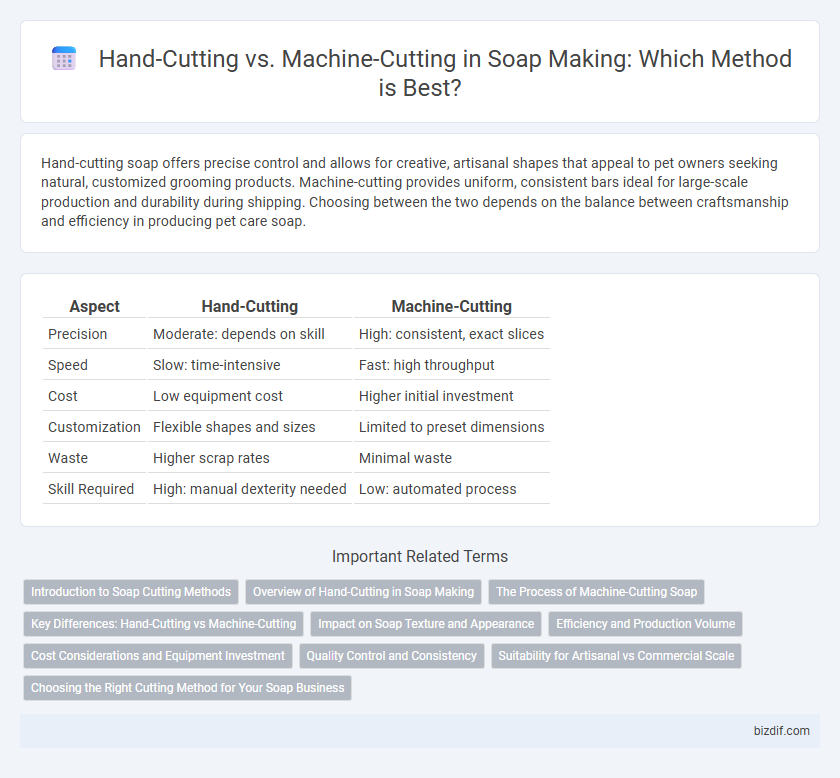

Hand-cutting soap offers precise control and allows for creative, artisanal shapes that appeal to pet owners seeking natural, customized grooming products. Machine-cutting provides uniform, consistent bars ideal for large-scale production and durability during shipping. Choosing between the two depends on the balance between craftsmanship and efficiency in producing pet care soap.

Table of Comparison

| Aspect | Hand-Cutting | Machine-Cutting |

|---|---|---|

| Precision | Moderate: depends on skill | High: consistent, exact slices |

| Speed | Slow: time-intensive | Fast: high throughput |

| Cost | Low equipment cost | Higher initial investment |

| Customization | Flexible shapes and sizes | Limited to preset dimensions |

| Waste | Higher scrap rates | Minimal waste |

| Skill Required | High: manual dexterity needed | Low: automated process |

Introduction to Soap Cutting Methods

Soap cutting methods vary primarily between hand-cutting and machine-cutting techniques, each affecting the final product's texture and uniformity. Hand-cutting allows artisanal customization and retains natural edges, making it ideal for small-batch or specialty soaps. Machine-cutting optimizes efficiency and consistency, producing evenly sized bars ideal for large-scale commercial production.

Overview of Hand-Cutting in Soap Making

Hand-cutting in soap making involves slicing soap bars manually using a knife or wire cutter, allowing artisans precise control over bar size and thickness. This traditional method enhances the uniqueness of each batch, often preferred for small-scale or artisanal soap production. Hand-cutting preserves intricate designs and textures that machines may overlook, contributing to a handcrafted aesthetic valued in premium soaps.

The Process of Machine-Cutting Soap

Machine-cutting soap involves automated blades that slice soap logs into uniform bars with precise dimensions, enhancing production efficiency. This method reduces labor intensity and increases consistency in texture and weight across batches. Industrial machines often include conveyors and programmable settings to handle large-scale soap manufacturing demands.

Key Differences: Hand-Cutting vs Machine-Cutting

Hand-cutting soap offers precise control over bar size and shape, allowing artisan creators to customize each batch with unique variations and textures. Machine-cutting ensures uniformity and speed, producing consistent, symmetrical bars suitable for large-scale production. While hand-cutting emphasizes craftsmanship and small-batch uniqueness, machine-cutting prioritizes efficiency and standardization in soap manufacturing.

Impact on Soap Texture and Appearance

Hand-cutting soap results in uneven edges and varied thickness, creating a rustic, artisanal texture with unique character, while machine-cutting produces uniform bars with smooth, consistent edges and precise dimensions. This precision in machine-cut soap enhances visual appeal and consistency in size, contributing to better product presentation and packaging efficiency. Variations from hand-cut soaps may appeal to niche markets seeking authenticity and handcrafted aesthetics.

Efficiency and Production Volume

Hand-cutting soap offers greater precision and artistic control, ideal for small-batch or artisanal soap production where unique shapes and textures are prioritized. Machine-cutting significantly boosts efficiency and production volume, enabling consistent, uniform bars to be produced rapidly and in large quantities, which is essential for commercial soap manufacturers. Investing in automated cutting machinery reduces labor costs and minimizes material waste, enhancing overall operational productivity.

Cost Considerations and Equipment Investment

Hand-cutting soap requires minimal initial investment with basic tools like knives and cutting boards, making it cost-effective for small-scale or artisanal production. Machine-cutting demands higher upfront capital for specialized equipment but increases efficiency and consistency, reducing labor costs over time. Businesses must weigh the trade-off between low initial costs and long-term productivity gains when choosing between hand-cutting and machine-cutting methods.

Quality Control and Consistency

Hand-cutting soap allows artisans to closely monitor texture and adjust cuts for unique bar sizes, enhancing craftsmanship and quality control. Machine-cutting ensures uniform bar dimensions and consistent weight, which is crucial for large-scale production and meeting regulatory standards. Both methods impact the final product's appearance and customer satisfaction, with hand-cutting offering customization and machine-cutting delivering efficiency.

Suitability for Artisanal vs Commercial Scale

Hand-cutting soap provides precise control and artisanal quality, making it ideal for small batches and custom designs in boutique soap making. Machine-cutting enhances efficiency and uniformity, supporting large-scale commercial production with consistent sizing and reduced labor costs. Artisanal soap makers benefit from hand-cutting to maintain uniqueness, while commercial operations rely on machines for scalability and productivity.

Choosing the Right Cutting Method for Your Soap Business

Hand-cutting soap offers precise control over bar size and shape, ideal for artisan soap makers prioritizing customization and small batches. Machine-cutting enhances production speed and uniformity, suitable for businesses scaling up and requiring consistent product dimensions. Selecting the right cutting method depends on factors like batch volume, desired bar aesthetics, and cost-efficiency in your soap manufacturing process.

Hand-Cutting vs Machine-Cutting Infographic

bizdif.com

bizdif.com