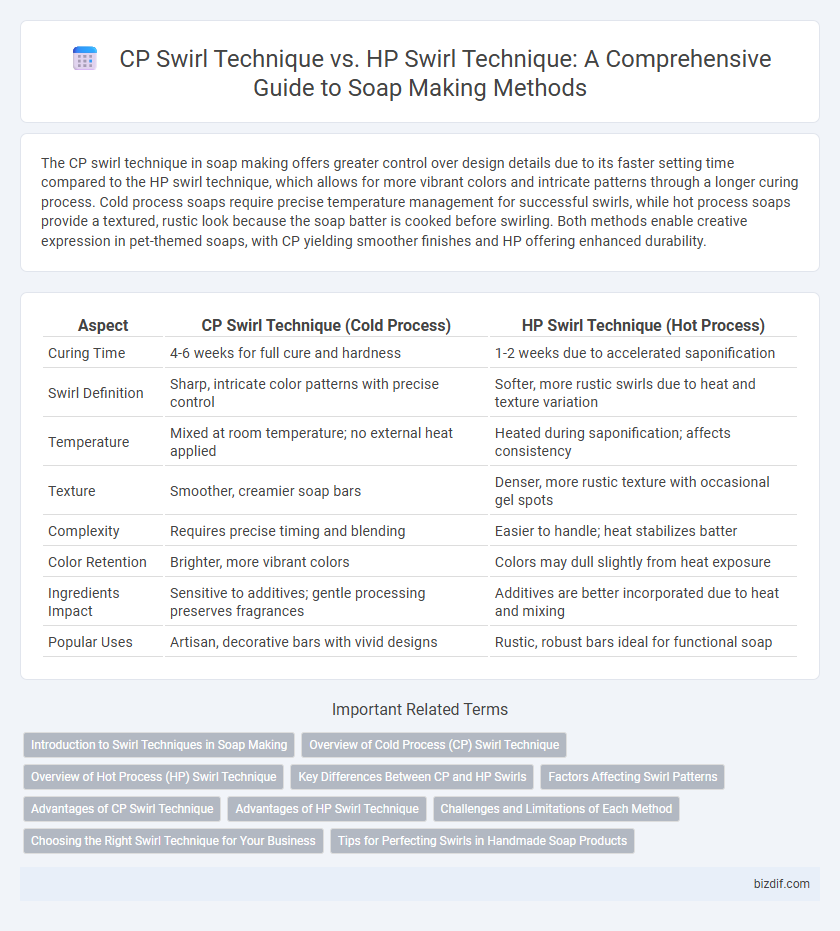

| Aspect | CP Swirl Technique (Cold Process) | HP Swirl Technique (Hot Process) |

|---|---|---|

| Curing Time | 4-6 weeks for full cure and hardness | 1-2 weeks due to accelerated saponification |

| Swirl Definition | Sharp, intricate color patterns with precise control | Softer, more rustic swirls due to heat and texture variation |

| Temperature | Mixed at room temperature; no external heat applied | Heated during saponification; affects consistency |

| Texture | Smoother, creamier soap bars | Denser, more rustic texture with occasional gel spots |

| Complexity | Requires precise timing and blending | Easier to handle; heat stabilizes batter |

| Color Retention | Brighter, more vibrant colors | Colors may dull slightly from heat exposure |

| Ingredients Impact | Sensitive to additives; gentle processing preserves fragrances | Additives are better incorporated due to heat and mixing |

| Popular Uses | Artisan, decorative bars with vivid designs | Rustic, robust bars ideal for functional soap |

Introduction to Swirl Techniques in Soap Making

The CP swirl technique, or cold process, involves manipulating soap batter before it hardens to create intricate patterns using multiple colors. The HP swirl technique, known as hot process, uses heat to speed up saponification, resulting in a denser texture and slightly different swirl effect compared to cold process. Both techniques offer unique artistic possibilities, with CP allowing more time for detailed designs and HP providing a rustic, textured finish.

Overview of Cold Process (CP) Swirl Technique

The Cold Process (CP) swirl technique involves pouring different colors of soap batter into the mold before swirling them together using tools like chopsticks or skewer sticks, creating intricate and unique marbled patterns. This method allows for greater control over the design because the soap batter thickens slowly, providing ample time to manipulate the swirls without premature setting. Cold Process soap maintain natural glycerin and allows custom formulation of ingredients, giving artisans versatility and high-quality soap bars.

Overview of Hot Process (HP) Swirl Technique

The Hot Process (HP) swirl technique in soap making involves cooking the soap mixture to accelerate saponification, resulting in a thicker batter perfect for creating vibrant, controlled swirls. Unlike the Cold Process (CP) swirl technique, HP allows for immediate use of the soap without a lengthy curing period, producing rustic, textured designs with enhanced color separation. The HP method's higher temperature and thicker consistency enable intricate, marbled patterns ideal for artisan soap bars with rich, creamy textures.

Key Differences Between CP and HP Swirls

Cold Process (CP) swirl technique involves mixing lye and oils at room temperature, allowing greater control over intricate designs and vibrant, long-lasting colors. Hot Process (HP) swirl technique uses heat to accelerate saponification, resulting in a thicker batter that yields more rustic, textured swirls with less color differentiation. Key differences include curing time--CP requires longer curing versus the shorter HP--and the level of detail achievable due to the varying soap batter consistencies.

Factors Affecting Swirl Patterns

Swirl patterns in cold process (CP) soap making are influenced by factors such as batter thickness, pouring temperature, and mixing speed, where a thicker batter and lower temperature create distinct, well-defined swirls. In hot process (HP) soap, the gel phase and faster trace due to elevated heat impact the swirl's fluidity and blending, often producing softer, less intricate patterns. The choice of colorants and pouring method also plays a critical role, with denser pigments and controlled pour heights enhancing visual contrast and swirl precision.

Advantages of CP Swirl Technique

Cold Process (CP) swirl technique offers greater control over design precision and color separation due to its slower saponification process compared to Hot Process (HP) swirl technique. This method allows for intricate patterns with vibrant, well-defined swirls since the soap batter remains pliable longer before curing. CP swirl technique also retains more fragrance and natural ingredients, enhancing the soap's aesthetic and therapeutic qualities.

Advantages of HP Swirl Technique

The HP Swirl Technique offers superior control over the color placement and pattern intricacy due to its longer curing process, allowing for more detailed and vibrant designs compared to the CP Swirl Technique. High-Performance (HP) soap's heat retention improves saponification uniformity, resulting in a smoother texture and enhanced durability. Artisans benefit from the extended working time and the ability to incorporate complex swirls without compromising the soap's structural integrity.

Challenges and Limitations of Each Method

The CP swirl technique demands precise timing and rapid pouring to prevent soap batter from thickening, posing challenges for beginners due to its quick saponification process and limited working time. In contrast, the HP swirl technique involves a longer gel phase and curing period, which can lead to unpredictable color blending and a greater risk of batter overheating, affecting the final design clarity. Both methods require careful temperature control and advanced skill levels to achieve desired swirl patterns without compromising soap quality.

Choosing the Right Swirl Technique for Your Business

Choosing the right swirl technique for your soap business depends on production scale and design complexity; the Cold Process (CP) swirl technique offers vibrant, intricate patterns but requires precise timing and temperature control, ideal for artisanal, small-batch creations. The Hot Process (HP) swirl technique, by contrast, allows faster curing and easier handling of soap batter, making it suitable for larger batches and retailers prioritizing durability and efficiency. Evaluating your business goals, resources, and desired aesthetic will determine whether CP's detailed artistry or HP's streamlined process aligns better with your production needs and market demands.

Tips for Perfecting Swirls in Handmade Soap Products

Mastering the CP (Cold Process) swirl technique requires precise temperature control between 120-130degF to achieve smooth, defined patterns, while HP (Hot Process) swirls benefit from manipulating soap's gel phase for vibrant color blending. Using spatulas or spoons with gentle, fluid motions prevents overmixing and preserves the distinct swirl design in both methods. Incorporating contrasting colors with varying pigment densities enhances visual depth, creating eye-catching, artisanal soap bars.

CP Swirl Technique vs HP Swirl Technique Infographic

bizdif.com

bizdif.com