Cutting soap by hand offers precise control for custom shapes and allows crafters to adjust thickness easily, making it ideal for small batches or artistic designs. Using a wire cutter speeds up the process, producing clean, uniform bars that ensure consistent curing and easier packaging. Choosing between the two methods depends on the batch size, desired aesthetics, and available tools for efficient soap making.

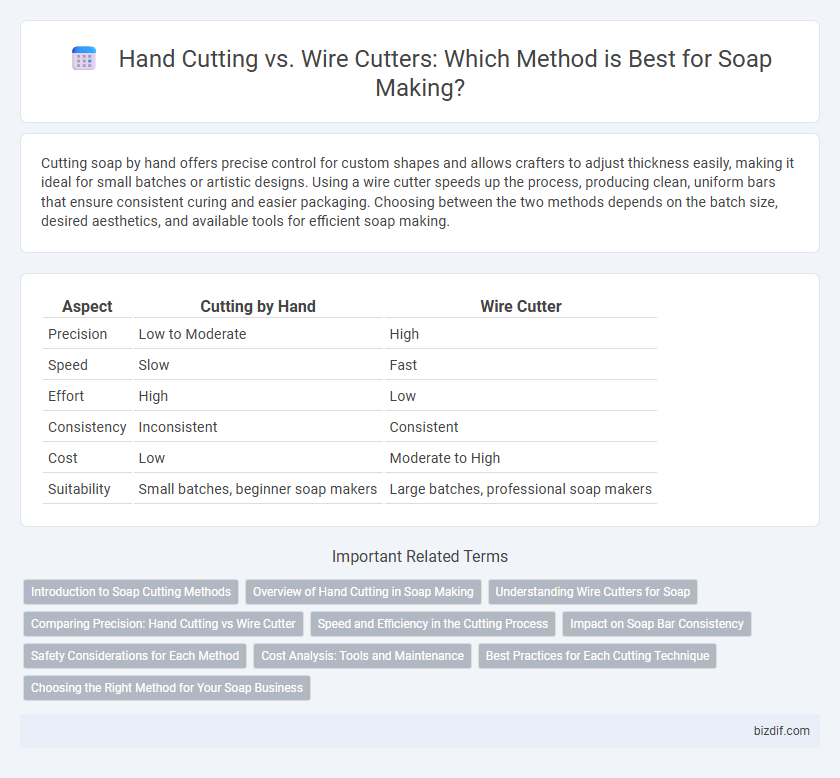

Table of Comparison

| Aspect | Cutting by Hand | Wire Cutter |

|---|---|---|

| Precision | Low to Moderate | High |

| Speed | Slow | Fast |

| Effort | High | Low |

| Consistency | Inconsistent | Consistent |

| Cost | Low | Moderate to High |

| Suitability | Small batches, beginner soap makers | Large batches, professional soap makers |

Introduction to Soap Cutting Methods

Soap cutting methods significantly impact the final product's appearance and texture, with hand cutting offering precision and control for artisan designs while wire cutters allow for faster, uniform slices ideal for larger batches. Hand cutting involves using a sharp knife or spatula to create custom shapes and sizes, enhancing creativity and detail. Wire cutters, typically made from stainless steel or nylon-coated wires, ensure smooth, consistent cuts and improve efficiency during bulk soap production.

Overview of Hand Cutting in Soap Making

Hand cutting in soap making offers precise control over the size and shape of soap bars, allowing artisans to create custom dimensions tailored to specific needs. This traditional method relies on simple tools like knives or spatulas, making it accessible for small-batch and hobby soap makers. Hand cutting preserves the texture and aesthetic qualities of cold and hot process soaps, providing a tactile connection to the craft.

Understanding Wire Cutters for Soap

Wire cutters for soap making use a thin, taut wire to create clean, even slices, minimizing pressure that can distort delicate soap bars. Hand cutting often leads to uneven edges and inconsistent sizes, while wire cutters ensure precise, repeatable cuts essential for professional-quality soap products. Choosing the right wire gauge and tension is crucial for slicing through various soap types without crumbling or compressing.

Comparing Precision: Hand Cutting vs Wire Cutter

Hand cutting soap offers personalized control but may result in uneven slices due to human variability, impacting the consistency of bar size and curing. Wire cutters provide uniform precision by applying consistent tension across the soap log, ensuring cleaner and more identical cuts suitable for scale production. Choosing between the two depends on the desired balance between artisanal craftsmanship and mass production efficiency in soap making.

Speed and Efficiency in the Cutting Process

Hand cutting soap offers greater control and customization but is significantly slower, requiring more effort and time for consistent slices. Wire cutters enhance speed and efficiency by producing uniform bars quickly, ideal for larger batches and commercial production. Choosing between the two depends on batch size and desired precision in soap slicing.

Impact on Soap Bar Consistency

Cutting soap by hand often results in uneven bar sizes, affecting curing time and uniformity in texture, while wire cutters produce consistently sized bars that promote even drying and a smoother finish. The precision of wire cutters minimizes air pockets and surface irregularities, leading to improved structural integrity and longer-lasting bars. Consistent cuts achieved with wire tools enhance the overall quality and aesthetic appeal of handmade soaps, ensuring a professional-grade product.

Safety Considerations for Each Method

Cutting soap by hand with a sharp knife requires careful attention to prevent slips and cuts, making it essential to use a stable surface and protective gloves for safety. Wire cutters offer more precise, uniform slices but pose risks such as wire breakage or snapping if not properly maintained, necessitating regular inspection and cautious handling. Both methods demand vigilance, but wire cutters can reduce manual strain and improve safety when used correctly.

Cost Analysis: Tools and Maintenance

Hand cutting soap requires minimal initial investment, typically involving only a simple knife or spatula, making it cost-effective for small-scale production. Wire cutters, while more expensive upfront due to tools like stainless steel wire frames, offer consistent slices and reduce material waste, which can lower long-term costs. Maintenance for wire cutters involves occasional wire replacement and frame cleaning, whereas hand-cutting tools demand less upkeep but may lead to irregular cuts, potentially affecting product uniformity and market value.

Best Practices for Each Cutting Technique

Hand cutting soap requires a steady grip and sharp knife to achieve consistent, smooth edges, with emphasis on safety to prevent accidents. Using a wire cutter offers precision and uniformity, especially for larger batches, ensuring evenly sized bars while minimizing waste. Maintaining equipment cleanliness and applying even pressure are essential best practices for both methods to produce professional-quality soap bars.

Choosing the Right Method for Your Soap Business

Choosing between hand cutting and wire cutters depends on your soap batch size and desired precision. Hand cutting offers flexibility and control ideal for small, artisanal batches, while wire cutters deliver uniform slices suited for large-scale production. Evaluating factors like production volume, consistency needs, and labor costs ensures optimal efficiency and product quality in your soap business.

Cutting by Hand vs Wire Cutter Infographic

bizdif.com

bizdif.com