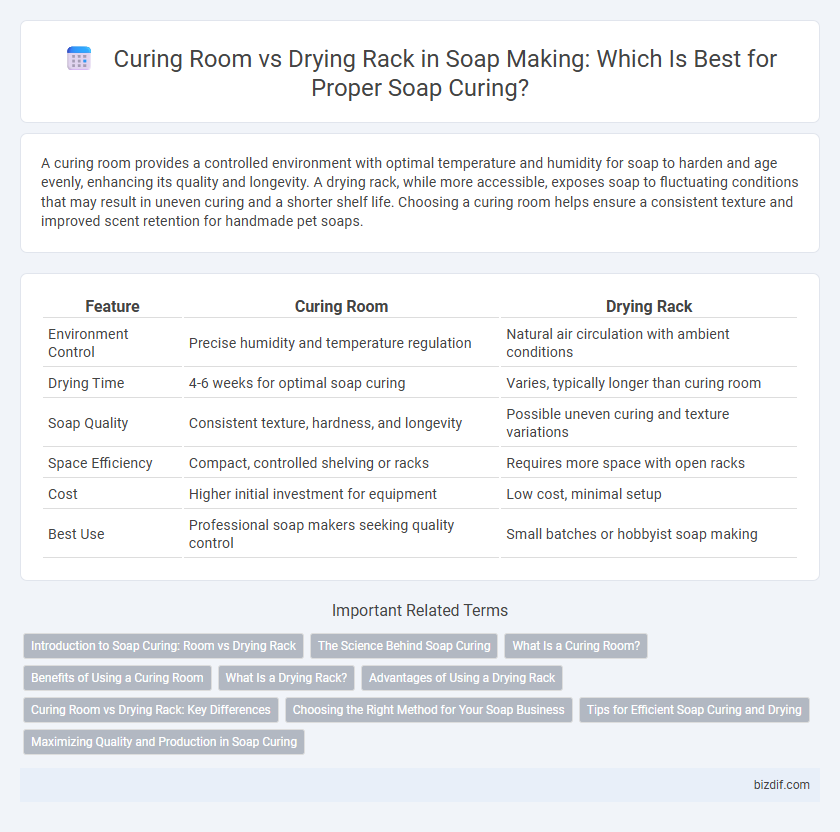

A curing room provides a controlled environment with optimal temperature and humidity for soap to harden and age evenly, enhancing its quality and longevity. A drying rack, while more accessible, exposes soap to fluctuating conditions that may result in uneven curing and a shorter shelf life. Choosing a curing room helps ensure a consistent texture and improved scent retention for handmade pet soaps.

Table of Comparison

| Feature | Curing Room | Drying Rack |

|---|---|---|

| Environment Control | Precise humidity and temperature regulation | Natural air circulation with ambient conditions |

| Drying Time | 4-6 weeks for optimal soap curing | Varies, typically longer than curing room |

| Soap Quality | Consistent texture, hardness, and longevity | Possible uneven curing and texture variations |

| Space Efficiency | Compact, controlled shelving or racks | Requires more space with open racks |

| Cost | Higher initial investment for equipment | Low cost, minimal setup |

| Best Use | Professional soap makers seeking quality control | Small batches or hobbyist soap making |

Introduction to Soap Curing: Room vs Drying Rack

Soap curing requires controlled environments to ensure proper saponification and moisture evaporation. A curing room offers stable temperature and humidity levels, promoting even drying and enhancing soap hardness and longevity. Drying racks provide airflow and space-efficient stacking but may expose soap to variable conditions, potentially affecting the final texture and curing time.

The Science Behind Soap Curing

Soap curing involves a chemical process called saponification, where oils and lye react to form soap while excess water evaporates. A curing room provides controlled temperature and humidity crucial for optimal evaporation and hardening, reducing glycerin sweat and improving longevity. Drying racks offer airflow but lack environmental control, making curing rooms more effective for consistent soap quality and complete curing.

What Is a Curing Room?

A curing room is a controlled environment designed to optimize temperature, humidity, and airflow for soap aging, ensuring soap bars become harder and milder over weeks. Unlike drying racks, which rely on ambient conditions, a curing room accelerates saponification and evaporation of excess water for superior soap quality. This space maintains consistent conditions critical for preventing mold growth and enhancing the soap's longevity and performance.

Benefits of Using a Curing Room

A curing room provides controlled temperature and humidity levels essential for consistent soap hardening and moisture reduction, ensuring higher quality bars. This environment minimizes the risk of discoloration and microbial growth compared to open drying racks. Enhanced air circulation in curing rooms accelerates saponification and extends soap shelf life.

What Is a Drying Rack?

A drying rack in soap making is a specialized structure designed to hold freshly cut soap bars, allowing air to circulate freely around each piece for optimal drying. Unlike a curing room that maintains controlled temperature and humidity for long-term soap maturation, a drying rack provides immediate space to dry soaps after cutting, preventing deformation and promoting proper hardening. Effective air circulation on drying racks accelerates moisture evaporation, essential for high-quality soap texture before transferring to the curing room.

Advantages of Using a Drying Rack

Using a drying rack in soap making allows for optimal airflow around each bar, accelerating the drying process and preventing moisture buildup that can lead to softness or mold. Drying racks maximize space efficiency by enabling multiple bars to cure simultaneously while ensuring even exposure to air, which promotes uniform hardening. The ease of access and visibility of soaps on racks also facilitates quality inspection and handling without disrupting the curing environment.

Curing Room vs Drying Rack: Key Differences

A curing room provides a controlled environment with consistent temperature and humidity levels essential for soap to harden and mature, while a drying rack offers an open-air space primarily for initial drying stages. Soaps cured in a curing room typically develop a harder texture and longer shelf life due to reduced moisture content. Drying racks are more suitable for quick evaporation but lack the environmental control necessary for optimal soap curing.

Choosing the Right Method for Your Soap Business

Selecting the appropriate curing method is crucial for soap businesses aiming to ensure product quality and longevity. A curing room provides controlled temperature and humidity, promoting consistent soap hardness and extended shelf life, while drying racks offer airflow and space efficiency but may result in uneven drying or contamination risks. Evaluating factors such as batch size, workspace limitations, and desired production speed will guide soap makers toward the optimal choice between curing rooms and drying racks.

Tips for Efficient Soap Curing and Drying

Maintain consistent airflow and humidity levels in the curing room to prevent soap from developing a sticky surface or cracking prematurely. Arrange soaps on drying racks with adequate spacing to maximize air circulation, speeding up the evaporation of excess moisture. Use a timer to rotate soap batches regularly, ensuring even drying and optimal hardness before packaging.

Maximizing Quality and Production in Soap Curing

A dedicated curing room provides consistent temperature and humidity control essential for soap to fully saponify and harden, enhancing quality by preventing cracking or discoloration. In contrast, drying racks offer airflow benefits but lack environmental stability, potentially leading to inconsistent curing results. Optimizing soap curing involves balancing controlled ambient conditions with adequate air circulation to maximize production efficiency and end-product integrity.

Curing Room vs Drying Rack Infographic

bizdif.com

bizdif.com