Saponification rate directly influences trace time in soap making, as faster saponification leads to quicker thickening of the soap mixture. Managing the balance between the saponification rate and trace time is essential for achieving the desired consistency and workability. Understanding this relationship helps soap makers optimize formulations for both cold process and hot process techniques.

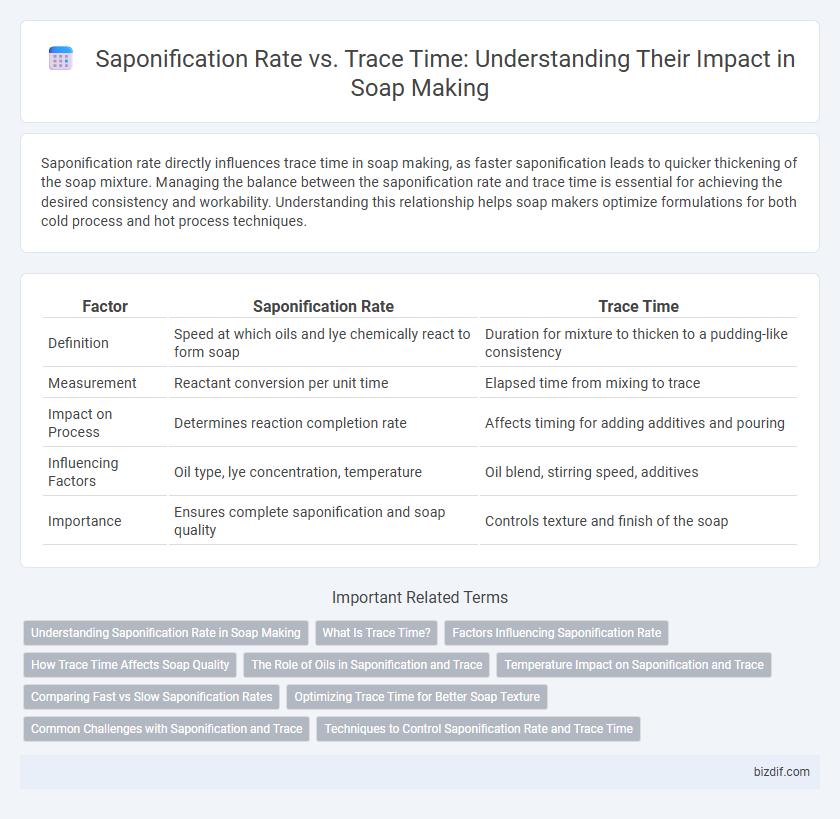

Table of Comparison

| Factor | Saponification Rate | Trace Time |

|---|---|---|

| Definition | Speed at which oils and lye chemically react to form soap | Duration for mixture to thicken to a pudding-like consistency |

| Measurement | Reactant conversion per unit time | Elapsed time from mixing to trace |

| Impact on Process | Determines reaction completion rate | Affects timing for adding additives and pouring |

| Influencing Factors | Oil type, lye concentration, temperature | Oil blend, stirring speed, additives |

| Importance | Ensures complete saponification and soap quality | Controls texture and finish of the soap |

Understanding Saponification Rate in Soap Making

Saponification rate in soap making refers to the speed at which oils and lye react to form soap, directly affecting trace time--the moment when the mixture thickens to a pudding-like consistency. Oils with higher unsaturation levels typically increase the saponification rate, resulting in faster trace times and influencing soap texture and curing duration. Monitoring saponification rate helps optimize formulation for desired hardness, moisturizing properties, and overall soap quality.

What Is Trace Time?

Trace time refers to the duration between mixing lye and oils until the soap batter thickens to a pudding-like consistency, indicating the start of saponification. It is a critical phase where chemical reactions convert fats into soap, and achieving the correct trace ensures proper texture and quality. Monitoring trace time helps soap makers control the final product's hardness, lather, and curing time.

Factors Influencing Saponification Rate

Saponification rate depends largely on factors such as the type of oils used, their fatty acid profiles, and the concentration of lye in the mixture. Temperature plays a critical role by accelerating or slowing down the chemical reaction between fats and alkali, directly impacting the trace time. The presence of additives like sodium lactate or salt can also modify the saponification rate by altering the soap's consistency and curing time.

How Trace Time Affects Soap Quality

Trace time directly influences soap quality by determining the texture and hardness of the finished product; shorter trace times typically yield smoother, creamier soaps while longer trace times promote a denser, more durable bar. Saponification rate depends on factors such as temperature, lye concentration, and oil type, which in turn affect how quickly trace is achieved and the resulting soap properties. Optimal control of trace time ensures balanced saponification, enhancing the soap's longevity, cleansing ability, and skin feel.

The Role of Oils in Saponification and Trace

The saponification rate of oils directly influences trace time in soap making, with oils high in saturated fats like coconut and palm oils accelerating the saponification process and resulting in a faster trace. Oils rich in unsaturated fats, such as olive and almond oils, slow down the saponification rate, leading to a longer trace and more workable soap batter. Understanding the unique fatty acid composition of each oil helps soap makers control trace consistency and cure time for optimal soap quality.

Temperature Impact on Saponification and Trace

Higher temperatures accelerate the saponification rate by increasing the reaction kinetics between oils and lye, leading to a faster trace time in soap making. Trace, the point where the mixture thickens, is reached more quickly at elevated temperatures due to enhanced molecular activity and emulsification. Optimal temperature control is crucial for managing trace time and ensuring consistent soap texture and quality.

Comparing Fast vs Slow Saponification Rates

Fast saponification rates in soap making result in quicker trace times, enabling rapid emulsification of oils and lye, which is ideal for simple recipes and agile molding. Slow saponification rates extend trace time, allowing for finer control over texture and the incorporation of additives, essential for complex or decorative soaps. Understanding the balance between saponification rate and trace time optimizes the soap's quality and customization potential.

Optimizing Trace Time for Better Soap Texture

Optimizing trace time is crucial for achieving the ideal saponification rate, which directly impacts soap texture and quality. A balanced trace time allows the lye and oils to react efficiently, promoting smooth consistency and reducing the risk of graininess or separation. Precise control over temperature and stirring methods accelerates trace, enhancing the final soap's hardness and lather stability.

Common Challenges with Saponification and Trace

Saponification rate directly influences trace time, where a faster saponification can lead to premature thickening, making it difficult to incorporate additives and achieve uniform texture. Common challenges include uneven mixing and temperature fluctuations that disrupt the consistent formation of soap nuclei, resulting in patchy or lumpy batches. Managing these factors ensures a controlled trace, optimizing the chemical reaction between oils and lye for high-quality soaps.

Techniques to Control Saponification Rate and Trace Time

Controlling saponification rate and trace time in soap making involves precise temperature management and ingredient adjustments, such as using cooler temperatures to slow alkali reaction and adding water or sugar to extend trace time. Utilizing stirring techniques like intermittent mixing reduces heat buildup, allowing for a more controlled emulsification process. Adjusting the concentration and type of lye, along with selecting oils with varying saturation levels, further optimizes saponification speed and ensures precise trace development.

Saponification Rate vs Trace Time Infographic

bizdif.com

bizdif.com