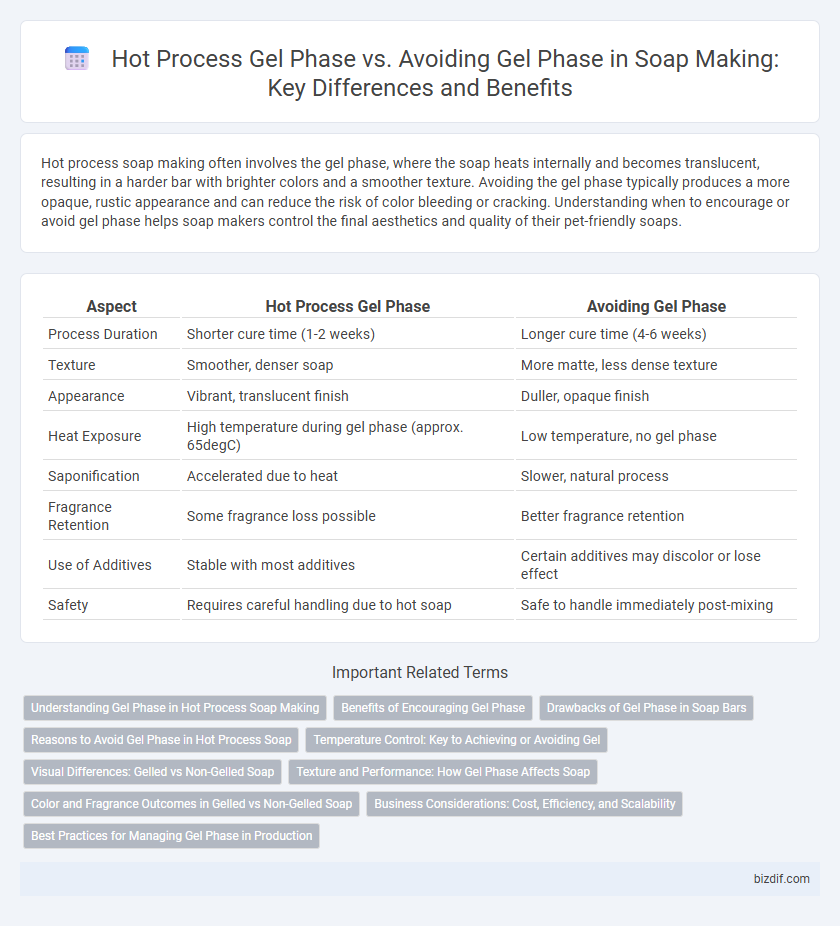

Hot process soap making often involves the gel phase, where the soap heats internally and becomes translucent, resulting in a harder bar with brighter colors and a smoother texture. Avoiding the gel phase typically produces a more opaque, rustic appearance and can reduce the risk of color bleeding or cracking. Understanding when to encourage or avoid gel phase helps soap makers control the final aesthetics and quality of their pet-friendly soaps.

Table of Comparison

| Aspect | Hot Process Gel Phase | Avoiding Gel Phase |

|---|---|---|

| Process Duration | Shorter cure time (1-2 weeks) | Longer cure time (4-6 weeks) |

| Texture | Smoother, denser soap | More matte, less dense texture |

| Appearance | Vibrant, translucent finish | Duller, opaque finish |

| Heat Exposure | High temperature during gel phase (approx. 65degC) | Low temperature, no gel phase |

| Saponification | Accelerated due to heat | Slower, natural process |

| Fragrance Retention | Some fragrance loss possible | Better fragrance retention |

| Use of Additives | Stable with most additives | Certain additives may discolor or lose effect |

| Safety | Requires careful handling due to hot soap | Safe to handle immediately post-mixing |

Understanding Gel Phase in Hot Process Soap Making

Gel phase in hot process soap making occurs when the soap mixture reaches a high temperature, causing it to thicken and become translucent, which accelerates saponification and enhances color vibrancy. Embracing gel phase results in a harder, more durable bar with less curing time, while avoiding gel phase can produce a milder scent and more textured finish. Controlling the temperature and insulation during the hot process allows soap makers to manipulate gel phase for desired soap qualities.

Benefits of Encouraging Gel Phase

Encouraging the gel phase in hot process soap making enhances soap hardness and durability by allowing saponification to complete more thoroughly while trapped heat accelerates the chemical reaction. This phase also results in a smoother, more uniform texture and a more vibrant color retention compared to avoiding gel phase, which can produce a softer bar with uneven curing. Additionally, gel phase soaps often have better longevity and resist sweating or glycerin dew, improving shelf life and user experience.

Drawbacks of Gel Phase in Soap Bars

The gel phase in hot process soap making can cause uneven coloring and a translucent appearance, leading to less visually appealing bars. Soap bars undergoing gel phase tend to be softer and may retain excess moisture, which reduces shelf life and increases the risk of microbial growth. Avoiding gel phase helps maintain a consistent, matte finish and firmer texture, improving overall soap quality and durability.

Reasons to Avoid Gel Phase in Hot Process Soap

Avoiding gel phase in hot process soap prevents uneven heating, which can cause discoloration and unpredictable texture in the final product. Gel phase accelerates saponification, increasing the risk of soap overheating and cracking. Maintaining a lower temperature ensures consistent curing, preserving the soap's clarity and hardness.

Temperature Control: Key to Achieving or Avoiding Gel

Temperature control is crucial in hot process soap making, as maintaining a consistent heat between 130degF and 160degF ensures the soap enters the gel phase, accelerating saponification and producing a harder bar faster. Avoiding the gel phase requires cooling the soap below 110degF after pouring to prevent the internal heat buildup typical in insulated molds, resulting in a milder texture and less translucent appearance. Precise monitoring with a thermometer allows soap makers to manipulate gelation, optimizing bar quality and curing time.

Visual Differences: Gelled vs Non-Gelled Soap

Hot process soap features a distinctive gelled phase where the soap batter becomes translucent and gel-like due to heat, resulting in vibrant, uniform color and a smooth texture. Non-gelled soap lacks this phase, appearing opaque, often matte, and with a more rustic or uneven color distribution. The visual transparency and depth in gelled soap contrast sharply with the cloudy, solid appearance of soap that avoids the gel phase.

Texture and Performance: How Gel Phase Affects Soap

Gel phase in hot process soap occurs when the soap heats up and transitions to a gel-like consistency, intensifying the color and creating a smoother, shinier texture. Avoiding gel phase results in a more opaque, matte finish with a slightly softer texture but may reduce the soap's hardness and longevity. Performance-wise, gel phase soap often lasts longer and is less prone to sweating, improving overall usability and customer satisfaction.

Color and Fragrance Outcomes in Gelled vs Non-Gelled Soap

Hot process soap undergoes gel phase, resulting in brighter, more vibrant colors as the heat intensifies pigment activation, while fragrance tends to retain more of its original scent profile due to accelerated curing that reduces oxidative loss. Avoiding gel phase in cold process soap preserves softer, muted colors since the soap cools gradually, minimizing heat impact on pigments and fragrance compounds, although some scent fading may occur over time. Choosing between gelled and non-gelled soap affects both the visual appeal and aromatic quality, with gel phase enhancing color brilliance and fragrance stability but potentially altering scent nuances.

Business Considerations: Cost, Efficiency, and Scalability

Hot Process soap making's gel phase accelerates saponification, reducing cure time and increasing production efficiency, which benefits scalability and lowers labor costs. Avoiding the gel phase extends curing duration, resulting in longer inventory turnover but can reduce energy expenses as lower temperatures are maintained. Businesses must weigh faster market readiness against operational costs when choosing between adopting hot process gel phase or cold process methods.

Best Practices for Managing Gel Phase in Production

Managing the gel phase in hot process soap making requires maintaining consistent mold temperatures between 140degF and 160degF to ensure uniform heat distribution and optimal saponification. Insulating molds with towels or blankets during curing helps retain heat while avoiding overheating that causes cracking or uneven gel phases. Monitoring the soap's pH and timing unmolding precisely prevents premature gel phase or incomplete curing, enhancing product quality and batch consistency.

Hot Process Gel Phase vs Avoiding Gel Phase Infographic

bizdif.com

bizdif.com