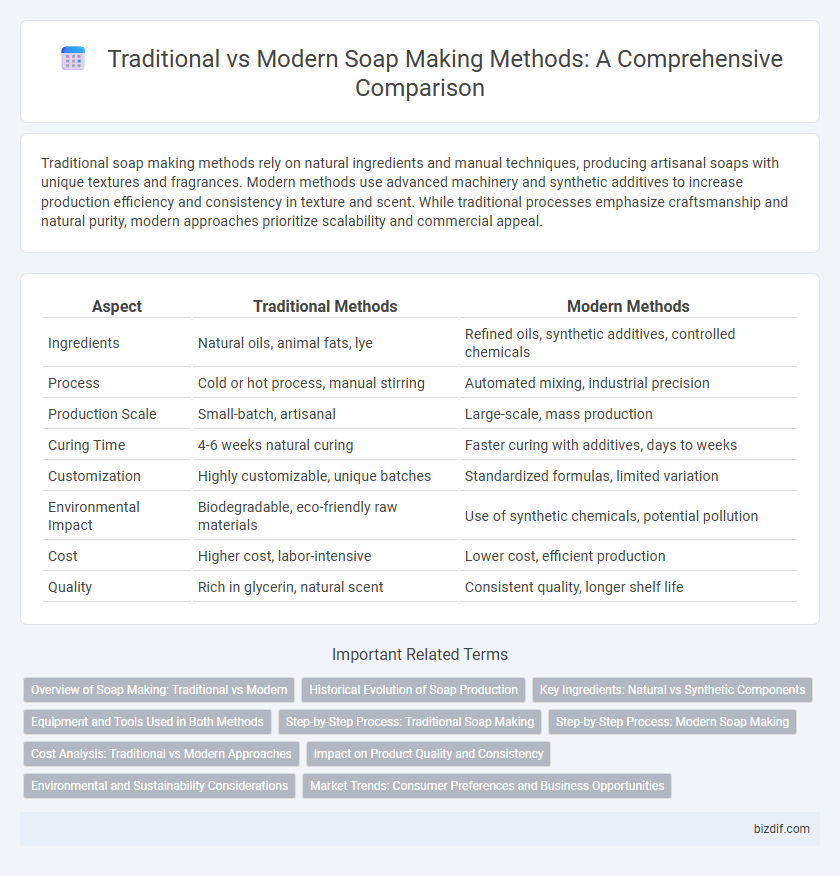

Traditional soap making methods rely on natural ingredients and manual techniques, producing artisanal soaps with unique textures and fragrances. Modern methods use advanced machinery and synthetic additives to increase production efficiency and consistency in texture and scent. While traditional processes emphasize craftsmanship and natural purity, modern approaches prioritize scalability and commercial appeal.

Table of Comparison

| Aspect | Traditional Methods | Modern Methods |

|---|---|---|

| Ingredients | Natural oils, animal fats, lye | Refined oils, synthetic additives, controlled chemicals |

| Process | Cold or hot process, manual stirring | Automated mixing, industrial precision |

| Production Scale | Small-batch, artisanal | Large-scale, mass production |

| Curing Time | 4-6 weeks natural curing | Faster curing with additives, days to weeks |

| Customization | Highly customizable, unique batches | Standardized formulas, limited variation |

| Environmental Impact | Biodegradable, eco-friendly raw materials | Use of synthetic chemicals, potential pollution |

| Cost | Higher cost, labor-intensive | Lower cost, efficient production |

| Quality | Rich in glycerin, natural scent | Consistent quality, longer shelf life |

Overview of Soap Making: Traditional vs Modern

Traditional soap making relies on cold or hot process techniques using natural fats and lye, emphasizing craftsmanship and slower curing times. Modern methods incorporate industrial automation, synthetic additives, and faster saponification processes to increase efficiency and consistency. The contrast highlights a balance between artisanal quality and mass production scalability in soap manufacturing.

Historical Evolution of Soap Production

Traditional soap making relied on saponification using natural fats and alkaline substances like wood ash, a technique dating back to ancient Babylon around 2800 BC. Modern methods utilize industrial processes such as continuous saponification and the addition of synthetic detergents to enhance efficiency and product consistency. The historical evolution highlights a shift from artisanal batch production to large-scale manufacturing driven by technological advancements and chemical innovation.

Key Ingredients: Natural vs Synthetic Components

Traditional soap making relies heavily on natural ingredients such as olive oil, coconut oil, and lye derived from wood ash, promoting skin-friendly and biodegradable properties. Modern soap production incorporates synthetic components like sodium lauryl sulfate and artificial fragrances, enhancing lather and scent consistency but potentially causing skin irritation. Understanding the contrast between natural oils and synthetic additives is crucial for consumers prioritizing ingredient transparency and environmental impact in soap products.

Equipment and Tools Used in Both Methods

Traditional soap making relies on basic equipment such as wooden spoons, clay molds, and open-fire kettles, emphasizing manual stirring and natural curing processes. Modern methods utilize advanced tools like automated mixers, stainless steel molds, and temperature-controlled heating systems, enabling precise ingredient measurements and faster production. The shift from handcrafted tools to mechanized equipment enhances efficiency, consistency, and scalability in soap manufacturing.

Step-by-Step Process: Traditional Soap Making

Traditional soap making involves a step-by-step process starting with mixing lye (sodium hydroxide) and water, followed by carefully combining it with animal fats or vegetable oils. The mixture is stirred continuously until it reaches "trace," a thickened consistency indicating the chemical reaction called saponification is underway. After pouring into molds, the soap is left to cure for 4 to 6 weeks, ensuring it hardens and any excess lye neutralizes for safe use.

Step-by-Step Process: Modern Soap Making

Modern soap making employs precise measurement of ingredients, combining oils and lye solution under controlled temperatures to ensure consistent saponification. Automated mixing and molding systems streamline the blending, curing, and cutting stages, enhancing efficiency and product uniformity. Advanced techniques such as cold process and hot process soap making integrate temperature monitoring and accelerated curing times compared to traditional hand-mixing methods.

Cost Analysis: Traditional vs Modern Approaches

Traditional soap making methods involve manual labor and natural ingredients, often resulting in higher material costs but lower energy consumption. Modern soap production utilizes automated processes and synthetic additives, increasing initial capital investment but reducing labor costs and improving scalability. Cost analysis reveals traditional methods suit small-scale artisans seeking authenticity, while modern approaches optimize expenses for mass production and market competitiveness.

Impact on Product Quality and Consistency

Traditional soap making methods, such as cold process and hot process, often result in unique textures and natural variations in each batch, reflecting artisanal craftsmanship but sometimes lacking uniform consistency. Modern methods, including automated mixing and controlled curing environments, enhance product quality by ensuring consistent chemical composition and appearance across large-scale production. Implementing advanced quality control techniques in modern soap making significantly reduces impurities and improves shelf life, contributing to reliable customer satisfaction.

Environmental and Sustainability Considerations

Traditional soap making methods often utilize natural, biodegradable ingredients like animal fats and plant oils, resulting in minimal environmental impact and enhanced sustainability. Modern methods, while efficient and scalable, frequently rely on synthetic chemicals and palm oil derivatives, contributing to deforestation and chemical pollution. Sustainable soap production increasingly emphasizes eco-friendly sourcing, waste reduction, and the use of renewable energy to balance industrial demands with environmental preservation.

Market Trends: Consumer Preferences and Business Opportunities

Traditional soap making methods emphasize natural ingredients and artisanal craftsmanship, appealing to consumers seeking organic and eco-friendly products. Modern methods leverage advanced manufacturing technologies to produce consistent, scalable, and innovative formulations that meet mass-market demand for convenience and variety. Rising consumer preferences for sustainable and ethically sourced soaps drive business opportunities in both handmade niche markets and high-efficiency production sectors, fostering diverse market growth.

Traditional Methods vs Modern Methods Infographic

bizdif.com

bizdif.com