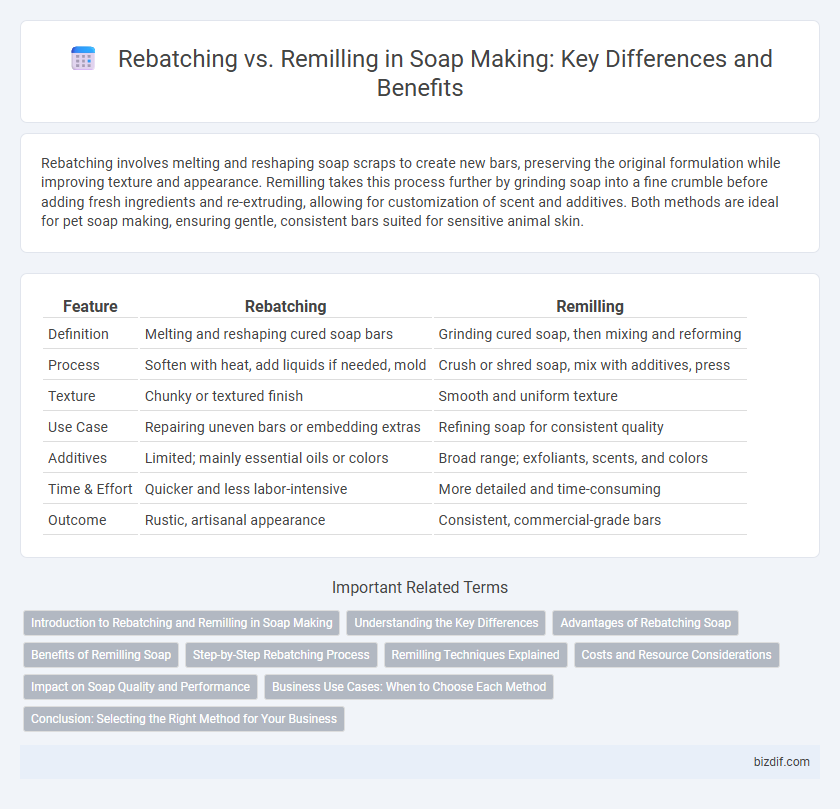

Rebatching involves melting and reshaping soap scraps to create new bars, preserving the original formulation while improving texture and appearance. Remilling takes this process further by grinding soap into a fine crumble before adding fresh ingredients and re-extruding, allowing for customization of scent and additives. Both methods are ideal for pet soap making, ensuring gentle, consistent bars suited for sensitive animal skin.

Table of Comparison

| Feature | Rebatching | Remilling |

|---|---|---|

| Definition | Melting and reshaping cured soap bars | Grinding cured soap, then mixing and reforming |

| Process | Soften with heat, add liquids if needed, mold | Crush or shred soap, mix with additives, press |

| Texture | Chunky or textured finish | Smooth and uniform texture |

| Use Case | Repairing uneven bars or embedding extras | Refining soap for consistent quality |

| Additives | Limited; mainly essential oils or colors | Broad range; exfoliants, scents, and colors |

| Time & Effort | Quicker and less labor-intensive | More detailed and time-consuming |

| Outcome | Rustic, artisanal appearance | Consistent, commercial-grade bars |

Introduction to Rebatching and Remilling in Soap Making

Rebatching and remilling are advanced soap-making techniques used to refine and salvage soap batches by melting and reprocessing them. Rebatching involves grating or chopping cured soap and dissolving it in a heated liquid to create a uniform texture, while remilling entails processing soap paste through a mill to achieve a smoother consistency and enhanced blend of ingredients. Both methods improve soap quality by correcting texture inconsistencies and incorporating additives more evenly.

Understanding the Key Differences

Rebatching involves melting and reshaping cured soap to correct texture or incorporate additives, preserving the original soap base's qualities, while remilling entails processing soap noodles through a mill to achieve a finer, more consistent texture and uniform color. Rebatching is ideal for small batches or salvaging soap, whereas remilling suits large-scale production for improving soap quality and appearance. Understanding these differences helps soap makers choose the appropriate technique based on desired texture, production scale, and ingredient integration.

Advantages of Rebatching Soap

Rebatching soap allows for precise control over the final texture and ingredients, making it ideal for incorporating sensitive additives that might degrade during original saponification. This method reduces the risk of lye spots and ensures a uniform, consistent bar by melting and reforming pre-cured soap, enhancing both appearance and performance. Rebatching also minimizes waste since imperfect or leftover soap can be reused, improving overall production efficiency.

Benefits of Remilling Soap

Remilling soap enhances the quality and texture by thoroughly reprocessing soap bars to achieve a smoother, more uniform consistency. This technique allows for the incorporation of additional ingredients, such as fragrances, colorants, and exfoliants, improving the final product's aesthetic appeal and functionality. Remilling also increases soap bar hardness and longevity, resulting in a superior user experience compared to rebatched soap.

Step-by-Step Rebatching Process

Rebatching involves shredding cured soap before gently melting it with a small amount of liquid to create a pliable mixture, allowing for the incorporation of additives like essential oils or colorants. The softened soap is then pressed into molds, ensuring even texture and removing any unwanted lumps. Finally, the soap is left to dry and harden for several days, resulting in improved consistency and customized bars without compromising the original soap properties.

Remilling Techniques Explained

Remilling techniques involve melting down cured soap bars to create a uniform, smooth texture before molding. This process enhances color and scent integration while allowing for the addition of extra ingredients such as oils or fragrances. By carefully controlling temperature and stirring, remilling ensures consistent quality and prevents overheating that can degrade soap properties.

Costs and Resource Considerations

Rebatching soap involves melting and reshaping pre-made soap, which generally requires less initial investment in specialized equipment compared to remilling, where soap is shredded, refined, and reprocessed to improve texture and uniformity. Rebatching tends to consume fewer resources like energy and labor, making it more cost-effective for small-scale or hobbyist soap makers, while remilling often demands higher operational costs due to machinery and processing time but can improve product quality and reduce waste. Choosing between rebatching and remilling depends on balancing upfront equipment expenses, desired soap quality, production volume, and available resources.

Impact on Soap Quality and Performance

Rebatching involves melting and reshaping previously cured soap, often causing slight variations in texture and reducing lather quality due to partial fat degradation. Remilling refines soap by grinding and recombining ingredients before curing, enhancing uniformity, hardness, and improving creamy lather retention. Choosing remilling typically yields superior soap performance and longevity compared to rebatched batches, which may exhibit inconsistent quality.

Business Use Cases: When to Choose Each Method

Rebatching suits small-scale soap makers needing to salvage batches with texture or lye issues, enabling customization and cost-effective recovery. Remilling benefits larger businesses requiring uniformity and efficiency, as it refines and blends base soap for consistent quality and faster production. Choosing depends on production volume, desired control over formulation, and whether reclaiming faulty batches or streamlining manufacturing is the primary goal.

Conclusion: Selecting the Right Method for Your Business

Choosing between rebatching and remilling depends on your business goals, batch size, and desired soap texture. Rebatching suits small-scale or custom batches with minimal equipment, while remilling benefits large-scale producers aiming for consistent quality and efficiency. Evaluating production capacity, cost, and product consistency ensures the optimal soap making method for your operation.

Rebatching vs Remilling Infographic

bizdif.com

bizdif.com