Rebatching and milling are two effective methods for refining soap, each offering unique benefits for pet-friendly products. Rebatching involves melting down existing soap bars and adding ingredients to customize properties, ensuring gentle cleansing ideal for sensitive pet skin. Milling, on the other hand, mechanically refines soap to create a smoother, more concentrated bar that lasts longer and provides a mild, luxurious lather suitable for pets.

Table of Comparison

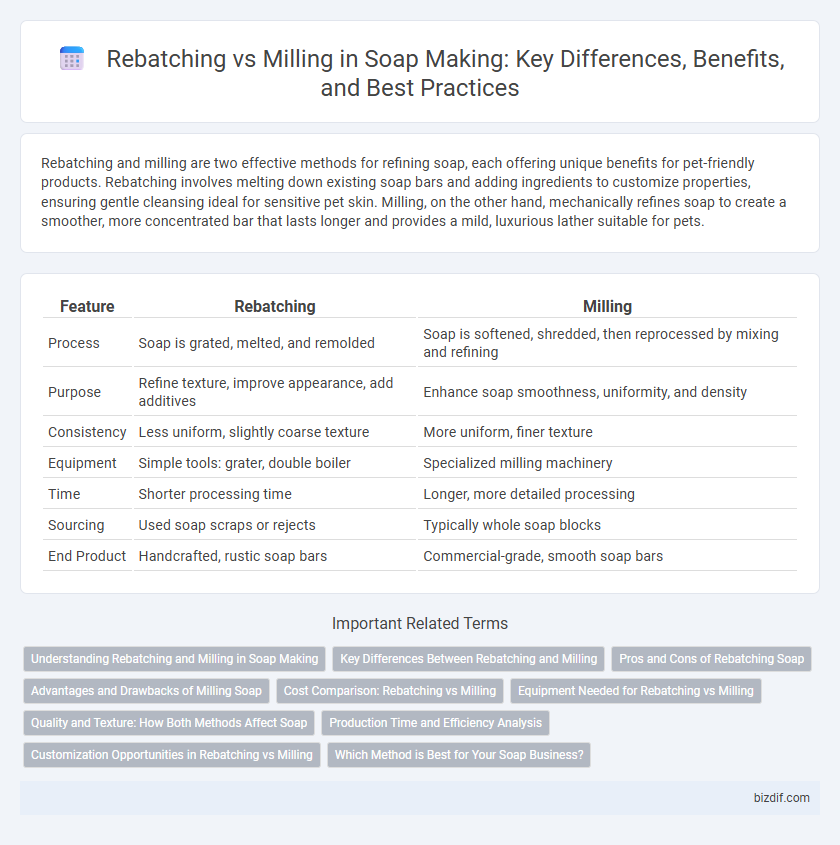

| Feature | Rebatching | Milling |

|---|---|---|

| Process | Soap is grated, melted, and remolded | Soap is softened, shredded, then reprocessed by mixing and refining |

| Purpose | Refine texture, improve appearance, add additives | Enhance soap smoothness, uniformity, and density |

| Consistency | Less uniform, slightly coarse texture | More uniform, finer texture |

| Equipment | Simple tools: grater, double boiler | Specialized milling machinery |

| Time | Shorter processing time | Longer, more detailed processing |

| Sourcing | Used soap scraps or rejects | Typically whole soap blocks |

| End Product | Handcrafted, rustic soap bars | Commercial-grade, smooth soap bars |

Understanding Rebatching and Milling in Soap Making

Rebatching in soap making involves melting previously cured soap chunks and remixing them to achieve uniform texture or to incorporate additives without starting from scratch. Milling processes the soap by repeatedly passing it through rollers to create a smooth, dense bar, improving consistency and removing excess moisture. Both techniques enhance soap quality but serve different purposes: rebatching is ideal for customizing small batches, while milling is suited for producing large volumes with improved texture.

Key Differences Between Rebatching and Milling

Rebatching involves melting and remolding cured soap to customize ingredients without altering the original saponification process, while milling is a mechanical technique that refines soap bars by grinding and pressing to create a smoother texture and higher glycerin content. Rebatching allows for small batch modifications with less equipment, whereas milling requires specialized machinery and is suited for producing uniform, high-quality bars at scale. The key difference lies in the process purpose: rebatching modifies soap composition post-curing, whereas milling enhances texture and consistency for commercial presentation.

Pros and Cons of Rebatching Soap

Rebatching soap offers the advantage of rescuing batches with imperfections such as uneven texture or excess water, allowing customization by adding fragrances or exfoliants before reshaping. It is a gentle process that preserves more oils and fragrances compared to milling, but it requires more time and labor to evenly melt, mix, and re-form the soap bars. A notable downside is that rebatching can result in a less consistent texture and slower curing time, potentially affecting the final soap quality and durability.

Advantages and Drawbacks of Milling Soap

Milling soap enhances texture and consistency by thoroughly blending and refining soap bars, resulting in a smoother, denser product with improved lather and longer-lasting qualities. This process allows for the incorporation of additives like fragrances or exfoliants more evenly throughout the soap. However, milling requires specialized equipment and increases production time and energy consumption, potentially raising costs and complexity in soap manufacturing.

Cost Comparison: Rebatching vs Milling

Rebatching soap typically incurs higher labor costs due to manual shredding and remelting, while milling involves expensive machinery and higher initial investment but reduces labor expenses over time. Milling yields a smoother, more uniform soap texture, potentially increasing product value and justifying higher production costs compared to rebatching. Overall, rebatching offers lower upfront equipment costs but increases operational expenses, whereas milling demands higher startup capital with improved efficiency and consistency impacting long-term profitability.

Equipment Needed for Rebatching vs Milling

Rebatching soap requires simple equipment such as a grater or food processor, a double boiler or slow cooker for melting, and molds for reshaping the soap. Milling soap demands more specialized tools, including a soap mill or refiner, rollers, and cutting machines to achieve a smoother, more uniform texture. The difference in equipment highlights the artisanal approach of rebatching versus the industrial precision involved in milling.

Quality and Texture: How Both Methods Affect Soap

Rebatching and milling both enhance soap quality by refining texture and improving uniformity; rebatching gently melts and remolds soap, preserving delicate additives for a smoother finish, while milling mechanically refines soap bars by breaking down particles into a denser, creamier consistency. Milling produces a finer, more homogeneous texture, ideal for luxury soaps with consistent lather and longevity, whereas rebatching maintains more of the original soap's character and can incorporate fragile ingredients without degradation. Understanding the effects on texture helps soap makers choose the method that best suits their product's quality goals and formulation requirements.

Production Time and Efficiency Analysis

Rebatching soap involves melting and reshaping previously cured soap, leading to longer production times but allowing for correction of imperfections and customization. Milling utilizes mechanical agitation to grind and refine soap, significantly reducing production time and enhancing uniformity and hardness. Milling proves more efficient for large-scale production due to faster processing and consistent quality outcomes.

Customization Opportunities in Rebatching vs Milling

Rebatching offers extensive customization opportunities by allowing soap makers to add delicate ingredients like essential oils, herbs, and colorants without degradation, ensuring preservation of fragrance and texture. Milling provides a more homogeneous and refined soap base but limits ingredient additions due to the high temperatures and intense mixing involved. Soap artisans seeking precise personalization often prefer rebatching for its gentle process that supports tailored formulations.

Which Method is Best for Your Soap Business?

Rebatching preserves the original soap's qualities by melting and reforming it, ideal for small batches or salvaging imperfect soap. Milling, a more industrial process, refines soap by removing impurities and enhancing texture, suited for higher volume production and consistent quality. Choosing between rebatching and milling depends on your business scale, desired soap texture, and production efficiency.

Rebatching vs Milling Infographic

bizdif.com

bizdif.com